Microporous Calcium Silicate Insulation Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Micropore Insulation Board ,Heat Insulation materials

| Type: | Other Heat Insulation Materials | Place of Origin: | China (Mainland) | Brand Name: | |

| Model Number: | HCS | Color: | white | Apparent Density: | 220 +/- 10% |

| Heat Conductivity: | 0.060 | Highest Working Temperature: | 1050 | Material: | Xonotlite and reinforced glass fiber |

Packaging & Delivery

| Packaging Details: | Standard Fumigation Wooden pallet or Carton Package with Plastic Sheet inside |

| Delivery Detail: | Generally within 2 weeks after receipt of deposit |

Specifications

Microporous calcium silicate insulation board

experienced manufacturer

Size:1000*600mm,600*150mm

ISO9001:2008

Microporous calcium silicate insulation board

It is mixed with Xonotlite and reinforced glass fibre with high service temp. (1050 celsius),good heat insulation, low bulk density, high strength, good durability and so on.

Product characteristics:

² Good durability, can bear high temperature within the limit of continuous heat load,

² Low thermal conductivity, in the whole range are used with unmatched adiabatic performance.

² Light weight, high strength. It is the highest in these hard thermal insulation products.

² Better durability, use for a long time without powder.

² Construction with ordinary carpenter applicability, tools can be optional cut products.

² Used safety, hygiene. Excluding asbestos, sulfur, chlorine such poisonous substances.

² Fear water, but after drying also can be used.

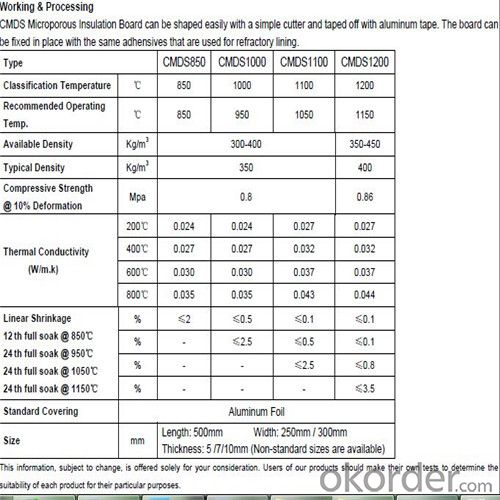

HCS Physical Performance Index

Items | Unit | HCS-170 | HCS-220 | HCS-270 |

Bulk Density | Kg/m3 | 170(±10%) | 220(±10%) | 270(±10%) |

Pressure Strength | MPa | ≥0.40 | ≥0.50 | ≥0.60 |

Flexural Strength | MPa | ≥0.30 | ≥0.35 | ≥0.40 |

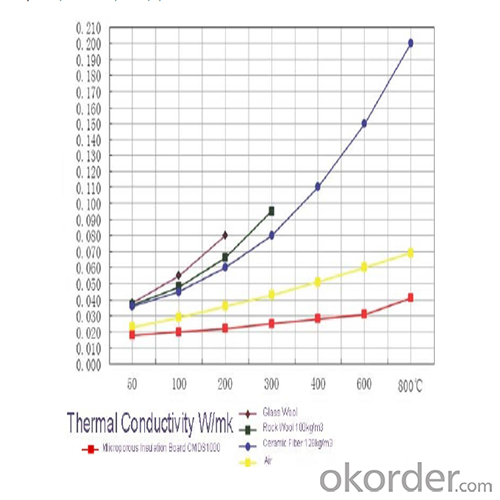

Thermal Conductive | W/m.k | ≤0.048 +0.00011t | ≤0.050 +0.00011t | ≤0.056 +0.00011t |

Temp. limit | degrees | 1000 | 1050 | 1050 |

Linear Shrinkage | % | ≤1.50 (1000,3hrs) | ≤1.50 (1000,3hrs) | ≤1.50 (1000,3hrs) |

Block Sizes and Dimensional Tolerances

Length(±3mm) | Width(±3mm) | Thickness(+2mm,—1.5mm) |

610 | 303,300,150 | 25—140 |

600 | 300 | 25—140 |

400 | 250 | 25—140 |

1000 | 500 | 25—140 |

1200 | 600 | 25—140 |

We also supply special size and type.

Standard Dimension:

1000(900)×600(500)×5-20mm

We can also manufacture the special dimensions as customers need.

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C,Western Union,Moneygram,Paypal are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Thanks for your coming in,if there is any question,I will be glad to help you.

- Q:Are glass fiber textiles resistant to moisture absorption or retention?

- Yes, glass fiber textiles are highly resistant to moisture absorption and retention.

- Q:Are microfiber fabrics priced per square gram, or are other prices heavier and higher? Where is the factory specializing in the last microfiber fabric?

- Feel different, wear on the body is also differentSynthetic fibers are synthetic, but fibers are naturalAfter rubbing, the chemical fiber will have static electricity...

- Q:Can glass fiber textile be used in electronics?

- Yes, glass fiber textile can be used in electronics. It is commonly used as a reinforcement material in printed circuit boards (PCBs) to provide mechanical strength and insulation. Additionally, it is also used in the manufacturing of electrical cables and connectors to enhance their durability and conductivity.

- Q:Can glass fiber textiles be used in the packaging industry?

- Yes, glass fiber textiles can be used in the packaging industry. Glass fiber textiles are known for their high strength and durability, making them suitable for packaging applications that require protection and stability. They can be used to create packaging materials such as bags, containers, and wrapping materials. Glass fiber textiles provide excellent resistance to tearing, punctures, and moisture, ensuring that the packaged goods are well-protected during transportation and storage. Additionally, they can offer thermal insulation and fire resistance properties, which are important considerations in certain packaging applications. Overall, glass fiber textiles can be a reliable and effective choice for the packaging industry.

- Q:Can glass fiber textiles be used for reinforcement in plastic bottles?

- Yes, glass fiber textiles can be used for reinforcement in plastic bottles. The glass fibers provide added strength and durability to the plastic bottles, making them more resistant to pressure and impact.

- Q:Please analyze the differences between the two fabrics. The more detailed, the better. Thank you

- What is bamboo fiber?Bamboo fiber is a kind of green environmental protection fiber through high-tech means extracted from bamboo, bamboo is consisted of main components (lignin, cellulose and hemicellulose) is a cellulose, mainly used in high-end fabrics, to create a romantic gorgeous beauty and health care function, healthy fiber has the most in twenty-first Century development prospects. We can never forget the good feeling of bamboo fiber ---- thin, soft, slippery, bright, tough, resistant and drooping. Is perception, is also feeling; fine - unit bamboo fiber fineness, has a unique sense of velvet; soft - soft than cotton is soft; slip - smootheven; bright -- good whiteness, bright color, strong toughness; toughness, good elasticity; resistance - longitudinal and transverse strength, and stable and uniform strong vertical, good drape.

- Q:Can glass fiber textiles be used in reinforcement of foam materials?

- Glass fiber textiles have the capability to reinforce foam materials, resulting in a notable enhancement in their overall mechanical properties. Due to its remarkable strength and stiffness, glass fiber is widely utilized as a reinforcing material. When glass fiber textiles are incorporated into foam materials, they serve as a reinforcement, imparting additional strength and rigidity to the foam structure. This reinforcement effectively heightens the foam's ability to resist bending, compression, and impact, making it suitable for a variety of applications that demand increased strength. Furthermore, glass fiber textiles also contribute to the foam's dimensional stability and resistance against heat, chemicals, and moisture. Consequently, glass fiber textiles present themselves as a viable option for reinforcing foam materials.

- Q:What are the applications of glass fiber textile?

- Glass fiber textiles have a wide range of applications in various industries due to their unique properties. Here are some of the key applications of glass fiber textile: 1. Reinforcement in Composites: Glass fiber textiles are extensively used as reinforcements in composite materials. They are incorporated into plastic or resin matrices to enhance the strength, stiffness, and durability of the final product. This makes them ideal for applications in automotive parts, aerospace components, and construction materials. 2. Insulation: Glass fiber textiles have excellent thermal insulation properties, making them suitable for applications in buildings, industrial equipment, and appliances. They can effectively reduce heat transfer, prevent energy loss, and provide fire resistance. Glass fiber insulation is commonly used in wall insulation, pipe insulation, and HVAC systems. 3. Filtration: Glass fiber textiles are used in various filtration systems due to their high porosity and retention efficiency. They can effectively remove particulate matter from air or liquids, making them ideal for applications in air filters, water filters, and oil filters. Glass fiber filters are commonly used in industrial processes, automotive engines, and HVAC systems. 4. Electrical Insulation: Glass fiber textiles have excellent electrical insulation properties and can withstand high temperatures. They are used as insulation materials in electrical cables, transformers, and motors. Glass fiber textile tapes or fabrics are wrapped around conductors to provide insulation and protect against electrical breakdown. 5. Reinforcement in Textiles: Glass fiber textiles can be blended with other fibers, such as cotton or polyester, to improve the strength and durability of textile materials. This makes them suitable for applications in sportswear, protective clothing, and upholstery fabrics. 6. Geotextiles: Glass fiber textiles can be used as geotextiles in civil engineering and construction projects. They can provide reinforcement, erosion control, and separation functions. Glass fiber geotextiles are used in road construction, embankments, retaining walls, and landfills. Overall, glass fiber textiles are versatile materials with a wide range of applications across various industries. Their unique properties make them desirable for reinforcement, insulation, filtration, electrical insulation, textile reinforcement, and geotextile applications.

- Q:Can glass fiber textiles be used in aircraft interiors?

- Glass fiber textiles have the capability to be utilized in the interiors of aircraft. Renowned for their remarkable strength-to-weight ratio, glass fiber textiles are well-suited for a range of applications within the aerospace sector. Within the confines of aircraft interiors, these textiles find their purpose in upholstery, seat covers, curtains, and carpets. They provide numerous benefits including fire resistance, durability, and ease of maintenance. Furthermore, the versatility of glass fiber textiles allows for weaving them into various patterns and designs, thus enabling customization and enhancing the aesthetic allure of the aircraft cabin.

- Q:Can glass fiber textiles be used in automotive interiors?

- Yes, glass fiber textiles can be used in automotive interiors. Glass fiber textiles, also known as fiberglass textiles, are lightweight and have excellent strength-to-weight ratio, making them suitable for a variety of applications in the automotive industry. These textiles are commonly used for reinforcing composites and providing structural support in various parts of the vehicle, including interior components. Glass fiber textiles can be used for upholstery and lining materials, offering durability and resistance to wear and tear. They are also fire-resistant, making them a safer choice for automotive interiors. Additionally, glass fiber textiles can be molded into different shapes and sizes, allowing for customization and integration into various interior designs. Moreover, glass fiber textiles offer thermal and acoustic insulation properties, helping to improve the overall comfort and noise reduction inside the vehicle. They can be used as insulation liners in the doors, roof, and floor panels, contributing to a quieter and more comfortable driving experience. In conclusion, glass fiber textiles are a versatile and suitable material for automotive interiors due to their lightweight, strength, durability, fire resistance, customization options, and insulation properties. Their use in automotive interiors helps enhance the overall quality, safety, and comfort of the vehicle.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Microporous Calcium Silicate Insulation Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords