STAINLESS STEEL PIPE CHEAP and GOOD QUALITY from CHINA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

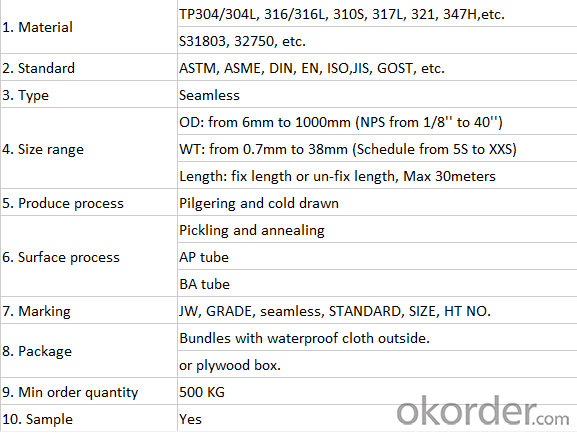

1,the breif description of the cheap and good quality stainless steel pipe

2,our advantage and specifications

1. Our company has been dedicated to producing stainless steel seamless pipe since 2003, owning complete producing technology and abundant managing experience.

2. The raw material such as mother tube, round bar we use is from Chinese biggest and well-known steel mill: Walsin Steel and Yongxing Steel.

3. We have advanced NDT equipments for the tests such as Eddy Current test, Ultrasonic test, Hydraulic test and so on.

4. We have ISO 9001 and PED certificate, and the Third Party Inspection Certificates such as TUV, BV, Lloyd’s, SGS, etc, also can be provided according to customers’ requirements,

5. Wooden case package which is strong and suitable for sea transportation is our main method to pack the pipes. And the economical packing method such as packed in bundles is also welcomed by some customers.

6. The tolerance control we use is D4/T4 (+/-0.1mm) on both inside and outside Diameter and Wall Thickness, which is much higher than international standard ASTM, DIN.

7. The surface condition is one of our main advantages: in order to meet different requirements for surface condition, we have annealing and pickling surface, bright annealing surface, OD polished surface, OD & ID polished surface etc.

8. In order to keep the inside surface of pipe clean and make it free from deburring, our company develops the unique and special technology --- Sponge Washing with high pressure.

9. We have complete after-sale service to deal with the problems in time.

3,Stainless steel maintenance:

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

4,FAQ

1. Q: What are your advantageous Products?

A: We specialized in 400 series cold rolled stainless steel coils and plates. Our main products are 430, 410S and 409L.

We also supply stainless steel strips and strips in coil as requested.

2. Q: Can you make DDQ ( Deep Drawing Quality)?

A: Yes, we can. Our material can be used for stainless steel pots, stainless steel sinks, stainless steel bowls etc. U can tell us your usage, and we will adjust the mechanical propertise to meet your requirement.

- Q:Can stainless steel pipes be used in drinking water systems?

- Yes, stainless steel pipes can be used in drinking water systems. Stainless steel is a highly durable and corrosion-resistant material that can withstand the harsh elements present in water systems. It does not leach any harmful substances into the water, making it a safe choice for drinking water applications. Additionally, stainless steel pipes are easy to clean and maintain, further ensuring the quality and safety of the drinking water.

- Q:What is the tensile strength of stainless steel pipes?

- The tensile strength of stainless steel pipes can vary depending on the specific grade and manufacturing process, but it typically ranges from 515 to 827 megapascals (MPa) or 74,800 to 119,900 pounds per square inch (psi).

- Q:Can stainless steel pipes be used for sewage pumping stations?

- Yes, stainless steel pipes can be used for sewage pumping stations. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions and chemicals present in sewage. Additionally, stainless steel pipes offer excellent durability and longevity, making them suitable for use in sewage pumping stations.

- Q:What are the temperature limits for stainless steel pipes?

- The temperature limits for stainless steel pipes can vary depending on the grade of stainless steel used. Generally, stainless steel pipes can withstand temperatures ranging from -150°C to 1100°C (-238°F to 2012°F). However, it is crucial to consider factors such as the specific stainless steel grade, the application, and any potential thermal expansion or contraction issues when determining the temperature limits for a particular stainless steel pipe.

- Q:What are stainless steel pipes used for?

- Stainless steel pipes are widely used in various industries for their exceptional durability, corrosion resistance, and high strength. They find extensive applications in plumbing systems, oil and gas industries, chemical processing plants, food and beverage processing, pharmaceutical industries, and automotive manufacturing, among others. In plumbing systems, stainless steel pipes are favored for their ability to withstand high pressure and temperature, making them suitable for transporting water, gas, and other fluids. They are also commonly used in sewage and drainage systems due to their resistance to corrosion and chemical substances. In the oil and gas industries, stainless steel pipes are used for transporting petroleum products, natural gas, and other fluids under high pressure and extreme temperatures. Their corrosion resistance properties make them indispensable in offshore and onshore drilling operations, refineries, and petrochemical plants, ensuring the safe and efficient transportation of these substances. Chemical processing plants rely on stainless steel pipes for their resistance to chemical reactions and high temperatures. They are used to transport various corrosive chemicals and gases without the risk of contamination or leakage. Additionally, stainless steel pipes are utilized in heat exchangers, reactors, and other equipment that require corrosion-resistant materials. The food and beverage industry also heavily relies on stainless steel pipes due to their hygiene and sanitary properties. They are used for conveying various food products, such as milk, wine, beer, and other liquids, without altering their taste or quality. Stainless steel pipes are easy to clean, maintain, and sterilize, making them ideal for this industry. In the pharmaceutical sector, stainless steel pipes play a crucial role in conveying various drugs, chemicals, and sterile fluids. They meet the stringent requirements of the industry by ensuring product purity, preventing contamination, and offering resistance to corrosion and temperature extremes. Moreover, stainless steel pipes are utilized in automotive manufacturing for their structural strength and resistance to heat and corrosion. They are used in exhaust systems, fuel lines, and other components where durability and resistance to extreme conditions are necessary. Overall, stainless steel pipes are versatile and essential in numerous industries, providing the perfect combination of strength, durability, and corrosion resistance needed for a wide range of applications.

- Q:What is the difference between 304J1 and 316J1 stainless steel pipes?

- The chemical composition and presence of certain elements distinguish 304J1 stainless steel pipes from 316J1 stainless steel pipes. 304J1 stainless steel is a variation of the well-known 304 stainless steel grade. It possesses a lower carbon content than regular 304, granting it increased resistance to intergranular corrosion. This is achieved by incorporating a small amount of titanium into the composition. 304J1 stainless steel pipes are suitable for a wide range of applications, including plumbing, food processing, and architectural uses. On the other hand, 316J1 stainless steel is a variation of the 316 stainless steel grade. It shares similarities with regular 316 stainless steel in terms of corrosion resistance, but it has a lower carbon content, similar to 304J1. Additionally, 316J1 contains a small amount of molybdenum, which enhances its resistance to pitting and crevice corrosion in chloride environments. As a result, 316J1 stainless steel pipes are commonly employed in marine environments, chemical processing plants, and other scenarios where exposure to corrosive substances is anticipated. To summarize, the primary disparity between 304J1 and 316J1 stainless steel pipes lies in their chemical composition, with the latter offering superior corrosion resistance in more aggressive environments. The selection between the two would hinge on the specific application and the desired level of corrosion resistance.

- Q:Can stainless steel pipes be used for underground drainage systems?

- Indeed, underground drainage systems can utilize stainless steel pipes. Stainless steel proves to be a robust and corrosion-resistant substance capable of enduring the harsh conditions commonly encountered beneath the surface, encompassing moisture, soil chemicals, and fluctuating temperatures. Furthermore, stainless steel pipes exhibit resistance to rust, a prevalent issue faced by alternative pipe materials. Moreover, their extended lifespan and minimal maintenance demands render stainless steel pipes a fitting selection for underground drainage systems.

- Q:What is the difference between 17-4 and 316 stainless steel pipes?

- The composition and properties of 17-4 and 316 stainless steel pipes differ significantly. 17-4 stainless steel, also called SAE type 630, is a precipitation-hardening stainless steel with approximately 17% chromium and 4% nickel. It also contains small amounts of copper, niobium, and tantalum. These elements allow 17-4 stainless steel to undergo a heat treatment process called precipitation hardening, which enhances its strength and hardness. This makes it ideal for applications requiring high strength and good corrosion resistance, such as aerospace and defense industries. However, it may not have the best resistance to certain corrosive environments compared to other stainless steels. In contrast, 316 stainless steel is an austenitic stainless steel with around 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. This composition offers excellent corrosion resistance, particularly in chloride-containing environments like marine or coastal areas. 316 stainless steel is also known for its weldability and formability, making it a popular choice in industries such as food processing, pharmaceuticals, and chemical processing. In conclusion, the primary discrepancy between 17-4 and 316 stainless steel pipes lies in their composition and properties. 17-4 stainless steel provides greater strength and hardness through precipitation hardening, whereas 316 stainless steel offers superior corrosion resistance, particularly in chloride-containing environments. The selection between the two depends on the specific requirements of the application, considering factors like strength, corrosion resistance, and more.

- Q:Can stainless steel pipes be used for gas distribution?

- Yes, stainless steel pipes can be used for gas distribution. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for a wide range of applications, including gas distribution systems. It provides excellent resistance to the corrosive effects of gases and moisture, ensuring the integrity and safety of the gas distribution network. Additionally, stainless steel pipes have high tensile strength, which allows them to withstand high pressure and temperature conditions commonly encountered in gas distribution. Moreover, stainless steel is non-reactive and does not release harmful substances into the gas stream, making it a reliable choice for transporting gases. Overall, stainless steel pipes are a preferred choice for gas distribution due to their durability, corrosion resistance, and high safety standards.

- Q:How do stainless steel pipes compare to polyethylene pipes?

- Stainless steel pipes and polyethylene pipes are two commonly used materials for various plumbing and industrial applications. While both materials have their advantages and disadvantages, they differ in terms of strength, durability, cost, and application suitability. Stainless steel pipes are known for their exceptional strength and durability. They can withstand high pressure and temperature, making them suitable for applications in industries such as oil and gas, chemical processing, and water distribution. Stainless steel pipes are also resistant to corrosion, rust, and fire, making them a reliable choice for long-term use. However, they tend to be heavier and more expensive than polyethylene pipes. On the other hand, polyethylene pipes are lightweight, flexible, and relatively inexpensive compared to stainless steel pipes. They are commonly used in applications such as irrigation, water supply, and drainage systems. Polyethylene pipes are resistant to chemicals, impact, and abrasion, making them suitable for underground installation. However, they may not be as durable as stainless steel pipes and may require more frequent replacements or repairs in some cases. In terms of installation and maintenance, stainless steel pipes are generally more demanding as they require specialized tools and skills. Polyethylene pipes, on the other hand, are easier to install and maintain due to their flexibility and simple jointing techniques. Ultimately, the choice between stainless steel pipes and polyethylene pipes depends on the specific requirements of the application. If strength, durability, and resistance to extreme conditions are crucial, stainless steel pipes are the preferred option. For less demanding applications that require cost-effectiveness, flexibility, and ease of installation, polyethylene pipes may be more suitable. It is important to consider factors such as budget, operating conditions, lifespan, and maintenance requirements when comparing these two pipe materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

STAINLESS STEEL PIPE CHEAP and GOOD QUALITY from CHINA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords