Hot Selling H Beam Profile with Grade A Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

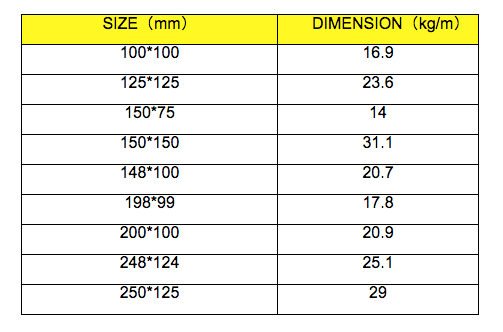

6. Sizes:

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: Can fit in the containers of 20fts the steel beams of 6M?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q:Can steel H-beams be used for transmission towers?

- Indeed, transmission towers can utilize steel H-beams. In the construction sector, steel H-beams find wide application, serving as support for bridges, buildings, and transmission towers. Their robustness and resilience render them ideal for bearing substantial loads and enduring severe weather. Moreover, the ease of fabricating and assembling steel H-beams contributes to their cost-effectiveness in constructing transmission towers.

- Q:Can steel H-beams be used in data centers and server rooms?

- Data centers and server rooms can indeed utilize steel H-beams. Their exceptional strength and ability to bear heavy loads make them a popular choice for structural support. In these spaces, where secure support for substantial equipment and racks is imperative, steel H-beams offer a dependable solution. They can function as either support columns or beams, ensuring both stability and structural integrity. Moreover, steel H-beams possess fire-resistant properties, a critical attribute in environments that prioritize fire safety, such as data centers and server rooms. Consequently, steel H-beams are a fitting option for delivering sturdy structural support in these settings.

- Q:How do steel H-beams contribute to the load-bearing capacity of a structure?

- Steel H-beams contribute to the load-bearing capacity of a structure through their unique design and material properties. The H-shaped cross-section of these beams provides a greater surface area compared to other structural shapes, which translates to increased strength and load-carrying capacity. The flanges, or top and bottom horizontal sections of the H-beam, are designed to resist bending and shear forces. They act as a platform to distribute the load evenly across the beam's length, ensuring efficient load transfer. The web, or vertical section, connects the flanges and provides additional rigidity and stability to the beam. Steel, being a strong and durable material, further enhances the load-bearing capacity of H-beams. It possesses high tensile and compressive strength, allowing the beams to withstand heavy loads and resist deformation. Additionally, steel has excellent resistance to fire, corrosion, and other environmental factors, ensuring the long-term structural integrity of the building. The versatility of H-beams is another factor contributing to their load-bearing capacity. They can be fabricated in various sizes and lengths, making them suitable for a wide range of applications and structural requirements. Moreover, H-beams can be easily joined together using welding or bolted connections, enabling the construction of complex and robust frameworks. In summary, steel H-beams contribute to the load-bearing capacity of a structure by providing a strong and efficient structural element. Their unique design, coupled with the strength and durability of steel, allows them to support heavy loads and ensure the overall stability and safety of the building.

- Q:Can steel H-beams be used for manufacturing facilities?

- Manufacturing facilities can indeed utilize steel H-beams. These beams are commonly employed in the construction industry for a range of purposes, including manufacturing facilities. With their exceptional strength, durability, and load-bearing capabilities, steel H-beams are well-suited for supporting the weight of heavy machinery, equipment, and structures within manufacturing plants. Moreover, H-beams offer a robust framework that can be easily fabricated and installed, making them an excellent option for constructing manufacturing facilities that necessitate expansive open spaces and wide spans. Furthermore, steel H-beams possess the capacity to endure high temperatures, rendering them appropriate for industries involving heat-intensive processes. In summary, steel H-beams are an adaptable and dependable choice for constructing manufacturing facilities, thanks to their structural integrity and capacity to handle substantial loads.

- Q:Can steel H-beams be used in mezzanine floors?

- Yes, steel H-beams can be used in mezzanine floors. They are commonly used as structural supports due to their high strength and load-bearing capacity, making them an ideal choice for creating additional floor space in buildings.

- Q:What are the different grades of steel used for manufacturing H-beams?

- There are several grades of steel that are commonly used for manufacturing H-beams. These grades vary in terms of their chemical composition and mechanical properties, which determine their suitability for different applications. Some of the commonly used grades include: 1. ASTM A36: This is a low carbon steel grade that is widely used for general structural purposes. It offers excellent weldability and machinability, making it a popular choice for H-beam manufacturing. 2. ASTM A572: This grade of steel offers higher strength and better corrosion resistance compared to A36. It is commonly used for applications that require higher load-bearing capacity, such as in heavy construction and bridge building. 3. ASTM A992: This grade is specifically designed for wide-flange shapes like H-beams. It offers higher yield strength and better ductility compared to A36, making it suitable for structural applications that require superior performance. 4. ASTM A588: This grade of steel is known for its high atmospheric corrosion resistance. It is often used in outdoor applications, such as bridges and buildings located in harsh environments. 5. ASTM A709: This grade is primarily used for construction of bridges and other infrastructure projects. It offers high tensile strength, excellent toughness, and improved weldability, making it suitable for H-beam manufacturing in such applications. It is important to note that the selection of a specific grade of steel depends on the requirements of the project, including the load-bearing capacity, environmental conditions, and other factors. Consulting with a structural engineer or steel supplier can help determine the most appropriate grade for a particular application.

- Q:What are the different load types that steel H-beams can withstand?

- Steel H-beams possess excellent versatility and suitability for a wide array of applications due to their ability to withstand diverse load types. These load types that steel H-beams can endure include: 1. Uniformly Distributed Load (UDL): Steel H-beams effectively bear UDL, which is the evenly spread weight across the entire beam length. An example of UDL could be the weight of a floor or a roof. 2. Point Load: Steel H-beams are also capable of resisting point loads, which are concentrated forces applied at a specific point or area on the beam. Instances of point loads include the weight of heavy equipment or machinery placed directly on the beam. 3. Torsional Load: Steel H-beams possess the capacity to withstand torsional loads, which arise from a twisting force applied to the beam. This is crucial for structures experiencing rotational forces, such as bridges or towers subjected to wind or seismic activity. 4. Lateral Load: Steel H-beams can endure lateral loads, also known as horizontal loads that act perpendicular to the beam's axis. This is essential in countering lateral forces caused by wind or earthquakes. 5. Axial Load: Steel H-beams are specifically designed to resist axial loads, which are forces acting along the beam's axis. These loads can be compressive (pushing the beam together) or tensile (pulling the beam apart). Axial loads are commonly encountered in columns or vertical components of a structure. 6. Shear Load: Steel H-beams exhibit the capability to withstand shear loads, which transpire when two forces act in opposite directions parallel to the beam's cross-section. If not appropriately considered in the design, shear forces can cause beam deformation or failure. It is important to acknowledge that the load capacity of steel H-beams varies depending on factors such as beam size, shape, steel type, and specific design considerations of the structure. Thus, consulting engineering specifications and calculations is crucial to ensure the appropriate selection and application of H-beams based on the specific load requirements of a given project.

- Q:Are steel H-beams fire-resistant?

- Yes, steel H-beams are fire-resistant. Steel is an inherently fire-resistant material due to its high melting point and low flammability. H-beams, being made of steel, can withstand high temperatures and retain their structural integrity during a fire.

- Q:H Elastic modulus of section steel

- The elastic modulus of steel is 2.1 * 10^7N/cm L.

- Q:Are there any design guidelines or codes for using steel H-beams?

- Design guidelines and codes exist to specify and require the use of steel H-beams in construction projects, guaranteeing their safe and efficient utilization in various structural applications. The American Institute of Steel Construction (AISC) Specification for Structural Steel Buildings is a highly recognized code for steel structure design. It offers comprehensive design guidelines, including the implementation of H-beams, for different types of structures like buildings, bridges, and industrial facilities. It encompasses material selection, member design, connection design, and fabrication requirements. The AISC code establishes criteria for the design of steel H-beams, encompassing load capacities, allowable stresses, and design standards for different loading conditions like gravity loads, wind loads, and seismic loads. It also provides recommendations for selecting suitable beam sizes and shapes based on structural requirements and applied loads. Additional design guidelines and codes, such as the Eurocode, British Standards, and Canadian Standards, also provide specifications for the use of steel H-beams in construction projects. While these codes may have slight variations in design approaches and methodologies, they generally cover similar topics and offer guidance on the safe and efficient use of H-beams. When working with steel H-beams in construction projects, it is crucial to consult the relevant design codes and guidelines applicable to your region or country. Adhering to these codes ensures the structural design is reliable, safe, and meets required standards. Additionally, involving a qualified structural engineer during the design process is essential to ensure the H-beams are properly sized and detailed to meet specific project requirements and local codes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Selling H Beam Profile with Grade A Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords