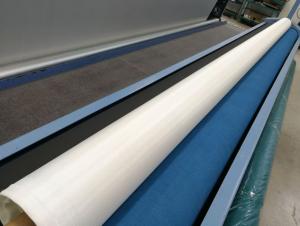

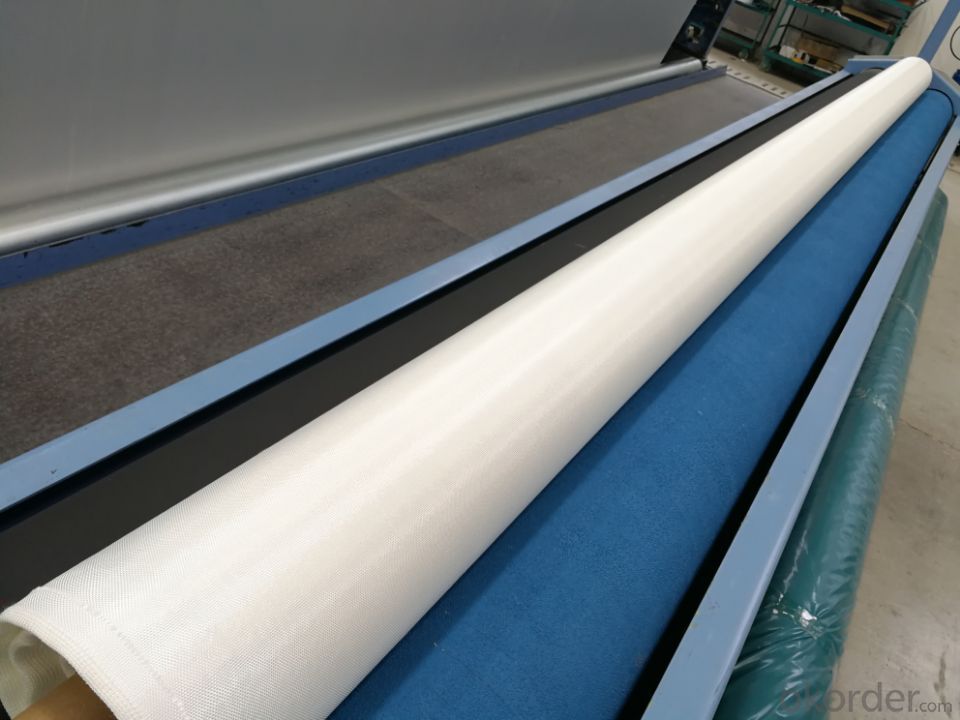

High Strength Woven Geotextile for Road Construction Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Strength PP Woven Geotextile

1. Description of High Strength PP Woven Geotextile

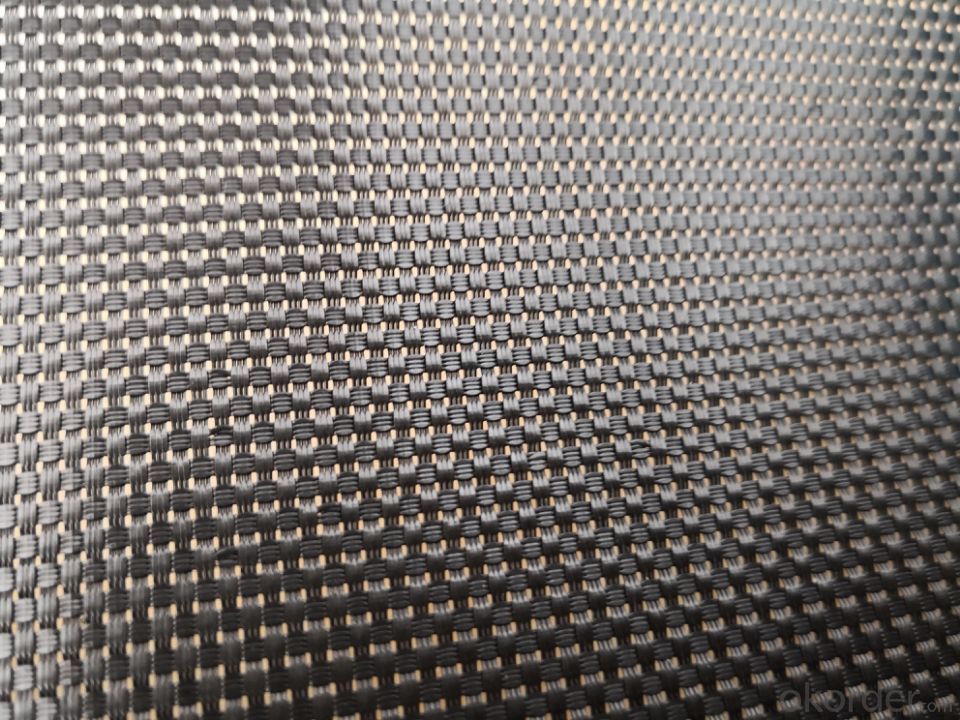

CMAX polypropylene woven geotextile is made from polypropylene flit yarn on circle weave machine, including circular loom and flat loom.

2. Specification of High Strength PP Woven Geotextile

Weight: 90gsm – 400gsm;

Width: 1m – 6m; Length: as clients’ required.

3. Technical Data Sheet of High Strength PP Woven Geotextile

Item | Unit | Index | ||||||

Unit Weight | g/m2 | 120 | 160 | 200 | 240 | 280 | 340 | 400 |

Breaking Strength in MD | KN/m | 20 | 30 | 40 | 50 | 60 | 80 | 100 |

Breaking Strength in CD | KN/m | 15 | 22 | 28 | 35 | 42 | 56 | 70 |

Elongation Rate | % | 25 | ||||||

Trapezoidal Tearing Strength | KN | 0.2 | 0.27 | 0.34 | 0.41 | 0.48 | 0.6 | 0.72 |

CBR Mullen Burst Strength | KN | 1.6 | 2.4 | 3.2 | 4.0 | 4.8 | 6.0 | 7.5 |

Vertical Permeability | Cm/s | 10^-1 ~10^-4 | ||||||

Sieve Size O90(O95) | Mm | 0.07 ~ 0.50 | ||||||

Variation | % | ±10 | ||||||

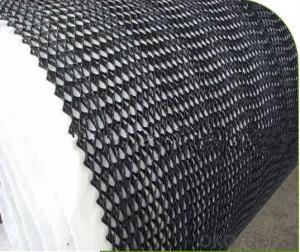

4. Property of High Strength PP Woven Geotextile:

1).Light weight, high strength, low elongation, easy to construct.

2).Reinforcement, separation, drainage and filtration, fencing function.

5. Application of High Strength PP Woven Geotextile

Railways, highways, sport fields, earthwork projects, tunnels, coal mines, walls and slopes, environmental protection and so on.

.

High Strength PET Woven Geotextile

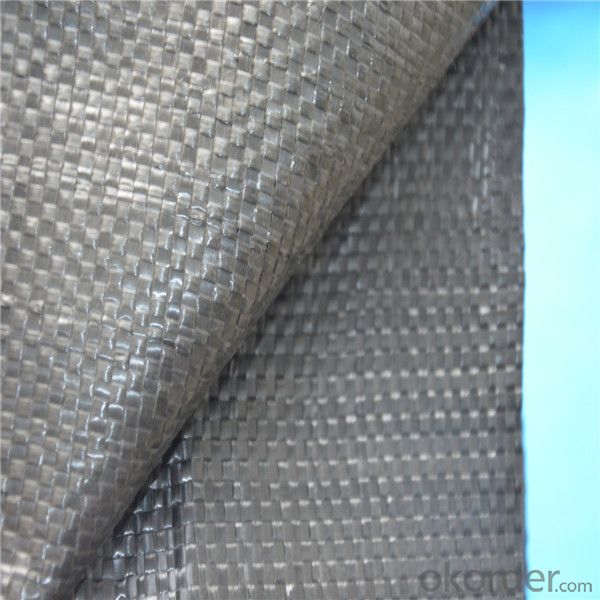

1. Description of PET Woven Geotextile

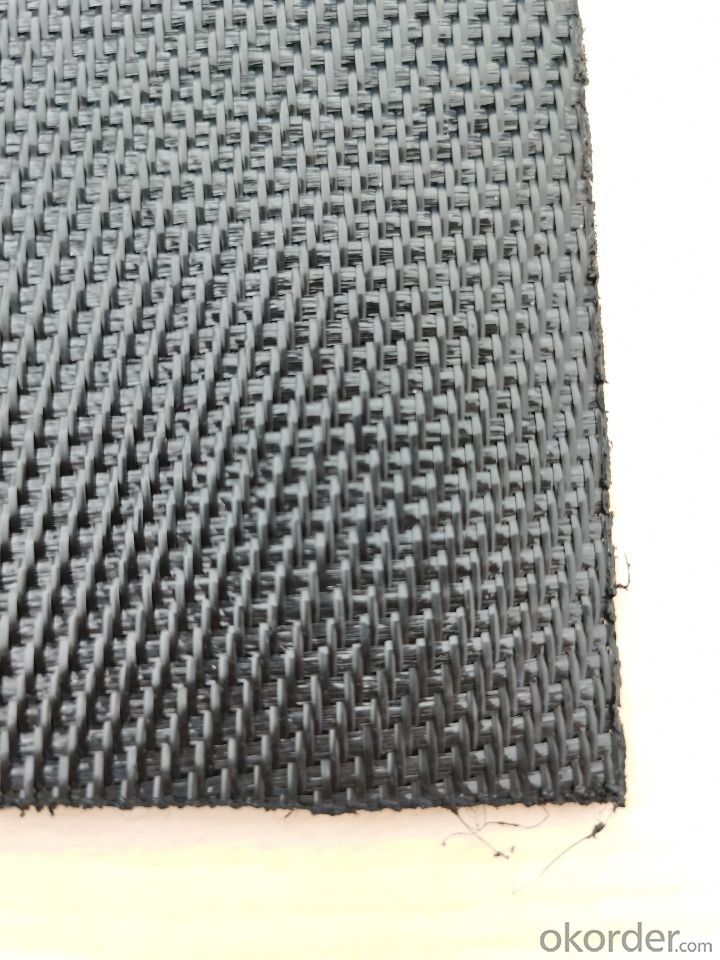

CMAX filament woven geotextile is made from polypropylene, high strength industrial synthetic fiber as the raw material, made through weaving technology.

2. Specification of PET Woven Geotextile

Breaking strength in MD(KN/m): 35, 50, 65, 80, 100, 120, 140, 160, 180, 200, 250;

Width: 1m – 6m.

3. Technical Data Sheet of PET Woven Geotextile

Item | Specification | ||||||||||

Material | Polyester | ||||||||||

MD(KN/m) | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 |

CD(KN/m) | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 |

Elongation at Break | MD=35; CD=30 | ||||||||||

Width Variation, % | ±0.1 | ||||||||||

CBR Mullen Burst Strength, KN | 2.0 | 4.0 | 6.0 | 8.0 | 10.5 | 13 | 15.5 | 18 | 20.5 | 23 | 28 |

Sieve Size O90(O95) mm | 0.07 ~ 0.50 | ||||||||||

Tearing Strength, KN | 0.5 | 00.8 | 1.1 | 1.3 | 1.5 | 1.7 | 1.9 | 2.1 | 2.3 | 2.5 | 3.0 |

Weight, g/m2 | 140 | 2200 | 260 | 320 | 390 | 450 | 530 | 600 | 680 | 760 | 950 |

Property of PET Woven Geotextile:

1) High strength, low deformation.

2) Durability: steady property, not easy to resolved, air slaked and can keep the original property long term.

3) Anti-erosion: anti-acid, anti-alkali, resists insects and mould.

4) Permeability: could control the sieve size to retain certain permeability.

Application of PET Woven Geotextile

It is widely used in river, coast, harbor, highway,railway, wharf, tunnel, bridge and other geotechnical engineering.

It could meet all kinds of geotechnical projects needs such as filtration, separation, reinforcement, protection and so on.

FAQ:

Questions and Answers:

Q: Can you accept sample order?

A: Yes, we accept samples with little and reasonable charge.

Q: What is your MOQ?

A: Normally, 5000 m2 per order.

Q: What is your delivery time? Can we short it in 7 days or less?

A: 7 days for sample, 20-25 days for mass production.

Q:How about your quality?

A: Try a small order, you will have your own judgment!

- Q:What are the benefits of using geotextile tubes?

- Geotextile tubes offer several benefits, including effective erosion control, dewatering of sediments, and the ability to create stable and durable structures. They are cost-effective, environmentally friendly, and provide a flexible and adaptable solution for various engineering projects. Additionally, geotextile tubes can be easily installed and removed, making them a convenient option for temporary or long-term applications.

- Q:Which version of the material mechanics (author) is suitable for civil engineering this profession?

- According to your own situation and school

- Q:What are the benefits of using geotextile tubes in coastal erosion prevention?

- Geotextile tubes offer several benefits in coastal erosion prevention. Firstly, they provide a cost-effective solution compared to traditional methods like rock or concrete structures. Secondly, these tubes are flexible and can adapt to changing coastal conditions, including wave action and tidal fluctuations. Additionally, geotextile tubes are environmentally friendly as they allow for natural sedimentation and vegetation growth, enhancing habitat restoration. Furthermore, they are easy to install and remove, making them a versatile and temporary erosion control measure. Overall, geotextile tubes offer a sustainable and efficient approach to mitigating coastal erosion.

- Q:What are the specific applications of geotextile mattresses in riverbank stabilization projects?

- Geotextile mattresses are used in riverbank stabilization projects to prevent erosion, control sediment movement, and promote vegetation growth. These mattresses provide a stable base for riparian vegetation, protect the underlying soil from scouring, and filter water to minimize sediment runoff. Additionally, they can be easily installed and adapted to different riverbank conditions, making them a versatile solution for maintaining and protecting riverbanks from erosion.

- Q:Do earthwork products require any special maintenance?

- Yes, earthwork products such as retaining walls or drainage systems may require regular maintenance to ensure their effectiveness and longevity. This can include inspecting for erosion or damage, clearing debris or obstructions, and addressing any issues promptly to prevent further damage. Regular maintenance helps to preserve the functionality and structural integrity of earthwork products.

- Q:How do earthwork products help with site preparation?

- Earthwork products, such as topsoil, fill dirt, and gravel, play a crucial role in site preparation. Topsoil is essential for cultivating healthy vegetation and promoting plant growth. It provides a fertile layer for plants and helps maintain moisture levels in the soil. Fill dirt is used to level uneven terrain, fill holes, and create a stable foundation for construction projects. Gravel, on the other hand, helps with drainage, preventing water accumulation and erosion. Overall, earthwork products contribute to creating a stable, functional, and aesthetically pleasing site for a variety of purposes, from landscaping to building construction.

- Q:Are earthwork products resistant to freeze-thaw cycles?

- Yes, earthwork products are generally resistant to freeze-thaw cycles.

- Q:What are the benefits of using geotextile mats in geotechnical engineering projects?

- Geotextile mats offer several benefits in geotechnical engineering projects. Firstly, they provide effective soil stabilization by preventing erosion and soil movement, thereby enhancing the overall stability of the project. Secondly, geotextile mats act as a filtration barrier, allowing water to pass through while retaining fine particles and preventing clogging of drainage systems. Additionally, these mats are cost-effective alternatives to traditional methods, reducing construction time and labor costs. Moreover, they promote environmental sustainability by minimizing the need for excavation and reducing soil loss. Overall, geotextile mats are valuable tools in geotechnical engineering, improving project durability, efficiency, and minimizing environmental impact.

- Q:Can geosynthetics be used for reinforcement in road construction?

- Yes, geosynthetics can be used for reinforcement in road construction. Geosynthetics, such as geotextiles and geogrids, are commonly used to improve the stability, durability, and performance of roads by enhancing subgrade support, reducing deformation, and controlling soil erosion. They provide additional tensile strength and prevent the mixing of different soil layers, thereby enhancing the overall strength and sustainability of the road structure.

- Q:How do earthwork products contribute to soil stabilization in construction sites?

- Earthwork products such as geotextiles, geogrids, and geocells contribute to soil stabilization in construction sites by providing reinforcement, erosion control, and drainage capabilities. These materials can be used to prevent soil erosion, retain soil particles, and improve overall soil strength. They act as a barrier against water flow, reducing the risk of erosion and maintaining the stability of the soil. Additionally, earthwork products can also facilitate proper drainage, preventing the accumulation of water that can weaken the soil and cause instability. Overall, these products play a crucial role in ensuring the stability and longevity of construction sites by enhancing the soil's ability to withstand various loads and environmental conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Strength Woven Geotextile for Road Construction Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords