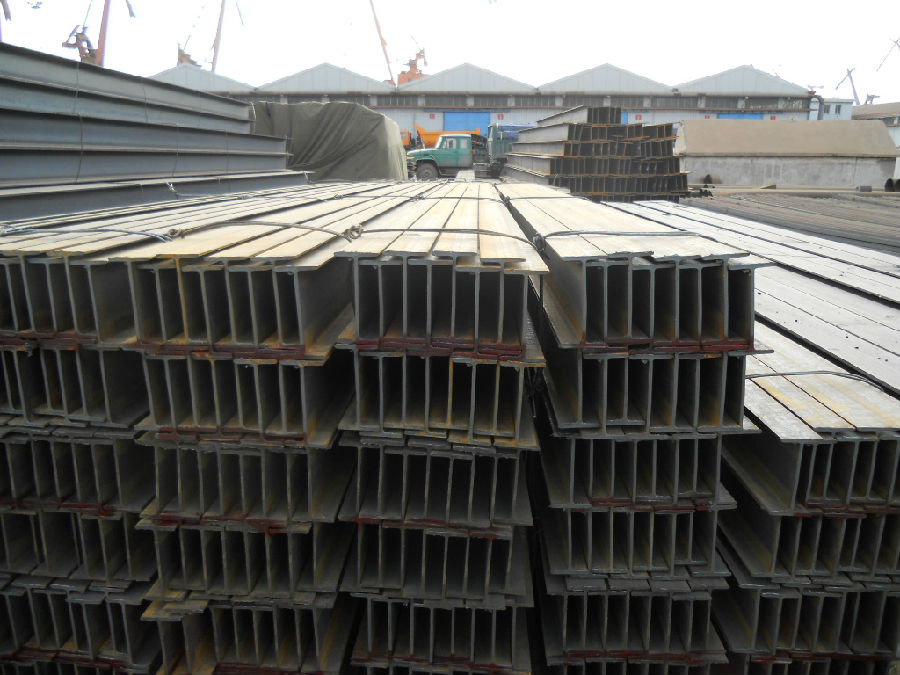

JIS Standard Hot Rolled H-beam Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Structural Steel H-beam JIS Standard at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Product Advantages:

OKorder's Structural Steel H-beam JIS Standard are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Standard: JIS

2. Grade: SS400

3. Length: 12m

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

H x B

(mm)

| T1 | T2 | JIS Weight

(kg/m)

| GB Weight

(kg/m)

|

100*100 | 6 | 8 | 16.9 | 17.2 |

125*125 | 6.5 | 9 | 23.6 | 23.8 |

150*75 | 5 | 7 | 14 | 14.3 |

148*100 | 6 | 9 | 20.7 | 21.4 |

150*150 | 7 | 10 | 31.1 | 31.9 |

175*90 | 5 | 8 | 18 | 18.2 |

175*175 | 7.5 | 11 | 40.4 | 40.4 |

198*99 | 4.5 | 7 | 17.8 | 18.5 |

200*100 | 5.5 | 8 | 20.9 | 21.7 |

194*150 | 6 | 9 | 29.9 | 31.2 |

200*200 | 8 | 12 | 49.9 | 50.5 |

248*124 | 5 | 8 | 25.1 | 25.8 |

250*125 | 6 | 9 | 29 | 29.7 |

244*175 | 7 | 11 | 43.6 | 44.1 |

250*250 | 9 | 14 | 71.8 | 72.4 |

298*149 | 5.5 | 8 | 32 | 32.6 |

298*201 | 9 | 14 | 65.4 | |

300*150 | 6.5 | 9 | 36.7 | 37.3 |

294*200 | 8 | 12 | 55.8 | 57.3 |

300*300 | 10 | 15 | 93 | 94.5 |

346*174 | 6 | 9 | 41.2 | 41.8 |

350*175 | 7 | 11 | 49.4 | 50 |

340*250 | 9 | 14 | 78.1 | 79.7 |

350*350 | 12 | 19 | 135 | 137 |

400*200 | 8 | 13 | 65.4 | 66 |

390*300 | 10 | 16 | 105 | 107 |

400*400 | 13 | 21 | 172 | 172 |

446*199 | 8 | 12 | 65.1 | 66.7 |

450*200 | 9 | 14 | 77.9 | 79.5 |

440*300 | 11 | 18 | 121 | 124 |

496*199 | 9 | 14 | 77.9 | 79.5 |

500*200 | 10 | 16 | 88.2 | 89.6 |

488*300 | 11 | 18 | 125 | 129 |

596*199 | 10 | 15 | 92.5 | 95.1 |

600*200 | 11 | 17 | 103.4 | 106 |

588*300 | 12 | 20 | 147 | 151 |

700*300 | 13 | 24 | 182 | 185 |

800*300 | 14 | 26 | 207 | 210 |

900*300 | 16 | 28 | 240.1 | 243 |

Usage & Applications of Hot Rolled Steel H-beam For Sale

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure.etc.

Packaging & Delivery of Hot Rolled Steel H-beam For Sale

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Hot Rolled Steel H-beam For Sale

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q:Are steel H-beams resistant to termites or pests?

- Yes, steel H-beams are resistant to termites and pests.

- Q:How do steel H-beams contribute to energy efficiency?

- Steel H-beams contribute to energy efficiency in several ways. Firstly, these beams are commonly used in the construction industry for the structural support of buildings and bridges. By providing a sturdy and reliable framework, H-beams help to reduce the need for excessive energy consumption during the construction process. This is because they allow for the efficient distribution of loads, minimizing the amount of materials and resources required for construction. Furthermore, steel H-beams are known for their durability and longevity. Unlike other materials, such as wood or concrete, steel beams do not warp, rot, or deteriorate over time. This means that buildings and structures constructed using H-beams will require less maintenance and repair work, resulting in reduced energy consumption and costs in the long run. Moreover, steel is a highly recyclable material. H-beams can be easily melted down and repurposed, reducing the demand for new steel production. This recycling process requires less energy compared to the production of new steel, which helps to conserve energy resources and reduce greenhouse gas emissions. Additionally, steel H-beams have excellent thermal properties. They have a high thermal conductivity, which allows them to efficiently transfer heat and cold. This characteristic is particularly beneficial in energy-efficient building designs, as it helps to regulate temperature and reduce the need for excessive heating or cooling. By minimizing energy consumption for temperature control, steel H-beams contribute to overall energy efficiency in buildings. In summary, steel H-beams contribute to energy efficiency by reducing material waste during construction, providing long-lasting structural support, promoting recycling and reducing greenhouse gas emissions, and optimizing thermal properties for efficient temperature regulation. These factors make steel H-beams a sustainable and energy-efficient solution for various construction applications.

- Q:Are Steel H-Beams resistant to warping or twisting?

- Steel H-Beams possess a high resistance to warping or twisting due to their unique design. The wide flange and vertical web of H-Beams contribute to their exceptional structural stability and ability to withstand bending forces. The symmetrical shape of H-Beams ensures the even distribution of loads, thereby minimizing the risk of warping or twisting. Moreover, H-Beams are commonly manufactured using high-strength steel, enhancing their ability to resist deformation when subjected to heavy loads or external forces. Consequently, Steel H-Beams are an optimal selection for a wide range of applications that demand robust and dependable structural components.

- Q:What are the different methods of installing steel H-beams?

- Installing steel H-beams can be done using various methods, depending on the project requirements and available resources. Below are some commonly used techniques: 1. The first method involves the use of heavy machinery like cranes or forklifts to lift and position the steel H-beams. This approach is typically employed for larger structures or when installing beams at significant heights. 2. Welding is another common technique used to connect steel H-beams either to each other or to other structural elements. It requires melting and fusing the metal to create a strong joint. Welding can be carried out on-site or in a fabrication shop, depending on the project's needs. 3. Bolting is a method where bolts and nuts are used to secure the steel H-beams together or to other structural components. Bolting is often favored in situations where future disassembly or modifications may be necessary. 4. Concrete embedment is employed when additional stability and support are required. Steel H-beams are embedded in concrete by creating holes in the concrete structure and placing the beams into them. The beams are then held in place as the concrete sets. 5. Steel plates and brackets can also be utilized to connect steel H-beams to other structural elements. These plates are typically attached to the beams through bolting or welding and then affixed to the desired location. It is crucial to consider factors such as project requirements, structural design, and available resources when choosing the appropriate method for installing steel H-beams. Seeking advice from a structural engineer or construction professional is highly recommended for determining the most suitable installation approach for a specific project.

- Q:Can steel H-beams be used for parking structures?

- Yes, steel H-beams can be used for parking structures. They are commonly used in the construction of multi-level parking garages due to their strength, durability, and load-bearing capabilities. The H-beams provide structural support and stability to the parking structure, making them a suitable choice for this application.

- Q:Can steel H-beams be used for data centers?

- Indeed, data centers can utilize steel H-beams. These beams are frequently employed in construction endeavors as they possess impressive strength, endurance, and load-bearing capacities. In order to sustain the weight of equipment and infrastructure, data centers necessitate robust and steadfast structures, making steel H-beams an ideal choice. Moreover, H-beams can be effortlessly assembled and tailored to fit the precise layout and needs of a data center. By employing steel H-beams, data centers guarantee the stability and structural soundness vital for supporting the crucial operations and equipment housed within these establishments.

- Q:How are steel H-beams connected to other structural elements?

- Steel H-beams are commonly connected to other structural elements using various methods such as welding, bolting, or using specialized connectors.

- Q:How do steel H-beams contribute to the structural integrity of buildings?

- Steel H-beams play a crucial role in supporting the structural integrity of buildings. These beams are designed to withstand heavy loads and provide stability and strength to the overall structure. The unique H-shape of these beams allows for efficient weight distribution, making them ideal for withstanding both vertical and horizontal loads. One of the key contributions of steel H-beams to the structural integrity of buildings is their ability to resist bending and deflection. The horizontal flanges on the top and bottom of the beam provide greater resistance against bending forces, ensuring that the beam remains rigid and maintains its shape under load. This characteristic is particularly important in high-rise buildings or structures with large spans, where the beams are subjected to significant loads. Furthermore, steel H-beams also contribute to the overall stability of the building. By connecting the beams to columns or other load-bearing elements, they create a rigid framework that prevents excessive movement or deformation during various external forces such as wind, earthquakes, or even the weight of the building itself. This stability is crucial for ensuring the safety of the occupants and preserving the structural integrity of the entire building. Another advantage of steel H-beams is their versatility and adaptability. These beams can be easily fabricated to different lengths and sizes to suit the specific requirements of each building project. Additionally, they can be welded or bolted together to create larger structural elements or to form complex frameworks, allowing for greater flexibility in design and construction. In conclusion, steel H-beams are essential components in the construction industry as they significantly contribute to the structural integrity of buildings. Their ability to resist bending, provide stability, and their versatility in design and fabrication make them an ideal choice for supporting heavy loads and ensuring the long-term durability of structures.

- Q:Are steel H-beams compatible with different types of roofing materials?

- Yes, steel H-beams are compatible with different types of roofing materials. The versatility of steel H-beams allows for easy integration with various roofing systems, including shingles, metal panels, tiles, or even green roofs. The strength and durability of steel make it an excellent choice for supporting different roofing materials, ensuring stability and longevity.

- Q:Can steel H-beams be used in data center construction?

- Steel H-beams are indeed applicable for data center construction. Their strength, durability, and versatility make them a common choice in construction projects. They possess outstanding load-bearing capabilities, rendering them suitable for supporting heavy equipment and structures within data centers. Moreover, steel H-beams allow for flexible design and effortless customization to fulfill precise construction needs. By employing them, the stability and longevity of data centers are guaranteed, which explains their popularity in the construction industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

JIS Standard Hot Rolled H-beam Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords