Square Steel Billets Hot Sale Q235B/5SP in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 800 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Description of steel billet:

Our company is recognized by ISO9001:2008

1. hot rolled wire rod

2. material: Q195-235

Festures of steel billet:

1. Drawn wire specialist, your wire rod solution

2. ISO9001 Certified Mill &SGS

3. Feature: machinability, high hardness, toughness, corrosion resistant

Specifications of steel billet:

Type | Steel billet / Square steel/ Steel square bar |

Standard grade | 3SP/PS, 5SP/PS, Q195, Q235, Q255, Q275, 20MnSi etc. |

MOQ | 1000 MT |

Technique | Hot rolled |

Size | 50*50mm ~ 160*160mm |

Length | 3~12m |

Packing | Loose packing, in bundle |

Payment terms | T/T, L/C at sight, Usance L/C |

Trade terms | EXW, FOB, CFR, CIF |

Trans terms | FIO, FILO, FLT |

Inspection | Third party inspection accepted |

Delivery time | 15-30 days, according to the quantity |

Applications | carbon structural steel, wire rod, rod, deformed bars, profile steel, machine parts, and steel moulds etc . |

Note | Customized service is available (for sizes,length and chemical components etc.). |

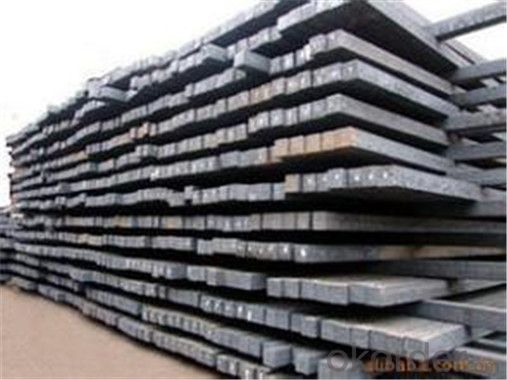

Images of steel billet:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q:How is the dimensional accuracy of steel wire rod measured?

- The dimensional accuracy of steel wire rod is typically measured using various techniques and tools to ensure that the dimensions of the rod meet the required specifications. Some commonly used methods to measure the dimensional accuracy of steel wire rod include: 1. Calipers: Calipers are used to measure the diameter of the steel wire rod. They can be either manual or digital, and they provide accurate readings by tightly gripping the rod and measuring its diameter. 2. Micrometers: Micrometers are precise measuring tools used to measure the diameter of the steel wire rod. They provide highly accurate readings by using a calibrated screw mechanism to measure the dimensions. 3. Optical measurement systems: Optical measurement systems use advanced technology, such as lasers or cameras, to measure the dimensions of the steel wire rod. These systems provide accurate and quick measurements by capturing multiple data points and analyzing them to determine the dimensional accuracy. 4. Ultrasonic measurement: Ultrasonic measurement techniques involve emitting ultrasonic waves into the steel wire rod and analyzing the reflected waves to determine its dimensions. This method is especially useful for measuring the thickness and cross-sectional dimensions of the rod. 5. Automated measurement systems: Automated measurement systems utilize specialized equipment and software to measure the dimensional accuracy of steel wire rods. These systems can provide accurate and repeatable measurements by employing robotics, sensors, and image processing algorithms. It is important to note that the specific measurement technique used may vary depending on the required dimensions, tolerances, and the capabilities of the manufacturer or testing facility.

- Q:What are the different grades of steel wire rods?

- Steel wire rods come in various grades, each having its own distinct properties and uses. Some commonly used grades include: 1. Grade 1006 - 1018: These are low carbon steel wire rods, known for their high ductility and ease of shaping. They find applications in wire mesh, fencing, nails, and general-purpose wire products. 2. Grade 1030 - 1050: These medium carbon steel wire rods have a higher carbon content, which imparts increased strength and hardness. They are commonly employed in the manufacturing of springs, automotive parts, and machinery components. 3. Grade 1060 - 1095: High carbon steel wire rods, with the highest carbon content, possess exceptional strength and toughness. They are extensively used in the production of high-strength wires, piano wires, and industrial springs. 4. Alloy steel wire rods: These rods are made by incorporating various alloying elements like chromium, nickel, and molybdenum, which enhance their mechanical properties. They cater to specialized applications that demand specific attributes such as corrosion resistance, heat resistance, or high tensile strength. 5. Stainless steel wire rods: Made from stainless steel containing a minimum of 10.5% chromium, these rods provide excellent corrosion resistance. They are frequently employed in applications like wire rope, fishing nets, and surgical instruments. Each grade of steel wire rod is meticulously engineered to meet precise requirements in terms of strength, ductility, hardness, and other mechanical properties. The choice of grade depends on the intended application and the desired performance characteristics.

- Q:What is the average price of steel wire rod?

- The average price of steel wire rod varies depending on factors such as the quality, size, and market conditions. It is recommended to consult with suppliers or refer to industry reports to get the most accurate and up-to-date information on the average price.

- Q:What are the major players in the global steel wire rod market?

- The major players in the global steel wire rod market include ArcelorMittal, Nippon Steel Corporation, Tata Steel Ltd., POSCO, JFE Steel Corporation, Nucor Corporation, Steel Authority of India Limited (SAIL), EVRAZ plc, Gerdau S.A., and Sohar Steel LLC. These companies are leading manufacturers and suppliers of steel wire rod, which is widely used in various industries such as construction, automotive, and manufacturing. They have a strong presence in key markets across the globe and have a significant share in the global steel wire rod market. These major players often invest in research and development to develop innovative products and improve their production processes, ensuring their competitiveness in the market. They also focus on strategic partnerships, acquisitions, and expansions to expand their market reach and strengthen their position in the global steel wire rod market.

- Q:How is steel wire rod used in the manufacturing of wire forms for fishing nets?

- The manufacturing of wire forms for fishing nets relies heavily on steel wire rod. This essential component undergoes a series of steps to be transformed into a usable wire form. Cleaning, annealing, and drawing processes are employed to achieve the desired diameter and tensile strength. These procedures are crucial in ensuring that the wire possesses the necessary strength and flexibility to withstand the tension and stress it will encounter when used in fishing nets. Once the wire rod has been converted into wire, it is then utilized to fashion the various wire forms needed for fishing nets. These wire forms, including hoops, rings, loops, and connectors, are vital in constructing a functional fishing net. Specialized machinery and techniques, such as bending, cutting, and welding, are employed to create these wire forms according to the specific design requirements. The wire forms are then assembled together to form the structure of the net. The utilization of steel wire rod in the manufacturing of wire forms for fishing nets offers numerous advantages. Steel is renowned for its high strength and durability, making it an ideal material for withstanding the harsh conditions and constant tension experienced by fishing nets. Moreover, steel wire rod is resistant to corrosion, ensuring that the wire forms will have a long lifespan even when exposed to water and other environmental factors. In conclusion, steel wire rod plays a vital role in the manufacturing of wire forms for fishing nets. It serves as the raw material from which the wire forms are created, providing the necessary strength, flexibility, and durability required for a functional fishing net.

- Q:How are steel wire rods used in the production of wire ropes for cranes?

- Steel wire rods are used as the basic material in the production of wire ropes for cranes. These rods are first drawn through a series of dies to reduce their diameter and increase their length. Then, multiple wire rods are twisted and braided together to form a strong and flexible wire rope. This wire rope is then used in cranes for lifting and hoisting heavy loads due to its high strength and durability.

- Q:What are the safety requirements for steel wire rod used in mining wire ropes?

- The safety requirements for steel wire rod used in mining wire ropes include high tensile strength, resistance to corrosion and abrasion, proper heat treatment to ensure ductility and toughness, reliable breaking strength, stringent quality control measures, and compliance with industry standards such as ISO and ASTM. Regular inspections, testing, and maintenance are also essential to ensure the safe and reliable operation of mining wire ropes.

- Q:What are the main factors influencing the choice of steel wire rod order replacement policy?

- Several factors play a significant role in the decision-making process when it comes to choosing a replacement policy for steel wire rod orders. These factors include market demand, production capacity, inventory management, and cost considerations. Market demand is a crucial factor that determines the replacement policy for steel wire rod orders. The level of customer demand influences the frequency and volume of orders required. If there is high demand and a rapid turnover of inventory, a more frequent replacement policy may be necessary to meet customer needs. Production capacity is another essential factor to consider. The ability of the steel wire rod manufacturer to produce and deliver orders on time affects the replacement policy. If production capacity is limited, more frequent orders may be needed to avoid stockouts and ensure a steady supply. Effective inventory management is also critical in determining the replacement policy. It involves maintaining an optimal inventory level to avoid excess or shortage. By analyzing historical demand patterns and lead times, companies can develop inventory management strategies that minimize stockouts while reducing carrying costs. The replacement policy must align with these objectives. Cost considerations also play a significant role. Companies need to evaluate the costs associated with frequent orders, such as administrative expenses and transportation costs, against the benefits of maintaining a steady supply. Additionally, the cost of holding excess inventory and the risks of obsolescence or deterioration should be taken into account. A comprehensive cost-benefit analysis should determine the most appropriate replacement policy. In conclusion, market demand, production capacity, inventory management, and cost considerations are the main factors influencing the choice of steel wire rod order replacement policy. By carefully considering these factors, companies can develop a policy that ensures a consistent and sufficient supply of steel wire rods while optimizing operational efficiency and cost-effectiveness.

- Q:What are the environmental considerations associated with steel wire rod production?

- The environmental considerations associated with steel wire rod production include energy consumption, greenhouse gas emissions, water usage, waste generation, and potential impact on surrounding ecosystems. The production process involves high energy requirements, mainly from electricity and fuel consumption, contributing to carbon dioxide emissions. Water is often used for cooling and cleaning purposes, leading to water scarcity concerns and potential contamination. Waste generation includes byproducts like slag and scale, which require proper disposal or recycling to minimize environmental impact. Additionally, the extraction of raw materials, such as iron ore and coal, can lead to habitat destruction and biodiversity loss. However, advancements in technology and sustainable practices are being implemented to reduce these environmental impacts and promote more eco-friendly steel production.

- Q:What are the different surface treatment processes used for steel wire rod?

- Some of the different surface treatment processes used for steel wire rod include hot-dip galvanizing, electro-galvanizing, phosphating, and coating with oil or polymer-based materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Square Steel Billets Hot Sale Q235B/5SP in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 800 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords