High Density SHP Grade Graphite Electrode with Nipples

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Graphite Electrode Description

Topfly Material Co., Ltd.(Topfly Material) is a professional supplier of graphite products, which include graphite electrode, graphite block, graphite scrap, graphite powder and graphite parts. We have complete production lines, which include raw material mixing, forming line, baking line, impregnation equipment, graphitization line and machining and shaping line.

Graphite electrodes, widely used in steelmaking, non ferrous, foundry, casting, silicon industry. According to their level of quality, it can be divided into RP, HP and UHP grade. This item is for UHP grade graphite electrode. Resistivity: ≤6.0ohm, Bulk Density: ≥1.67g/cm3. Diameter is 350-650mm, length is 1800±100mm.

2.Main Features of the Graphite Electrode

(1) Pure quanlity, high carbon content.

(2) Competitive price, we have price advantage for HD grade graphite electrode.

(3) High density ≥1.67g/cm3 and low resistivity≤6.0ohm.

(4) Large quantity in stock, delivery time is within 25 days.

3.Graphite Electrode Images

More products for your reference:

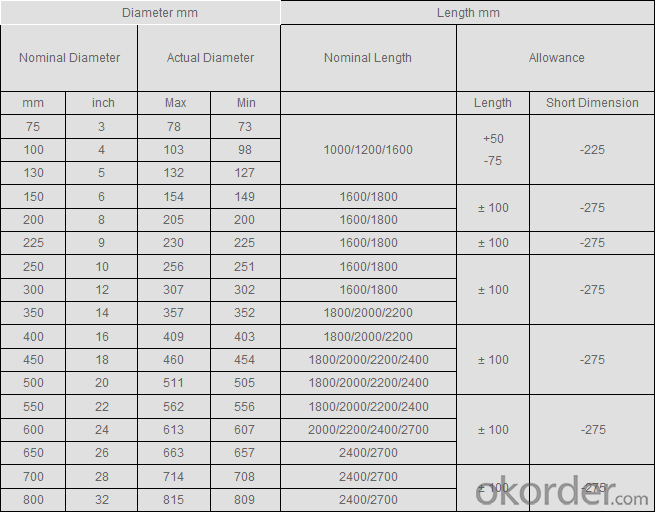

4.Graphite Electrode Specification

5.FAQ

We have organized several common questions for our clients, may help you sincerely:

(1) How to guarantee the quality of the products?

We have established the international advanced quality management system, every link from raw material to final product we have strict quality test; we resolutely put an end to unqualified products material flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(2) MOQ

For trial order, we accept 10 MT.

(3) Payment term

20% deposit, balance against the BL copy; 100% L/C at sight.

(4) How long can we receive the product after purchase?

We have large quantity in stock, and we could machine it to the size you need, so the delivery time is around 25 days after receiving your deposit or L/C.

- Q:The difference between graphite electrode and graphite rod

- Graphite rod for non metal products, as carbon arc gouging cutting process in an essential pre welding cutting supplies, is composed of carbon and graphite with appropriate adhesive, through the extrusion, the temperature of 2200 DEG C after baking rotary plating a layer made from copper, high temperature resistance, good electrical conductivity, is not easy fracture, suitable for metal cutting into required shape.

- Q:Does the silicon carbide heat plant require a fine structure graphite electrode? What kind of graphite products do you need?

- Silicon carbide graphite is very famous for its high hardness and wear resistance. It is generally used in high wear resistance machinery industry and high wear resistant sealing industry.

- Q:Why is the production of one ton of ultra high power graphite electrode requires 1.05 tons of coke?

- Petroleum coke is divided into needle coke and sponge coke and projectile reef, fixed carbon content components of petroleum coke is around 80%

- Q:MITSUBISHI machine graphite electrode processing, how does not accumulate carbon?

- Carbon deposition can cause insufficient combustion of gasoline and cause engine chattering.

- Q:800KVA and 12500 EAF transformer data graphite electrode furnace.

- Graphite project: Project Description: steel furnace and iron smelting furnace, ferrosilicon smelting, electrolytic aluminum and so on, all use large surface graphite electrode.

- Q:What are the skills of hardfacing process for wear-resistant alloy powder blocks?

- The power supply adopts the DC arc welding machine with steep drop characteristic, adopts the positive connection method, the electrode is negative, and the electrode is a high strength spectrum pure graphite rod,

- Q:How about graphite electrode high-temperature oxidation resistant coating?

- Can be used, temperature characteristics of nano composite ceramic coating is more stable, and nano composite ceramic nano high temperature oxidation resistant coatings of different graphite products according to the use conditions, can the temperature of 1600 degrees, forming a dense coating on graphite coated with rust, corrosion, high temperature resistance, oxidation resistance, wear resistance and other properties.

- Q:How to improve the efficiency of graphite electrode milling, please tell me

- The technical development of the high-speed machining center lays the foundation for improving the milling efficiency and quality of the graphite electrode, especially for the milling of the small electrode with complicated shape and thin wall. In the EDM mold processing, the graphite electrode needs to be processed by the high-speed machining center (HSM), so the demand for HSM machine tools is also increasing. But for some time, because of the technological developments in hard steel processing, it seems possible to make graphite electrodes an obsolete technology.

- Q:How to solve the problem of graphite electrode being crushed during electrolysis

- This graphite electrode is so true because it causes gas to expand and disintegrateTantalum electrodes can be solved and not expensive

- Q:Will the concentration of electrolytic sodium sulfite be increased with graphite as electrode?

- Can't。 During electrolysis, there is depletion of sulfite ions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Density SHP Grade Graphite Electrode with Nipples

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches