JIS Standard Structural Steel H-beam all Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offeringJIS Standard Structural Steel H-beam at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Product Advantages:

OKorder's JIS Standard Structural Steel H-beam are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

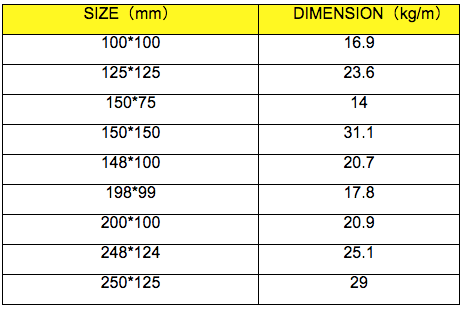

Specifications of JIS Standard Structural Steel H-beam

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

Usage & Applications of JIS Standard Structural Steel H-beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of JIS Standard Structural Steel H-beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of JIS Standard Structural Steel H-beam

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q:What are the common connections used for steel H-beams?

- The common connections used for steel H-beams are typically welded or bolted connections.

- Q:Are steel H-beams resistant to pests like termites?

- Yes, steel H-beams are highly resistant to pests like termites. Unlike wooden beams, which are prone to termite infestations, steel H-beams are not a food source for termites and do not provide a suitable environment for them to thrive. Termites primarily feed on cellulose, which is found in wood, but steel is not made of organic material and therefore does not attract termites. Additionally, steel H-beams are not susceptible to moisture damage or decay, which are other factors that can attract and sustain termite colonies. Therefore, using steel H-beams in construction significantly reduces the risk of termite infestation and damage to the structure.

- Q:How do steel H-beams perform in extreme weather conditions, such as high winds or heavy snow?

- Steel H-beams exhibit superior strength and durability, rendering them highly dependable in harsh weather conditions such as strong winds or heavy snowfall. Their distinctive shape and structural design effectively combat bending, twisting, and buckling forces, making them an ideal solution for confronting the challenges posed by severe weather. During periods of high winds, steel H-beams demonstrate outstanding performance due to their exceptional stiffness and ability to withstand wind loads. The H-shaped cross-section of the beam enhances stability and prevents deflection or damage even in the face of powerful gusts. This characteristic makes H-beams a favored choice for structures situated in hurricane-prone areas or regions with frequent high winds. Likewise, steel H-beams are exceptionally well-equipped to handle substantial snow loads. Their robust construction and high load-bearing capacity enable them to support the weight of accumulated snow without experiencing significant deformation or failure. This feature is especially crucial in areas that experience frequent snowstorms, as H-beams guarantee the structural integrity of buildings, bridges, or other infrastructures in such extreme conditions. Furthermore, steel H-beams not only resist wind and snow loads but also exhibit remarkable durability against corrosion and rust. This is achieved through the application of protective coatings and treatments during the manufacturing process. These coatings prevent the formation of rust and ensure the long-lasting performance of the beams, even in harsh weather environments. In conclusion, steel H-beams have a well-established reputation for exceptional performance in extreme weather conditions such as high winds or heavy snow. Their strength, stability, and resistance to external forces and corrosion make them a reliable choice for a variety of construction projects. This provides engineers, architects, and property owners with peace of mind, knowing that their structures will remain intact even in the face of severe weather.

- Q:How do steel H-beams contribute to the overall sustainability of a structure?

- Steel H-beams contribute to the overall sustainability of a structure in several ways. Firstly, steel is a highly durable material with a long lifespan, reducing the need for frequent replacements or repairs. This increases the longevity of the structure and minimizes waste generation. Additionally, steel is a recyclable material, meaning that H-beams can be easily repurposed or recycled at the end of their life cycle, reducing environmental impact. Moreover, steel H-beams have a high strength-to-weight ratio, allowing for lighter and more efficient designs, which can result in reduced energy consumption during construction and operation. Overall, the use of steel H-beams promotes sustainable practices by offering durability, recyclability, and energy efficiency in structural design.

- Q:Can steel H-beams be used in the construction of railway bridges?

- Yes, steel H-beams can be used in the construction of railway bridges. They are commonly used due to their high strength, durability, and ability to withstand heavy loads, making them suitable for supporting the weight of trains and ensuring the structural integrity of the bridge.

- Q:How are steel H-beams tested for quality and performance?

- To ensure the quality and performance of steel H-beams, rigorous testing processes are implemented. These tests aim to assess the structural integrity and strength of the H-beams, ensuring they meet the necessary standards and specifications. The primary test conducted on steel H-beams is the tensile test, which measures their ability to withstand pulling or stretching forces. A sample of the H-beam is progressively loaded until it reaches its maximum load-bearing capacity. The test results determine the H-beam's yield strength, ultimate tensile strength, and elongation properties, providing insights into its ductility and resistance to tension-induced deformation. Another essential test is the compression test, which evaluates the H-beam's capacity to withstand compressive forces without collapsing or buckling. A sample of the H-beam is subjected to a compressive load until failure occurs. The load at failure and the H-beam's behavior during the test are analyzed, determining its compressive strength, a critical factor for its structural performance. Furthermore, bend tests are conducted on steel H-beams to assess their ability to withstand bending forces without fracturing or excessive deformation. A sample of the H-beam is subjected to a bending moment until it reaches a specified angle. The test observes the H-beam's behavior, noting any signs of cracking or failure. This ensures that the H-beam possesses sufficient flexibility and structural integrity to endure bending forces. Moreover, visual inspections are carried out on steel H-beams to identify any surface defects or irregularities that may affect their quality. These inspections involve checking for cracks, surface finish, dimensions, and straightness. Any deviations from the specified standards are recorded and addressed accordingly. In conclusion, steel H-beams undergo comprehensive testing, including tensile, compression, and bend tests, as well as visual inspections. These tests guarantee that the H-beams meet the required quality standards, possessing the necessary strength and structural integrity to perform effectively in various construction applications.

- Q:Can steel H-beams be used for gymnasiums?

- Gymnasiums can indeed utilize steel H-beams. Due to their robustness and structural soundness, steel H-beams are widely employed in construction. They provide exceptional support for substantial spans and heavy loads, making them ideal for gymnasiums, which often necessitate expansive areas and lofty ceilings. Moreover, steel H-beams can be effortlessly tailored and manufactured to meet specific design prerequisites, granting flexibility in gymnasium design. Their resilience and ability to withstand fire, pests, and structural deterioration also establish them as a dependable choice for gymnasium construction. All in all, steel H-beams represent a favored and efficient alternative for constructing gymnasiums.

- Q:Can steel H-beams be used for signage structures?

- Yes, steel H-beams can be used for signage structures. They provide excellent strength and durability, making them suitable for supporting large and heavy signs. Additionally, H-beams can be easily customized and fabricated to meet specific design requirements, making them a popular choice for signage applications.

- Q:How do steel H-beams perform under heavy loads or stresses?

- Steel H-beams have been specifically engineered to handle immense loads and stresses. By virtue of their distinct shape, featuring a broad flange and a slender web, H-beams exhibit exceptional resistance against bending and torsional forces. This structural attribute enables them to adeptly distribute substantial loads and minimize deflection, rendering them highly suitable for an extensive array of applications, including bridges, buildings, and industrial structures. When subjected to burdensome loads or stresses, steel H-beams retain their structural integrity and offer exceptional support. The beam's expansive flange effectively combats compressive forces, while the narrow web confers resilience against tension forces. This harmonious blend of strength and rigidity renders H-beams an exemplary choice for both vertical loads and horizontal forces such as wind or seismic effects. Moreover, the utilization of steel as the principal material for H-beams yields supplementary advantages. Steel possesses elevated tensile strength, signifying its capacity to withstand considerable pulling or stretching forces without deformation or failure. Furthermore, steel is renowned for its durability, resistance to corrosion, and fire-resistant properties, guaranteeing the long-term stability and safety of structures even when subjected to substantial loads. In summary, steel H-beams excel in performance when faced with heavy loads or stresses. Their unique shape and material characteristics enable them to efficiently disseminate and resist diverse forms of forces, establishing them as a dependable choice for structural applications where strength and stability are paramount.

- Q:Can steel H-beams be used for wastewater treatment plants?

- Indeed, wastewater treatment plants can indeed employ steel H-beams. Due to their robustness and endurance, steel H-beams are frequently employed in construction. In the context of wastewater treatment plants, they serve multiple purposes, including bolstering heavy machinery and structures, delivering structural support for tanks and basins, and erecting walkways and platforms. The sturdiness of steel H-beams enables them to endure the harsh and corrosive conditions within wastewater treatment plants, rendering them a fitting choice for this particular utilization. Furthermore, steel H-beams can be easily fabricated and tailored to meet specific design prerequisites, allowing for versatility in various applications within wastewater treatment plants.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

JIS Standard Structural Steel H-beam all Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords