high temperature resistance silica fiber cloth

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Image:

Product Description & Application:

Silica fiberglass cloth is one high-temperature inorganic fiber with the molten temperature nearly 1700 degree Celsius, and the work for a long time at 900 degree Celsius.

Application:

Widely used as heat resistant and ablationresistasant material for rocket,missile and space vehicle;

High-temperature resistant,thermal insulation,refractory material;

Dust collect for high temperature gas;

Liquid filtration;Sound absorbing and thermal insulation for vehicle,motor bicycle;The thermal insulation protective materials for molten liquid filtration.

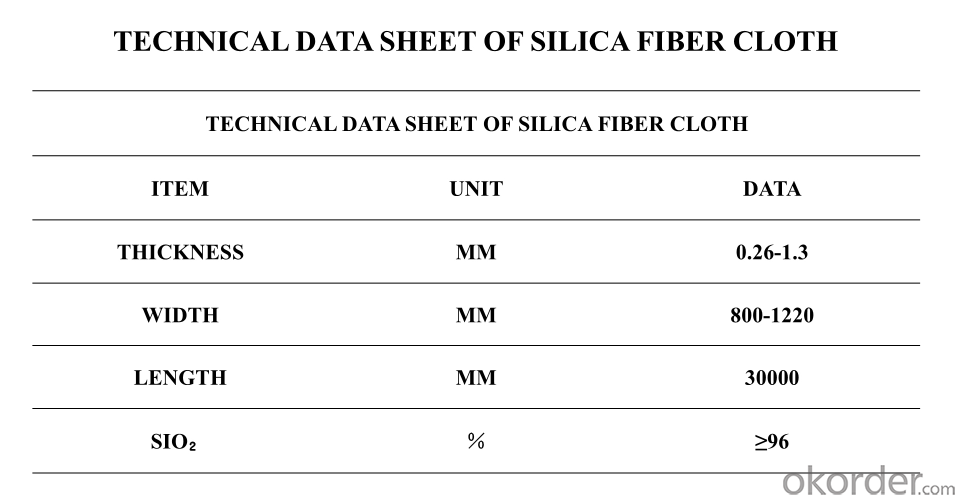

Product Capability:

SiO2>=96%;

High temperature resistant,higher thermal insulation,low thermal conductivity;

Thermal stability and chemical stability;

High strength and easy to manufacture;

Nontoxic and harmless to the environment.

Data Sheet:

Fiberglass products:

Fiberglass is a kind of long fiber. It has the advantage of high tensile strength, low thermal conductivity, corrosion resistance and good insulation.The working temperature ranges from 200-1000 degree Celsius. Main products: Fiberglass texturized yarn, cloth, tape, rope, sleeve,mesh,filter cap,friction thread (piece) and fiber netting,composite yarn etc.

- Q:Can fiberglass fabrics be used for soundproofing?

- Absolutely! Fiberglass fabrics have the incredible ability to be utilized for soundproofing purposes. When it comes to soundproofing, fiberglass is highly sought after due to its remarkable acoustic properties. It has the capacity to effectively absorb sound waves and diminish noise transmission, making it the perfect choice for any soundproofing project. The versatility of fiberglass fabrics allows them to be used in a multitude of ways, including as acoustic panels, curtains, or wall coverings, in order to decrease noise levels in residential, commercial, or industrial spaces. These fabrics are frequently employed in recording studios, home theaters, offices, and other settings where sound control is of utmost importance. The dense and porous structure of fiberglass enables it to effortlessly absorb and dissipate sound energy, ultimately resulting in a more serene and tranquil environment.

- Q:How does fiberglass fabric perform in terms of sound absorption?

- Fiberglass fabric performs exceptionally well in terms of sound absorption. Its porous structure and high density make it an effective material for reducing echo and reverberation. It can effectively absorb a wide range of frequencies, making it suitable for various applications such as acoustic panels, soundproofing curtains, and insulation in buildings.

- Q:Can fiberglass fabric be used for heat-resistant gaskets?

- Fiberglass fabric proves its suitability for heat-resistant gaskets due to its remarkable heat resistance properties. It emerges as a favored option for applications demanding resistance against high temperatures. It can endure temperatures reaching several hundred degrees Celsius without any degradation or melting. Consequently, fiberglass fabric emerges as an optimal material for heat-resistant gaskets, effectively sealing joints and impeding heat transfer amidst distinct components. Moreover, its chemical, water, and abrasion resistance further accentuate its appropriateness for gasket applications.

- Q:What is the typical warp and weft count of fiberglass fabrics?

- The specific application and desired strength and durability can cause variations in the warp and weft count of fiberglass fabrics. Generally, fiberglass fabrics tend to have a higher warp count compared to the weft count. This is because the warp yarns, running vertically, are thicker and stronger to ensure stability and resistance against stretching and tearing. Conversely, the weft yarns, running horizontally, are thinner and more flexible to allow the fabric to conform to different shapes and contours. The warp count for fiberglass fabrics typically ranges from 16 to 40 yarns per inch, while the weft count is slightly lower, ranging from 12 to 30 yarns per inch. These counts can also be measured in metric units, like yarns per centimeter. However, it's important to note that these counts may vary depending on the specific manufacturer, fabric weight, and intended use of the fiberglass fabric.

- Q:What is the advantage of coating waterproof layer with matrix reinforcing material?

- Waterproof layer construction, often in a waterproof coating is added in the glass fiber cloth or polyester fiber cloth as matrix reinforced material, its main purpose is: with the carcass reinforcing material deformability of gutter, eaves gutter, eaves, the water node location details, because the temperature deformation of roof structure is not synchronized, easy to deform and crack therefore, caused by leakage, in roof waterproof weak parts must be in the construction of large area coating waterproof layer, easy to leak in these lines or at least additional outward widening 200mm layer is coated with a cloth, enhance the anti deformation ability of waterproof film.

- Q:Is fiberglass fabric resistant to aging or deterioration?

- Yes, fiberglass fabric is highly resistant to aging or deterioration. Fiberglass is a synthetic material made from fine fibers of glass that are woven together to form a fabric. These fibers are highly durable and do not degrade easily over time. They are resistant to UV radiation, moisture, chemicals, and temperature fluctuations, making them ideal for various applications where longevity is crucial, such as insulation, construction, and marine industries. Additionally, fiberglass fabric is known for its high tensile strength, dimensional stability, and fire resistance, further enhancing its resistance to aging or deterioration. Overall, fiberglass fabric is a reliable and long-lasting material that can withstand the test of time.

- Q:What is the difference between non-woven fabrics, glass fiber cloth and geotextile?

- The exact name of the non-woven fabric shall be nonwoven or non-woven. Because it is a kind of form that does not require spinning weaving fabric, just a textile fiber or filament aligned or random, the formation of the fiber network structure, and then the mechanical, thermal or chemical methods and strengthening into. Nonwovens break through the traditional textile principle, and have the characteristics of short process flow, fast production, high yield, low cost, wide use and many sources of raw materials.

- Q:What is the best waterproof material for swimming pool?

- Waterproof coating: with waterproof paint painted over 2~3 times in the pool wall and the bottom of the pool (usually thicker than 2 mm), and then the surface of the tile;

- Q:Is fiberglass fabric suitable for use in medical applications?

- Yes, fiberglass fabric can be suitable for use in certain medical applications. It has excellent strength and durability, making it ideal for applications such as orthopedic casts and splints. However, it should be noted that fiberglass fabric may not be suitable for direct contact with open wounds or sensitive skin due to its potential for irritation.

- Q:Can fiberglass fabric be used in low-temperature applications?

- Yes, fiberglass fabric can be used in low-temperature applications. Fiberglass is known for its excellent thermal insulation properties, which makes it suitable for use in low-temperature environments. It is commonly used in applications such as cryogenic insulation, cold storage facilities, and refrigeration systems. Fiberglass fabric has a low thermal conductivity and is capable of withstanding extremely low temperatures without losing its structural integrity. Additionally, it is resistant to moisture, chemicals, and UV radiation, making it a durable and reliable choice for low-temperature applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

high temperature resistance silica fiber cloth

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords