PP/ HDPE One-Way Plastic Geogrid Products

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

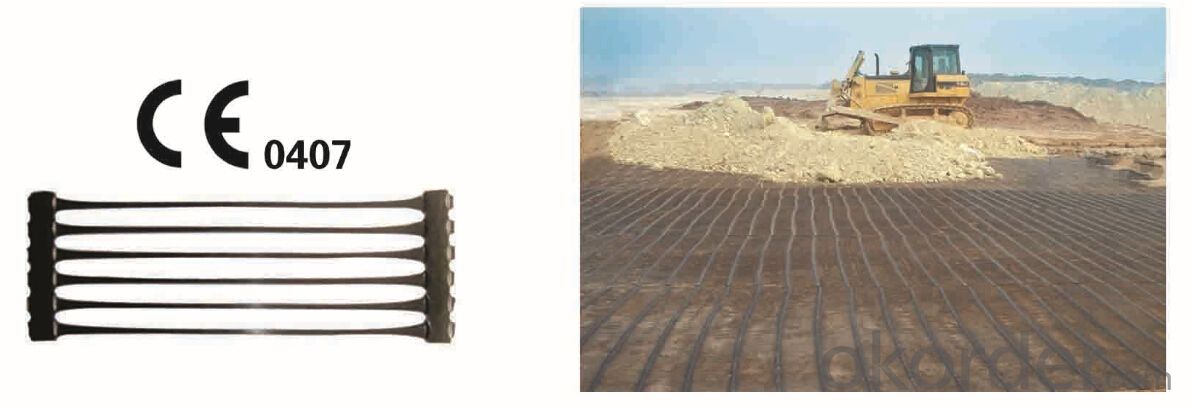

One-Way Plastic Geogrid Products

Products overview:

Unidirectional geogrid is made of polymer by extrusion pressure into sheet rules of mesh again, then the longitudinal tensile and into. The directional linear polymer into state and in the process of uniform distribution, long oval mesh nodes with high intensity is the structure integrity. This kind of structure has a very high tensile strength and tensile modulus, especially my company this kind of product is more than the international level of high early (elongation at 2% to 2%), tensile strength and tensile modulus. To the soil provides ideal assumption of the force and the spread of the chain system, the product tensile strength (> 150 mpa), adapt to all kinds of soil, is currently widely used reinforcement reinforcement material.

Product features:

1, strengthen roadbed, can effectively allocate diffusion load, improve the stability and bearing capacity of subgrade, prolong service life.

2, can withstand greater alternating load;

3, prevent subgrade material loss caused by the embankment, cracking;

4, make the file after the wall of the filled soil bearing capacity increase, reduce the pressure of the retaining wall, save costs and prolong service life, and reduce maintenance costs;

5, spray anchor concrete construction method for slope maintenance, not only can save 30% - 50% of the investment, but also can shorten the time limit for a project more than double;

6, adding geogrid in highway roadbed and road surface, reduces the deflection, reduce furrow, delay cracking 3 to 9 times, structure layer thickness can be reduced by 36%;

7, used in a variety of soil, no need different materials, save work time;

8, easy construction, can greatly reduce the construction cost.

Product application:

1, mainly used for retaining wall, abutment, steep slope engineering, etc.;

2, retaining wall and the abutment belongs to the mechanical structure, all bear the external loads, the active earth pressure, the upper structure of the load, temperature stress, such as reinforced material under great tension for a long time, and again and again under the action of dynamic load, the molecular structure of the material to produce fatigue, its performance attenuation, accelerate the ageing of the grille, to avoid structure due to the creep in reinforcement material and produce large deformation, should choose to unidirectional geogrid of high-density polyethylene as raw material.

Product specifications:

TGDG35 TGDG50 TGDG80 TGDG110 TGDG120

- Q:Glass steel grille is how to produce

- Production process of FRP grid:Preparation of mold - Preparation of mixed resin - glass fiber yarn - (or at the same time) pouring resin and exhaust bubble - mold heating, product curing - mold - finishing - Inspection packaging.

- Q:Glass fiber mesh cloth is mainly used in what place

- Wall materials (such as glass fiber wall cloth, GRC wall panels, EPS internal and external wall insulation board, gypsum board, etc.)

- Q:Are geogrids suitable for reinforcing bridge abutment backfills?

- Yes, geogrids are suitable for reinforcing bridge abutment backfills. Geogrids are commonly used in civil engineering and construction projects to enhance the stability and strength of soil structures. They can effectively distribute loads, reduce soil settlement, and improve overall performance of backfill materials. Therefore, geogrids are a reliable option for reinforcing bridge abutment backfills.

- Q:Can geogrids be used in construction of temporary access roads over soft ground?

- Yes, geogrids can be used in the construction of temporary access roads over soft ground. Geogrids provide reinforcement and stabilization to the soil, distributing the load and preventing excessive settlement and rutting. This makes them an effective solution for creating temporary access roads that can withstand heavy traffic and adverse ground conditions.

- Q:How do geogrids improve the performance of geotextile-reinforced slopes?

- Geogrids improve the performance of geotextile-reinforced slopes by providing additional tensile strength and stability. They act as a reinforcement material, increasing the load-bearing capacity and preventing soil erosion. Geogrids also enhance the overall slope stability by distributing stresses and reducing lateral movement of soil particles.

- Q:What are the technical parameters and testing standards of the tensile creep testing machine

- Technical parameters: 1 180KN; the maximum load: 2 load accuracy: less than 1%; 3 fixture width 50mm and 200mm optional; 4 effective creep space

- Q:Are there any specific maintenance requirements for geogrids?

- Yes, geogrids have specific maintenance requirements. They should be inspected regularly for any signs of damage or deterioration, such as tears, fraying, or disintegration. If any issues are found, appropriate repairs or replacements should be made promptly to ensure the geogrid's effectiveness. Additionally, geogrids should be kept clean and clear of any debris or vegetation that could impact their performance.

- Q:Are geogrids resistant to UV degradation?

- Yes, geogrids are generally resistant to UV degradation. They are designed to withstand prolonged exposure to sunlight without significant degradation or loss of strength.

- Q:Polypropylene geogrid and plastic geogrid

- Not the same, plastic geogrid points; polyethylene, polypropylene two!

- Q:How do geogrids help in reducing the risk of settlement of structures?

- Geogrids help in reducing the risk of settlement of structures by providing reinforcement to the soil or fill material beneath the structure. They create a stronger and more stable base, distributing the load evenly and preventing excessive settlement. This helps to maintain the integrity of the structure and reduce the potential for damage or failure due to settlement.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP/ HDPE One-Way Plastic Geogrid Products

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords