High Alumina Brick for Steel Refining

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Discription for High Alumina Brick for Steel Refining

CMAX High Alumina Brick for Steel Refining are classified according to alumina content ranging from 48% to 90%.

CMAX High Alumina Brick for Steel Refining are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln,regenerator, etc.

Brief Features for High Alumina Brick for Steel Refining

◆Low thermal conductivity

◆Excellent acid and base slagging resistance

◆High refractoriness

◆Excellent thermal shock resistance

◆Excellent mechanical strength

◆Good spalling resistance and wear resistance.

◆Good corrosion resistance.

◆High-temperature creep rate is quite low.

◆Good volume stability at high temperature.

◆Low bulk density, low thermal conductivity, good thermal insulation performance.

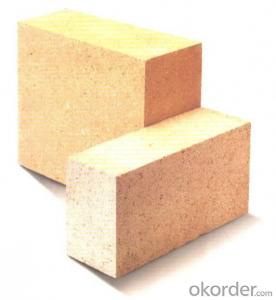

Image/photograph for High Alumina Brick for Steel Refining

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

- Q:What should be used as binder for making high alumina bricks?

- In addition, high alumina micro powder can be used as binding agent, or high alumina micro powder and clay powder are prepared according to a certain proportion, and synthetic mullite is used as bonding agent. With these binders, high alumina bricks without two expansion can be prepared.

- Q:How to distinguish the good or bad of the high aluminum brick?

- In the procurement of high alumina brick, the first color, high quality aluminum brick, brick surface smooth, yellow color pale, four sides equal, no broken angle, no cracks.

- Q:Corundum, high alumina and fireclay refractory difference is what

- Corundum is unknown. The high alumina brick has higher aluminum content than the clay brick, and the temperature resistance is higher than 300 degrees. It is more durable and durable than the clay brick. The production process of high alumina brick is better than that of clay brick. For example, the weight of good clay brick is 3.7kg, and that of high alumina is 4.2kg. Good density. But the price of high aluminum is too high: ordinary clay brick (standard brick example) in 1.1--2.5 yuan / block, high aluminum to 4.5 yuan / block, or even more expensive. The extra high aluminum has reached 5000 tons. Say straight white point is: under the same conditions, clay brick for a period of one year, then the high aluminum for more than three years.

- Q:What are the alloy wear resistance materials?

- Alloy wear-resistant materials from different manufacturers different components in Beijing Naimo company as an example, the following alloy wear resistant material:1: Ni Cr alloy wear-resistant material2: chrome carbide wear-resistant material3: high manganese alloy wear-resistant material4: tungsten carbide alloy wear-resistant material5: nickel tungsten alloy wear-resistant material

- Q:What are the grades of high alumina bricks?

- According to the size of high aluminum brick is divided into: standard brick, special-shaped brick.

- Q:What is fireproof concrete?

- Silicate fireproof heat-resistant concrete using temperature can reach 700 DEG ~800 DEG, the main mechanism of its heat is dehydrated calcium hydroxide silicate hydrates series of cement clinker under high temperature, the calcium oxide and slag and mixing activated silica material in the three and two aluminum oxide and the reaction of anhydrous calcium silicate and anhydrous aluminum acid calcium has strong heat resistance, the fire resistance of concrete is a certain. Such as the use of high alumina bauxite and broken bricks, magnesia brick and magnesia for fireproof heat-resistant concrete materials with the highest using temperature can reach 1100 DEG C.

- Q:High alumina brick 80 with which high aluminum cement?

- In order to maintain a reasonable comprehensive lining, should adopt high quality aluminum refractory mud, such as Sichuan resistance card phosphate refractory mud, refractory clay, high alumina refractory mud PA-80 LN-75, if you use the card volume of Sichuan resistant refractory clay masonry, the effect is better.

- Q:What are the categories of bricks?

- Clay brick materials, cheap, durable, and fire prevention, heat insulation, sound insulation, moisture absorption and other advantages, is widely used in civil engineering. Waste brick can also be used as aggregate of concrete. In order to improve the shortcomings of ordinary clay bricks, such as small, self important and waste of soil, they are developing in the direction of light weight, high strength, hollow and big blocks.

- Q:What is spalling resistant high alumina brick?

- Spalling resistant high alumina brick is a kind of high alumina brick. Antistripping high alumina brick with high grade bauxite and containing Zr02 synthesis as raw material, according to a certain proportion by high pressure molding system in sintering products, products with anti stripping ability, and have the anti erosion potassium, sodium, sulfur, chlorine and alkali salt, low thermal conductivity and other properties that is the transition zone of cement kiln and decomposition of ideal material with remarkable characteristics, the product is good thermal shock resistance, strong ability to adapt to the environment. It is used in the preheating or decomposing furnace, grate cooler and so on.

- Q:What are the requirements for refractory materials in heat treatment furnace?

- Refractoriness is the property of a refractory against high temperature, which means the temperature at which a refractory is softened to some extent after heating, but not its melting point. According to the degree of refractory, refractory materials can be divided into: General refractories, refractory degree is 1580 to 1770 DEG C; advanced refractories, refractory degree is 1770 to 2000 DEG C; special refractory material, refractory degree is greater than 2000 DEG C.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Alumina Brick for Steel Refining

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords