Phenolic Foam/Polyurethane Sandwich Panel Production Line

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Phenolic Foam/Polyurethane Sandwich Panel Production Line

Introduction of the Equipment

Phenolic Foam/Polyurethane Sandwich Panel Production Line is a professional machine for manufacturing Sandwich Panels of which the core material is phenolic foam or polyurethane and of which both layers is embossed aluminium foil or colored steel. The thickness of sandwich panel is 20-200mm, the width 1200mm and the length according to customers’ request. The sandwich panels are used as the air ducts in Central air conditioning. The machine can used to make other insulation panel as long as the surface material is changed. The working principle of the machine is as below: mix the raw materials with a certain ration in a container and then pour the mixture on the interlayer of the sandwich panel. Then the raw materials has the chemistry reaction of foaming and solidifying. In the end the automatic tracking cutting machine cuts the panels into a certain length.

The Components and Its Function

The components include: the aluminium foil embossing machine, the raw material distributor, the aluminium foil/colored steel pre-heating installation, the material-baffling mechanism, the automatic tracking cutting machine, the roller supporters and brackets. All the components can be individually adjusted.

The Aluminium Foil Embossing Machine

The embossing machine include three parts: the charging unit, the embossing unit and the windin unit. It is used to emboss figures and logos under certain surface tension on the aluminium foil (Width: 1200mm, thickness: 0.08-0.12mm).

The Raw Material Distributor / The Raw Material Charging Unit

This device is installed at the forefront of the production line and the laminator. It can adjust the location and control the surface tension of the aluminum foil and the colored steel before entering the laminator.

The Aluminium Foil/Colored Steel Pre-heating Installation

Before entering the injection machine, the temperature of the aluminum foil or the colored steel must meet the requirement of the foaming technology of the PF or PU. And thermodynamic cycle device on the production line can control the temperature of the aluminum foil or colored steel.

The Material-baffling Mechanism

The material-baffling mechanism is used to stick Kraft paper to both sides of the lower aluminum foil before entering the injection machine. So there is a enclosed area between the upper aluminum foil and the lower one. With the Kratf paper, there will be no leakage of the raw materials when the machine is working.

The Reaction Injection Machine

The reaction injection machine is used to calculate the computation and mix of raw materials pro rata. In order to make the temperature of the raw materials meet the requirement of the foaming technology, the machine is equipped with heating, refrigerating and temperature control devices. In addition, People can control the pressure, the computation of the raw matrials by this machine. And the process of injection, cleaning and sweeping are automatically controlled. The equipment is equipped with three tanks, two for resin materials, one for curing agent material.

The Back-and-forth Injection Machine

This machine is used to apply the mixture on the lower aluminum foil or the colored steel. The injection head is drived by fluid drive, and its speed, moving frequency, transverse moving distance is adjustable.

The laminating conveyor is used for the laminating and the shaping of the sandwich panel. This machine adopts the driving structure of drag chain. The chain is made of fine aluminum alloy and is 18m long. The moving speed is 3-8m/min and is controlled by frequency conversion. If the customers want to improve the moving speed, they can customize a longer conveyor. The thickness is controlled by the space between the upper link plate and the lower one. The startup of the link plate is control by fluid drive. The 12 tilt cylinder is adjustable so that the link plates can stops at any position.

The Heated Air Circulation Device

To meet the expected requirement of foaming technology, the production line is equipped with a heated air circulation device. Its used to heat the link plates to 70℃. Its made up of one hot blast stove, one diesel-oil-drived stove and two temperature sensors. The temperatue sensors are placed at the inlet port and inside the conveyor so the operator can monitor the temperature fluctuation.

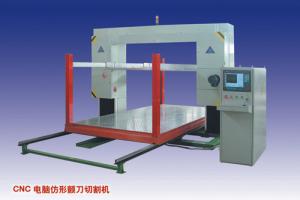

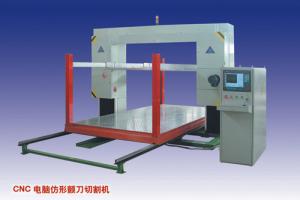

The Automatic Tracking Cutting Machine

The panels are cutted into different lengths by this machine.

MAIN TECHNICAL PARAMETER OF THE PRODUCTION LINE

Specification of Sandwich Panel | Width*Thickness (mm) | 1200×(20~200) |

The Production Speed | m/min | arbitrary |

The Embossing Speed | m/min | ≤20 |

The Mixing Speed | round/min | 4500 |

The Moving of Injection Head | times/min | ≤80 |

The Max temperature of the heated air circulation device | ℃ | 70 |

The Laminating Length of the Conveyor | M | 18.82 |

The Max start-up Speed of the Conveyor | mm | 300 |

Total Power | KVA | 85~125 |

The Specification of the Production Line | mm | 40950×5620×3700 |

The Specification of the Embossing Machine | mm | |

Weight | T | ≈34 |

Note: The above information is for our standard production line and we can make it according to customers request. We will send our techician to our customers to install and debug the machines.

- Q:Why construction gypsum is a good interior material and is suitable for outdoor use

- Plastering the walls and ceiling can also be directly painted paint and paste wallpaper Building gypsum water into gypsum slurry, into part of the lime, can be used as indoor paint paint After the painted wall of the official words delicate, white and beautiful General construction gypsum is not used for outdoor, and gypsum does not apply to load-bearing components, the most may be the production and application of gypsum board, China's current production of gypsum board is mainly paper gypsum board, gypsum hollow slab, gypsum decorative plate and Fiber gypsum board, and most of the interior wall and ceiling for the interior Building gypsum for outdoor use is rare, and there are also possible decorative garnishes made of cast gypsum, such as gypsum statues, decorative panels and various other decorations Personal humble opinion what

- Q:Only know that mahogany is a good material, the other really do not know, hopeful friends to provide some information

- Are you talking about solid wood furniture? Look at the following quotation: Solid wood furniture is made of natural wood furniture, furniture, the surface can generally see the real texture of wood

- Q:What are the sound insulation of the bar? Is there a noiseproof sound from the bar?

- Non-toxic, non-radioactive, anti-bacterial non-mildew; corrosion-resistant, anti-aging and decoration, and many other features, is a very good multi-functional new environmental protection and energy saving insulation, insulation, sound insulation, sound insulation; Sound insulation materials Poly-ceramic sound insulation properties: have good adhesion (easy to fall off) low thermal conductivity (insulation, insulation) light weight after the formation of complex pores formed after the sound absorption, insulation effect good weather resistance, can withstand a long time temperature and temperature difference and the four seasons temperature difference and the invasion of ultraviolet rays can be done according to user needs to do the appearance of decoration product economy, including material costs, production costs and construction costs of the total low cost The

- Q:The family has a lot of leather clothing, shoes, pigskin, sheepskin, leather have, but has been do not know how to clean, a piece of sheepskin leather inside a good piece of oil stained, bought a bottle of leather detergent, the results can only wipe the leather Surface, the inside can not wipe, I had to wash with a washing powder, the results after washing the leather completely lost luster, but also hard state, how to save? The The other leather I would not dare to wash with water, then how to clean? With a leather cleaner rubbed after the leather feel is not very clean, there is no shiny, completely like the original look like when to buy, do not have to use light agent? What brand?

- ② machine washing method: First, the use of advanced synthetic dry cleaning agent on the stains stains, and then into the dry cleaning machine for dry cleaning, cleaning time is generally 20-30 minutes, high speed 3 minutes or more, drying time 50 minutes , But should pay attention to drying temperature shall not exceed 50 ℃ In order to prevent damage to high-grade leather, can be used in the clean before the density is not thin thin fabric does not fade made of bags, leather clothes installed, into the dry cleaning machine dry cleaning, so that the treatment of clothing is often excellent results Although there are allowed to let the fade phenomenon, will be re-color to be covered Want to lose the shiny leather to restore the glory, can be diluted with a towel after the protein wipe

- Q:The electronic drawing that was sent to me by the design institute was not open on my computer. The

- Edit the entry dwgDWGAutoCAD graphics file, is a two-dimensional graphic file

- Q:What are the prospects for nanotechnology in the steel metallurgy industry? Best exemplified.

- Material is the material used to produce objects, devices, components, machines and other products used for life and production

- Q:What kind of waterproof repair agent as a moisture-proof decoration design materials?

- Currently on the market there are a lot of home for the use of convenient repair agent, and some only with the same as the gap to spray the gap can be spray, the operation is very convenient

- Q:I would like to ask a single general electronic energy meter common technical specifications is how much? Is the LCD screen?

- 643 Earth leakage current at 11 times the rated supply voltage, a total of two test your first two home Previous 12 Next Last Go to page 12 Total 2365 characters Author: Anonymous Source: The The design and implementation of the remote multi-channel remote detonator 5 requirements ▲ 5

- Q:How is the multi-functional waterproof coating? How much is a bucket?

- The quality of the effect is not very good You can Google Oriental Rainbow's official website, there are rainbow days cat flagship store and other links will have the price and product display, I suggest you choose the East Rainbow waterproof products and standardized construction team, the East Rainbow is the best quality Waterproof listed companies JSA-101 polymer cement waterproof coating "Rainbow" brand JSA-101 polymer cement waterproof coating is a two-component water-based waterproof coating, liquid material is a high-quality polymer emulsion and a variety of functional additives, Material is composed of special cement and a variety of additives, the use of a certain percentage of mixed use

- Q:The old roof to re-laying insulation materials and sand cover paving waterproof material about how much cost

- You can Google Oriental Rainbow's official website, there are rainbow days cat flagship store and other links will have the price and product display, you can also contact Rainbow customer service, it is recommended that you choose the East Rainbow waterproof products and standardized construction team, the East Rain rainbow is the best quality waterproof listed companies RPUF-371 sprayed rigid polyurethane waterproof insulation integrated system "rain rainbow" spray foam polyurethane waterproof insulation integrated system is made of foam polyurethane foam waterproof insulation integrated material and protective surface layer constitute

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Phenolic Foam/Polyurethane Sandwich Panel Production Line

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords