Polycrystalline Solar Cells A GRADE Wholesale High Efficiency with Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction of Solar Cells

A solar cell, is an electrical device that converts the energy of light directly into electricity by the photovoltaic effect, which is a physical and chemical phenomenon. It is a form of photoelectric cell, defined as a device whose electrical characteristics, such as current, voltage, or resistance, vary when exposed to light. Solar cells are the building blocks of photovoltaic modules, otherwise known as solar panels.

Polycrystalline Silicon Solar Cells Advantage:

• High efficiency and stable performance in photovoltaic conversion.

• Advanced diffusion technique ensuring the homogeneity of energy conversion efficiency of the cell.

• Advanced PECVD film forming, providing a dark blue silicon nitride anti-reflection film of homogenous color and attractive appearance.

• High quality metal paste for back surface and electrode, ensuring good conductivity, high pulling strength and ease of soldering.

• High precision patterning using screen printing, ensuring accurate busbar location for ease with automatic soldering a laser cutting.

Usage of Polycrystalline Solar Cells

Solar cells are often electrically connected and encapsulated as a module. Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting the semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc. Solar cells are also usually connected in series in modules, creating an additive voltage. Connecting cells in parallel will yield a higher current; our solar cells have passed IEC Certification. With high and stable quality, our cells can greatly improve the performance of Solar Modules.

Specification:

Mechanical data and design |

Format - 156 mm × 156 mm ± 0.5 mm |

Thickness- - 200 μm ± 20 μm |

Front (-) - 1.4 mm bus bars (silver),blue anti-reflection coating (silicon nitride) |

Back (+) - 2 mm wide soldering pads (silver) back surface field (aluminium) |

Temperature Coefficient of Cells |

Voc. Temp .coef.%/K -0.364%/K |

Isc . Temp .coef.%/K +0.077%/K |

Pm. Temp. coef.%/K -0.368%/K |

Polycrystalline 156x156mm 3BB | ||||||

EFF Code | EFF. (%) | Pmax(W) | Impp(A) | Vmpp(V) | Isc(A) | Voc(V) |

1760 | 17.60 | 4.28 | 8.060 | 0.531 | 8.610 | 0.633 |

1740 | 17.40 | 4.23 | 8.030 | 0.524 | 8.570 | 0.632 |

1720 | 17.20 | 4.19 | 8.000 | 0.522 | 8.510 | 0.631 |

1700 | 17.00 | 4.14 | 7.850 | 0.521 | 8.490 | 0.622 |

1680 | 16.80 | 4.09 | 7.770 | 0.521 | 8.390 | 0.620 |

1660 | 16.60 | 4.04 | 7.650 | 0.519 | 8.350 | 0.615 |

1640 | 16.40 | 3.99 | 7.580 | 0.516 | 8.290 | 0.615 |

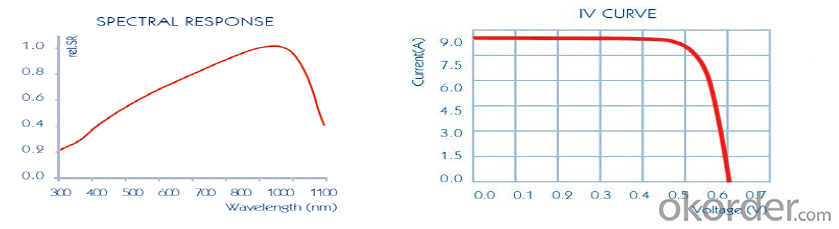

Intensity Dependence |

Intensity [W/m2] Isc× [mA] Voc× [mV] Pmpp |

1000 1.00 1.000 1.00 |

900 0.90 1.000 0.90 |

800 0.80 0.99 0.80 |

500 0.50 0.96 0.49 |

300 0.30 0.93 0.29 |

200 0.20 0.92 0.19 |

IV Curve

Solar Panel Images:

Packaging & Delivery of Polycrystalline Solar Cells

Carton Box Package and Deliver by air. It should be noticed that it should be avoid of water, sunshine and moist.

Faq

We have organized several common questions for our clients,may help you sincerely:

1. What’s price per watt?

A: It’s depends on the quantity, delivery date and payment terms of the order. We can talk further about the detail price issue. Our products is high quality with lower price level.

2. Can you tell me the parameter of your solar cells?

We have different series of cells with different power output, both from c-si to a-si. Please take our specification sheet for your reference.

3. How do you pack your products?

We have rich experience on how to pack the panels to make sure the safety on shipment when it arrives at the destination.

4. Can you do OEM for us?

Yes, we can.

5. How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The perfect time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

Silicon is the ideal material for solar cells, which is the silicon-based solar cells the main reason. But with the development of new materials and related technologies continue to develop, with other material-based solar cells are also showing more and more attractive prospect.

N-type Crystalline Solar Cell

In the bottom plate of the N-type semiconductor solar cell, a greater resistance to impurities, easier to improve the energy conversion efficiency, in theory, the attenuation rate is relatively low, but the process is more complex and costly. Pentavalent element incorporated in pure silicon crystal (such as phosphorus, arsenic, antimony, etc.), so as to replace the position of the crystal lattice of silicon atoms to form a N-type semiconductor.

At present, has reached large-scale production of N-type silicon solar cells, there are three, namely, Japan's Matsushita N-SiHITN type silicon solar cells, the United States SunpowerIBC structure N-type silicon solar cells, as well as Yingli Panda N-type silicon cells. In market share, the International Technology Roadmap for PV (ITRPV) Expected N-type Crystalline Solar Cell from 2014 up to 18% in 2020 to 50% left and right.

N-type Crystalline Solar Cell industry level: 21% -24%

P- type Crystalline Solar Cell

In the bottom of the P-type semiconductor solar cells, low cost, high attenuation rate, 25 years after the decay rate can reach 15-20%. Incorporation of trivalent elements (such as boron) in pure silicon crystal, so that the position of substitution of silicon atoms in the lattice to form P-type semiconductor.

Industrialization Level - Domestic: 18.7% -19.2% overseas: 19.2% -20%

Battery Polycrystalline

Polycrystalline silicon solar cells combines the high conversion efficiency monocrystalline silicon cells and preparation of amorphous silicon thin film materials as well as long-life battery, etc. relatively simplified new generation of batteries, the conversion efficiency is generally about 12%, slightly lower than the silicon solar cells, there is no obvious efficiency recession, and may be prepared on an inexpensive substrate material, the cost is much lower than silicon cells, and more efficient than amorphous silicon thin film batteries.

Industry level: 17% -17.5%

- Q:How do solar cells perform in areas with high levels of air pollution and dust?

- Solar cells do not perform as efficiently in areas with high levels of air pollution and dust. The particles in the air can block sunlight from reaching the solar cells, reducing their ability to generate electricity. Additionally, the dust and pollution can accumulate on the surface of the solar panels, further decreasing their performance. Regular cleaning and maintenance are necessary to ensure optimal efficiency in such areas.

- Q:How does the solar panel produce it yourself?

- ?Step 5: Assemble the battery Place the titled titanium dioxide film face up on the table, drop one or two drops of electrolyte containing iodine and iodide ions on the membrane, and then press the conductive surface of the counter electrode down on the titanium dioxide film The The two pieces of glass were slightly staggered so as to use the exposed portions as the electrodes for testing. Use two clips to hold the battery, so that your solar cell is made

- Q:What is the role of solar cells in powering agricultural irrigation?

- The role of solar cells in powering agricultural irrigation is to harness the energy from the sun and convert it into electricity. This renewable energy source is used to operate irrigation systems, providing power for pumps and other equipment required for efficient water distribution to crops. Solar cells offer a sustainable and cost-effective solution, reducing reliance on fossil fuels and minimizing the environmental footprint of irrigation practices in agriculture.

- Q:Solar cell life for several years

- A solar cell is a device that converts light energy directly into electrical energy by photoelectric effects or photochemical effects.

- Q:How do solar cells perform in regions with high levels of snowfall and blizzards?

- Solar cells typically do not perform optimally in regions with high levels of snowfall and blizzards. The accumulation of snow on the surface of solar panels can significantly reduce their efficiency by blocking sunlight and preventing the cells from generating electricity. However, technological advancements such as anti-reflective coatings and tilted panel designs have been developed to mitigate the impact of snow accumulation. Additionally, regular maintenance and snow removal can help improve the performance of solar cells in such regions.

- Q:Many people said the usage of solar cell can reduce the cost overall, but does anyone agree with me that it actually cost a lot to operate a solar cell system?

- The reason why people said that is because the solar cell is using the sunlight, which is a free resources.

- Q:What is the role of solar cell inverters in grid-tied systems?

- The role of solar cell inverters in grid-tied systems is to convert the direct current (DC) electricity generated by the solar panels into alternating current (AC) electricity that can be used by the household or fed back into the electric grid. In addition to converting the electricity, solar cell inverters also monitor and control the flow of power, ensuring the system operates safely and efficiently.

- Q:What are the advantages of using solar cells?

- The advantages of using solar cells include renewable and sustainable energy generation, reduced greenhouse gas emissions, lower energy costs in the long run, and increased energy independence. Solar cells also require minimal maintenance and have a long lifespan, making them a reliable and durable energy solution.

- Q:Can solar cells be used to power water treatment plants?

- Yes, solar cells can be used to power water treatment plants. Solar energy can be harnessed by installing photovoltaic panels, which convert sunlight into electricity. This renewable energy source can provide a sustainable and cost-effective solution for powering water treatment plants, reducing dependence on fossil fuels and minimizing environmental impact.

- Q:Can solar cells be used for powering remote surveillance cameras?

- Yes, solar cells can be used to power remote surveillance cameras. Solar cells convert sunlight into electricity, making them a reliable and sustainable energy source for remote locations where power supply may be limited or unavailable. By harnessing solar energy, surveillance cameras can operate continuously without the need for frequent battery replacements or connection to electrical grids.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polycrystalline Solar Cells A GRADE Wholesale High Efficiency with Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords