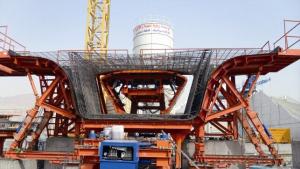

High quality precast concrete bridge beam segmental box girder steel formwork

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 watt

- Supply Capability:

- 5000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Segmental box girder steel formwork

Product Introduction:

With the rapid development of urban rail transit project, the Segmental box girder steel formwork is widely used in viaduct road. It have the advantages of noise-reduction good effect, low building height, high space utilization and good appearance.

With the progress of technology, construction method changes from cast-in-place to precast hoisting. Use double crane lifting or gantry crane lifting to hoisting the Segmental box girder steel formwork .

Specification:

Precast U-Beam formwork structure: outer side formwork, inner formwork, bottom formwork, support lead screw, JACK, work platform, Vibrator, crawling ladder, blanking plate etc.

Main products covers:

U-shaped beam

Segmental beam

Climb mold

Integrated pipe gallery

Automatic Prefabrication culvert

Shaped pier

T-beam

Alien template

Applied formwork Project:

Our products capacity:

More than 3 state grade certificates

More than 40 patents

More than 10 series main products

More than 10 government and project awards

WORKSHOP & EQUIPMENT:

- Q:How to do the foundation beam template

- The main body of each layer of concrete using fixed pump delivery. Before pouring, it is necessary to clear the debris in the template and advance the wet mode, the concrete vibration needs to be timely, coherent, and shall not leak slurry, reinforcement intensive place need to strengthen the vibration, to ensure the concrete density. Concrete vibrator should try to avoid the direct vibration of the template, to prevent the expansion of the joints at the seams, so as to set up the site to inspect the quality of the template.Wall column concrete pouring in place, to prevent the beam, the plate when pouring overflow phenomenon affect the appearance quality, the wall column concrete pouring should be carried out in time for two times to ensure that the structure section size is correct, the founder does not distort deformation.

- Q:The formula for the calculation of beam, concrete and brick

- (1) single beam, the support of the template is not deducted, the end of the template does not increase. Beam length(2) when the beam and beam intersect, the area of the main girder is not deducted.(3) beam, plate connection, beam wall template to plate ping.

- Q:Why is Changshi beam, but also computing to the side or side column beam?How to deduct the overlap area between beam and plate, column and wall, wall and wall

- The connection between the column and the beam and the place where the beam is connected with the beam does not need to be deducted from the area.

- Q:Which part of the middle beam and side beam in the T beam template? Thank you

- The use of T beam highway bridge generally 5 pieces of beam for the span of 1, which is the outermost of the two to become [edge beam]

- Q:What kind of frame beam formwork

- Application of cast in situ concrete formwork beam single beam, continuous beam combination of steel formwork support! But don't forget, scaffolding, templates, and membranes. Specific look at your project and your province of the quota

- Q:The formwork support is a beam template which is connected with both sides of the vertical rod and the force at the bottom of the beam and the force of the vertical wire rod which is arranged below the transverse beam at the bottom of the beam

- This option is not available in the design parametersCan only be used in the calculation of the calculation of the book or the program alone: double fastener!

- Q:How to do irrigation formwork

- For plate 120 H-0.05, the -0.05 here is the elevation of the plate is reduced by 5cm. - drop, + raise. Here the drop and elevation are relative floor elevation.

- Q:What is the demolition order of the construction template

- 1 demolition vertical face template, should be carried out from top to bottom; demolition of the larger span of the beam pillar, should start from the middle, respectively, to the two ends.2 demolition of beams and floor bottom mold, should loosen the wedge or lower bracket, then by block or patch removal

- Q:When the height of the beam is small, the beam of the beam is tied up on the top of the beam formwork; when the beam height is large, the steel bar of the beam is bound on the bottom of the beam. What do you mean?

- When the beam height is small, the steel bar of the beam is tied on the top of the beam template, which means that the steel bar of the beam is lighter than the whole, and the steel bar is integrally arranged in the template after the aerial binding;

- Q:The area of the beam template = (both sides of the high and low beam) * beam lengthWhat do you mean by the two words in the brackets?

- Wall: exterior wall from the upper surface of the floor to the upper surface of the floor, the inner wall is considered to the upper floor (beam) under the surface, within 0.3 square meters of the area of the hole is not deducted, do not increase the side wall template, the use of large formwork when the hole is not deducted

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High quality precast concrete bridge beam segmental box girder steel formwork

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 watt

- Supply Capability:

- 5000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords