Paddle Laminating Roller-vacuum infusion process

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

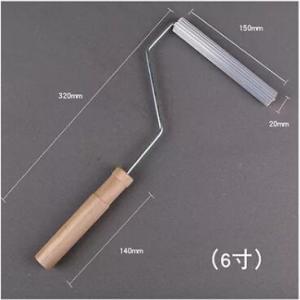

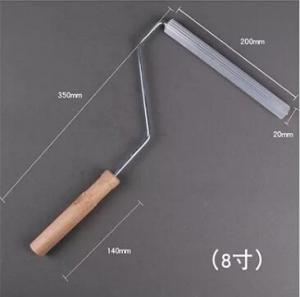

Paddle Laminating Roller

Product Description

Paddle Laminating Roller is widely used in the production of glass fiber reinforced plastic, and the inner surface of the bubble roller puncture, for removing air bubbles from lamination, leveling and compaction of resin coating to drive bubbles.

Technique Data

Type: | Roller Brush |

Handle: | Wooden and plastic |

Brush Material: | Aluminum |

Feature | Non-slip handle, multi-size, good material, high quality, durable |

Use | Remove air bubbles |

Color | Customized |

Size | 2‘’3‘’4‘’5‘’6‘’8‘’ |

MOQ | 100pcs |

Delivery Detail | About 15-20 days after having received the deposits. |

- Q:Can fiberglass chopped strand be used in electrical grounding applications?

- No, fiberglass chopped strand should not be used in electrical grounding applications. Fiberglass is a non-conductive material, meaning it does not conduct electricity. In electrical grounding applications, a conductive material is required to ensure the safe dissipation of electrical charges. Copper or other metals are typically used for this purpose as they have good electrical conductivity.

- Q:Can fiberglass chopped strand be used in aerospace composites?

- Yes, fiberglass chopped strand can be used in aerospace composites. It is commonly used as a reinforcement material in composite structures due to its high strength-to-weight ratio, excellent electrical insulation properties, and resistance to corrosion.

- Q:Can fiberglass chopped strand be used in sports equipment?

- Yes, fiberglass chopped strand can be used in sports equipment. It is commonly used in the manufacturing of various sports equipment such as skis, snowboards, surfboards, baseball bats, and hockey sticks. The fiberglass reinforcement provides strength, stiffness, and durability to these products, making them suitable for high-performance sports activities.

- Q:Can fiberglass chopped strand be used in chemical pipelines?

- No, fiberglass chopped strand cannot be used in chemical pipelines as it is not chemically resistant and may degrade or react with certain chemicals.

- Q:What are the packaging options for fiberglass chopped strand?

- The packaging options for fiberglass chopped strand typically include bulk bags, cardboard boxes, and plastic bags.

- Q:How is fiberglass chopped strand used in the wind energy industry?

- Due to its outstanding strength, durability, and lightweight characteristics, fiberglass chopped strand finds extensive use in the wind energy sector. Its primary application lies in the manufacturing of wind turbine blades, which play a crucial role in converting wind energy into electrical power. To incorporate the chopped strand form of fiberglass into the manufacturing process, a technique called resin infusion is commonly employed. In this process, the chopped strands are mixed with a resin matrix, typically epoxy or polyester, to create a composite material. This composite material is then molded into the desired shape, which, in the wind energy industry, refers to the wind turbine blade. By acting as reinforcement within the composite material, the chopped strands provide structural integrity and enhance the overall strength of the wind turbine blade. Fiberglass chopped strand possesses high tensile strength, enabling it to withstand the immense forces and stresses experienced by wind turbine blades during operation, including wind loads, turbulent conditions, and rotational forces. Moreover, the lightweight nature of fiberglass chopped strand offers advantages in the wind energy sector. Lighter wind turbine blades require less energy to rotate, thus improving the overall efficiency of the wind turbine. Additionally, the use of lightweight materials reduces the weight of the wind turbine, making transportation, installation, and maintenance more manageable and cost-effective. Furthermore, fiberglass chopped strand exhibits excellent corrosion resistance, an essential attribute in the wind energy industry where wind turbines are frequently exposed to harsh environmental conditions, such as saltwater spray, humidity, and temperature fluctuations. This corrosion resistance ensures the longevity and reliability of wind turbine blades, reducing the need for frequent maintenance and replacement. In conclusion, fiberglass chopped strand is an indispensable material in the wind energy sector, offering strength, durability, lightweight characteristics, and corrosion resistance to wind turbine blades. By utilizing this versatile material, the wind energy industry can optimize the performance, efficiency, and lifespan of wind turbines, thereby contributing to the production of clean and sustainable energy.

- Q:Is fiberglass chopped strand electrically conductive?

- No, fiberglass chopped strand is not electrically conductive. It is made from glass fibers that are coated with a non-conductive material, typically a resin, which provides insulation and prevents the flow of electricity. This makes fiberglass chopped strand suitable for use in electrical insulation applications where electrical conductivity is not desired.

- Q:Can fiberglass chopped strand be used in aerospace structural components?

- Yes, fiberglass chopped strand can be used in aerospace structural components. It is a commonly used material for various aerospace applications due to its lightweight, high strength-to-weight ratio, and excellent corrosion resistance properties. Additionally, it can be easily molded into complex shapes, making it suitable for aerospace structural components that require intricate designs.

- Q:Is fiberglass chopped strand resistant to abrasion?

- Yes, fiberglass chopped strand is generally resistant to abrasion. Fiberglass is known for its durability and strength, which makes it highly resistant to wear and tear caused by abrasion. The chopped strands are interwoven and bonded together, creating a strong and resilient material that can withstand abrasive forces. However, the exact level of resistance may vary depending on the specific composition and manufacturing process of the fiberglass chopped strand. It is always advisable to consult the product specifications or the manufacturer for specific information regarding the abrasion resistance of a particular fiberglass chopped strand product.

- Q:Can fiberglass chopped strand be used in roofing materials?

- Yes, fiberglass chopped strand can be used in roofing materials. Fiberglass chopped strand is a common reinforcement material used in the manufacturing of various roofing materials such as shingles, tiles, and membranes. It offers excellent strength and durability, making it an ideal choice for withstanding harsh weather conditions and prolonging the lifespan of the roofing system. The chopped strands are typically mixed with other materials such as asphalt or resins to create a composite that enhances the structural integrity and resistance of the roofing materials. Additionally, fiberglass chopped strand is lightweight, fire-resistant, and provides good thermal insulation, which further contributes to its suitability for roofing applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Paddle Laminating Roller-vacuum infusion process

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords