Steel Formwork for Skyspare Export to Indonesia

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

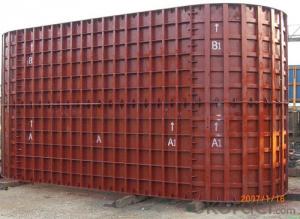

Introduction for Steel Formwork :

Steel Formwork:used in highway,railway,bridge,tunnel and shearing wall,etc.Our company CNBM which is one of the largest State-Owned Enterprises in China which established in 1984 , has gained the confirmation from the specialist of China Architecture Scence Institute, and has been used by many building operation units and has been highly praised.In 2014, the total turnover volume of CNBM exceeds US$410 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises !

Characteristic for Wholly Steel Formwork :

1. High Smooth Surface

2. Convex ling for Edge Rib

3. Specialized Connection Pin for Edge Rib Connection

4. High Stiffness for Steel Surface

5. Light Weight for saving producing cost

6. Fast Separate and Easy transport

7. Recycling using

8. Scientific and Reasonable design to meet different working condition

Parameter and Specification :

Code | Size (mm) | Weight (KG) | Code | Size (mm) | Weight (KG) |

P12021 | 1200*2100*55 | 102.96 | P4018 | 400*1800*55 | 28.3 |

P12018 | 1200*1800*55 | 88.4 | P4015 | 400*1500*55 | 23.8 |

P12015 | 1200*1500*55 | 74.15 | P4012 | 400*1200*55 | 19.1 |

P12012 | 1200*1200*55 | 60.11 | P4009 | 400*900*55 | 14.6 |

P10018 | 1000*1800*55 | 76.01 | P4007 | 400*750*55 | 12.3 |

P10015 | 1000*1500*55 | 63.96 | P4006 | 400*600*55 | 9.95 |

P10012 | 1000*1200*55 | 60.11 | P3018 | 300*1800*55 | 20.7 |

P10009 | 1000*900*55 | 39.32 | P3015 | 300*1500*55 | 17.4 |

P9018 | 900*1800*55 | 70.89 | P3012 | 300*1200*55 | 14 |

P9015 | 900*1500*55 | 59.47 | P3009 | 300*900*55 | 10.7 |

P9012 | 900*1200*55 | 48.03 | P3007 | 300*750*55 | 8.8 |

P7518 | 750*1800*55 | 57.8 | P3006 | 300*600*55 | 7.3 |

P7515 | 750*1500*55 | 48.47 | P3004 | 300*400*55 | 5.46 |

P7512 | 750*1200*55 | 39.16 | P2515 | 250*1500*55 | 15.17 |

P7509 | 750*900*55 | 29.85 | P2512 | 250*1200*55 | 12.24 |

P7507 | 750*750*55 | 24.81 | P2509 | 250*900*55 | 9.32 |

P6018 | 600*1800*55 | 43.1 | P2507 | 250*750*55 | 7.71 |

P6015 | 600*1500*55 | 36.3 | P2506 | 250*600*55 | 6.39 |

P6012 | 600*1200*55 | 31.7 | P2015 | 200*1500*55 | 11.6 |

P6009 | 600*900*55 | 23.9 | P2012 | 200*1200*55 | 9.4 |

P6007 | 600*750*55 | 18.55 | P2009 | 200*900*55 | 7.1 |

P6006 | 600*600*55 | 16.25 | P2007 | 200*750*55 | 5.9 |

P5018 | 500*1800*55 | 36.27 | P2006 | 200*600*55 | 6.39 |

P5015 | 500*1500*55 | 30.15 | P2004 | 200*450*55 | 3.64 |

P5012 | 500*1200*55 | 25.55 | P1515 | 150*1500*55 | 9.5 |

P5009 | 500*900*55 | 20.38 | P1506 | 150*600*55 | 4 |

P5007 | 500*750*55 | 15.48 | P1504 | 150*450*55 | 2.98 |

P5006 | 500*600*55 | 13.58 | P1015 | 100*1500*55 | 7.5 |

Code | Size (mm) | Weight (KG) |

P1012 | 100*1200*55 | 6.9 |

P1009 | 100*900*55 | 4.6 |

P1007 | 100*750*55 | 3.8 |

P1006 | 100*600*55 | 3.1 |

P1004 | 100*450*55 | 2.33 |

E1515 | 150*150*1500 | 15.2 |

E1512 | 150*150*1200 | 12.26 |

E1509 | 150*150*900 | 9.34 |

E1507 | 150*150*750 | 7.77 |

E1506 | 150*150*600 | 6.46 |

E1504 | 150*150*450 | 4.87 |

E1015 | 100*150*1500 | 13.13 |

E1012 | 100*150*1200 | 10.61 |

E1009 | 100*150*900 | 8.07 |

E1006 | 100*150*600 | 5.44 |

Y1018 | 100*150*1800 | 14.56 |

Y1015 | 100*150*1500 | 12.29 |

Y1012 | 100*150*1200 | 9.72 |

Y1009 | 100*150*900 | 7.46 |

Y1007 | 100*150*700 | 6.19 |

Y1006 | 100*150*600 | 5.19 |

Y1004 | 100*150*450 | 3.92 |

J0018 | 50*50*1800 | 4.34 |

J0015 | 50*50*1500 | 3.7 |

J0012 | 50*50*1200 | 2.94 |

J0009 | 50*50*900 | 2.3 |

J0007 | 50*50*750 | 1.9 |

J0006 | 50*50*600 | 1.5 |

J0004 | 50*50*450 | 1.13 |

FAQ :

1. Who are we ?

We , CNBM , are a State-Owned Enterprise which established in 1984 , have 32 years experience ,enjoy high reputation .

2. Our Advantage :

Customized products , we have our own R&D department , we can design the drawing and suggest the suitable solution for your project .

3. Our after-Sales Service :

The international Sales Manager and Engineer can go to your job site for work direction and help you deal with your project .

Factory Photos :

- Q:Can steel formwork be used for pier caps?

- Yes, steel formwork can be used for pier caps. Steel formwork offers several advantages such as high strength, durability, and reusability. It can provide a smooth and precise finish to the pier caps, ensuring a high-quality end result. Additionally, steel formwork can be easily assembled and disassembled, allowing for efficient construction processes. Therefore, steel formwork is a suitable choice for constructing pier caps, as it can provide the necessary support and structural integrity required for this application.

- Q:How does steel formwork handle concrete shrinkage and cracking?

- Steel formwork is a versatile and durable option for handling concrete shrinkage and cracking. It is designed to provide support and stability during the pouring and curing process, and its rigid structure helps to minimize the effects of shrinkage and cracking. One of the key advantages of using steel formwork is its ability to withstand the pressure exerted by the concrete as it shrinks. Steel is a strong and resilient material that can resist the forces generated by the drying and hardening of the concrete. This helps to prevent the formwork from deforming or collapsing under the weight of the shrinking concrete, ensuring that the structure remains intact. In addition, steel formwork is often equipped with expansion joints or other flexible elements that can accommodate the movement caused by shrinkage and cracking. These joints allow the formwork to expand and contract with the concrete, reducing the stress on the structure and minimizing the risk of cracks forming. Furthermore, steel formwork can be easily reinforced or supplemented with additional support elements, such as braces or tie rods, to further enhance its ability to handle concrete shrinkage and cracking. These reinforcements help to distribute the forces exerted by the shrinking concrete more evenly across the formwork, reducing the likelihood of localized cracking or structural failure. Overall, steel formwork provides a robust and reliable solution for managing concrete shrinkage and cracking. Its strength, flexibility, and ability to be reinforced make it an ideal choice for construction projects where minimizing the impact of these issues is crucial.

- Q:How does steel formwork contribute to the overall safety of the construction process?

- There are several ways in which steel formwork enhances the safety of the construction process. Firstly, its strength and durability allow it to withstand the weight and pressure exerted during construction, reducing the possibility of formwork failure and subsequent accidents or injuries. Moreover, steel formwork is specifically designed to create a stable and secure structure for pouring concrete. Its precise alignment and tight joints prevent any leakage or seepage of concrete, thus minimizing the chances of structural instability or collapse. This ensures the safety of workers and the overall integrity of the building under construction. Furthermore, steel formwork exhibits high resistance to fire and high temperatures. In the unfortunate event of a fire on the construction site, it acts as a fire-resistant barrier, protecting workers and preventing the spread of fire to other areas. Consequently, the risk of fire-related accidents or injuries is greatly reduced, enhancing the overall safety of the construction process. In addition, steel formwork is designed to be reusable, allowing it to be utilized for multiple construction projects. This not only reduces formwork costs but also minimizes waste and environmental impact. By opting for steel formwork, construction companies can promote sustainability and create a safer construction environment by minimizing the need for constant formwork replacement. In conclusion, steel formwork makes a significant contribution to the overall safety of the construction process by providing strength, durability, stability, and fire resistance. Its precise alignment and tight joints ensure the integrity of the structure being built, diminishing the risk of accidents or collapse. Additionally, its reusability supports sustainability efforts and waste reduction. Overall, steel formwork plays a vital role in establishing a safe and secure construction site.

- Q:What are the different types of steel formwork available?

- In the construction industry, there exists a variety of steel formwork options, each possessing its own distinctive characteristics and benefits. Some of the most prevalent variations include: 1. Modular steel formwork: This formwork type comprises pre-made steel panels that can be effortlessly assembled and disassembled. It boasts customization capabilities and can accommodate concrete structures of diverse shapes and sizes. 2. Tunnel formwork: Specifically designed for tunnel and underground structure construction, this formwork variant is forged from steel plates. Its robust construction enables it to withstand high pressure and deliver a polished finish to the concrete. 3. Climbing formwork: Tailored for tall structures such as skyscrapers, climbing formwork is engineered to be lifted and moved vertically as construction progresses. This type of formwork ensures both safety and efficiency during the construction of multi-story buildings. 4. Steel soldier formwork: A versatile and cost-effective option often employed for walls and columns, steel soldier formwork is constructed using steel beams and soldiers. It can be easily adjusted to accommodate different heights and widths. 5. Steel frame formwork: Comprised of steel frames with attached plywood or metal panels, this lightweight formwork type is easy to handle and guarantees a smooth concrete finish. 6. Steel table formwork: Ideal for large horizontal slabs, steel table formwork utilizes steel tables supported by props or scaffolding. Its quick assembly and dismantling make it perfect for projects with tight timelines. These examples represent only a fraction of the available steel formwork options. The selection of formwork depends on project-specific requirements, including the structure type, load-bearing capacity, and desired finish.

- Q:How does steel formwork affect the overall vibration resistance of the structure?

- A structure can greatly improve its vibration resistance through the utilization of steel formwork. Steel, as a formwork material, offers several advantages that contribute to enhanced structural stability and reduced vibrations. To begin with, steel formwork is renowned for its exceptional strength and rigidity. It provides a sturdy framework that can withstand the dynamic forces and loads experienced by a structure throughout its lifespan. This increased strength aids in the minimization of potential vibrations caused by external factors such as wind, earthquakes, or nearby heavy machinery operations. Additionally, steel formwork enables a precise and accurate construction process, ensuring a tight fit and proper alignment of structural elements. This precise assembly reduces the presence of any gaps or unevenness, which can amplify vibrations. By minimizing these irregularities, the overall vibration resistance of the structure is improved. Moreover, steel formwork exhibits excellent dimensional stability, meaning it remains unchanged in size, shape, or form under varying environmental conditions. This stability guarantees that the structure maintains its integrity and avoids significant deformations that could lead to increased vibrations. Furthermore, steel formwork possesses remarkable resistance to corrosion and deterioration, ensuring its long-term durability. This resistance prevents any weakening of the structure over time, which is crucial for maintaining its vibration resistance. Furthermore, steel formwork offers a higher load-carrying capacity compared to other formwork materials. This increased capability allows for the construction of more robust and resilient structures that can withstand higher dynamic loads without experiencing excessive vibrations. In conclusion, the utilization of steel formwork greatly enhances the overall vibration resistance of a structure by providing strength, rigidity, precision, dimensional stability, corrosion resistance, and increased load-carrying capacity. By incorporating these characteristics, steel formwork helps to minimize vibrations and ensures the structural integrity and safety of the building.

- Q:Can steel formwork be used for complex architectural designs?

- Yes, steel formwork can be used for complex architectural designs. Steel formwork offers high strength and durability, allowing it to withstand the pressure exerted by complex architectural designs. Additionally, its versatility allows for intricate shapes and designs to be achieved with precision and accuracy.

- Q:What are the different components of steel formwork?

- Steel formwork is a type of temporary structure that is used in construction projects to provide support and shape to concrete during the curing process. It consists of several components that work together to create a rigid and durable formwork system. The main components of steel formwork include: 1. Panels: These are the primary components of the formwork system and are usually made of steel or steel-reinforced plywood. They are available in different sizes and shapes and can be easily interconnected to create the desired formwork configuration. 2. Soldiers: These are vertical members that provide support to the formwork panels. They are typically made of steel and are adjustable in height, allowing for flexibility in formwork design. Soldiers are connected to the panels using connecting clamps or pins. 3. Waler Beams: These are horizontal members that help distribute the load evenly across the formwork system. Waler beams are connected to the soldiers using clamps or brackets and are usually made of steel or aluminum. 4. Tie Rods: These are used to hold the formwork panels and soldiers together. They are threaded rods that pass through the panels and are secured with nuts and washers on each side. Tie rods help in maintaining the required spacing between the panels and provide additional strength to the formwork system. 5. Formwork Accessories: These include various components such as clamps, brackets, wedges, and pins that are used to connect and secure the formwork components. They help in maintaining the stability and alignment of the formwork system during concrete pouring and curing. 6. Formwork Joints: These are specially designed connectors that allow for easy assembly and disassembly of the formwork system. They ensure proper alignment and tightness of the formwork components, preventing leakage of concrete and maintaining the desired shape. 7. Formwork Supports: These are used to provide additional support to the formwork system, especially for larger and complex structures. Formwork supports can be in the form of props, scaffolding, or specialized shoring systems, depending on the specific requirements of the project. Overall, these components work together to create a strong and stable formwork system that can withstand the pressure and weight of the concrete during the construction process. Steel formwork is preferred for its durability, reusability, and ease of assembly and disassembly, making it a popular choice in modern construction projects.

- Q:How does steel formwork affect the overall construction site organization?

- Steel formwork can have a significant impact on the overall organization of a construction site. Firstly, steel formwork is known for its durability and reusability, which means it can be used multiple times for different projects. This allows for better planning and scheduling of construction activities, as the availability of formwork is more predictable and reliable. Additionally, steel formwork is known for its precision and accuracy, which leads to better quality construction. This can result in fewer reworks and delays, as the formwork ensures that concrete is poured in the right place and to the correct dimensions. Consequently, the overall construction process becomes more efficient, allowing for better organization and coordination of various trades and activities on the site. Steel formwork also offers flexibility in design and construction. It can be easily adjusted and modified to accommodate changes in the project, such as alterations in the shape or size of concrete elements. This adaptability reduces the need for additional materials and resources, which can streamline the organization of the construction site and minimize waste. Furthermore, steel formwork is known for its strength and stability. This allows for taller and larger concrete structures to be constructed, which can have implications for the overall layout and organization of the site. For example, it may require additional crane or lifting equipment to handle the heavier and larger formwork components. This necessitates careful planning and coordination to ensure that the site is properly organized to accommodate these requirements. In summary, steel formwork positively impacts the overall organization of a construction site by providing durability, precision, flexibility, and strength. These attributes contribute to better planning, scheduling, and coordination of construction activities, resulting in improved efficiency, quality, and adaptability.

- Q:How does steel formwork contribute to the overall aesthetics of the structure?

- Steel formwork contributes to the overall aesthetics of a structure by providing a smooth and clean finish to the concrete surfaces. Its precise and rigid construction ensures that the concrete is accurately formed, resulting in sharp corners, straight lines, and a consistent appearance. Steel formwork also allows for the creation of intricate designs and unique architectural features, enhancing the visual appeal of the structure. Furthermore, steel formwork can be reused multiple times, reducing waste and promoting sustainable construction practices, which also adds to the overall aesthetic value of the project.

- Q:How does steel formwork affect the construction schedule?

- The construction schedule can be significantly impacted by steel formwork. One of the main benefits of using steel formwork is its ability to provide a high level of stability and strength, enabling faster construction processes. This results in reduced overall construction time compared to traditional formwork methods. Moreover, steel formwork is highly durable and can be used multiple times, making it suitable for future projects. This reduces the time and cost associated with acquiring and assembling new formwork for each project, further enhancing the efficiency of the construction schedule. In addition, steel formwork allows for precise and accurate construction, resulting in a higher quality finished product. This minimizes the need for rework and corrections, ultimately saving time and ensuring that the project stays on schedule. Furthermore, steel formwork is known for its flexibility and adaptability. It can be easily adjusted and modified to accommodate design or construction changes. This promotes a smoother workflow and minimizes delays that may arise from design alterations. However, it is important to note that the initial setup and installation of steel formwork may require more time and resources compared to other formwork systems. The design and fabrication process for steel formwork can be more complex, necessitating careful planning and coordination. Therefore, it is crucial to consider these factors during the project planning phase to ensure that the construction schedule is not negatively affected. Overall, steel formwork can significantly expedite the construction schedule by offering strength, durability, precision, and adaptability. However, it is essential to thoroughly evaluate project requirements and available resources to optimize the use of steel formwork and minimize potential disruptions to the construction schedule.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Formwork for Skyspare Export to Indonesia

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords