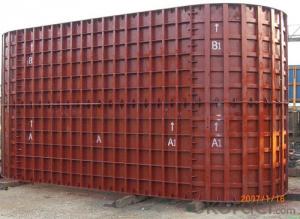

Heavy Steel Formwork for Dam Construction with Anti-Corrosion Paint

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction for Steel Formwork :

Steel Formwork:used in highway,railway,bridge,tunnel and shearing wall,etc.Our company CNBM which is one of the largest State-Owned Enterprises in China which established in 1984 , has gained the confirmation from the specialist of China Architecture Scence Institute, and has been used by many building operation units and has been highly praised.In 2014, the total turnover volume of CNBM exceeds US$410 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises !

Characteristic for Wholly Steel Formwork :

1. High Smooth Surface

2. Convex ling for Edge Rib

3. Specialized Connection Pin for Edge Rib Connection

4. High Stiffness for Steel Surface

5. Light Weight for saving producing cost

6. Fast Separate and Easy transport

7. Recycling using

8. Scientific and Reasonable design to meet different working condition

Parameter and Specification :

Code | Size (mm) | Weight (KG) | Code | Size (mm) | Weight (KG) |

P12021 | 1200*2100*55 | 102.96 | P4018 | 400*1800*55 | 28.3 |

P12018 | 1200*1800*55 | 88.4 | P4015 | 400*1500*55 | 23.8 |

P12015 | 1200*1500*55 | 74.15 | P4012 | 400*1200*55 | 19.1 |

P12012 | 1200*1200*55 | 60.11 | P4009 | 400*900*55 | 14.6 |

P10018 | 1000*1800*55 | 76.01 | P4007 | 400*750*55 | 12.3 |

P10015 | 1000*1500*55 | 63.96 | P4006 | 400*600*55 | 9.95 |

P10012 | 1000*1200*55 | 60.11 | P3018 | 300*1800*55 | 20.7 |

P10009 | 1000*900*55 | 39.32 | P3015 | 300*1500*55 | 17.4 |

P9018 | 900*1800*55 | 70.89 | P3012 | 300*1200*55 | 14 |

P9015 | 900*1500*55 | 59.47 | P3009 | 300*900*55 | 10.7 |

P9012 | 900*1200*55 | 48.03 | P3007 | 300*750*55 | 8.8 |

P7518 | 750*1800*55 | 57.8 | P3006 | 300*600*55 | 7.3 |

P7515 | 750*1500*55 | 48.47 | P3004 | 300*400*55 | 5.46 |

P7512 | 750*1200*55 | 39.16 | P2515 | 250*1500*55 | 15.17 |

P7509 | 750*900*55 | 29.85 | P2512 | 250*1200*55 | 12.24 |

P7507 | 750*750*55 | 24.81 | P2509 | 250*900*55 | 9.32 |

P6018 | 600*1800*55 | 43.1 | P2507 | 250*750*55 | 7.71 |

P6015 | 600*1500*55 | 36.3 | P2506 | 250*600*55 | 6.39 |

P6012 | 600*1200*55 | 31.7 | P2015 | 200*1500*55 | 11.6 |

P6009 | 600*900*55 | 23.9 | P2012 | 200*1200*55 | 9.4 |

P6007 | 600*750*55 | 18.55 | P2009 | 200*900*55 | 7.1 |

P6006 | 600*600*55 | 16.25 | P2007 | 200*750*55 | 5.9 |

P5018 | 500*1800*55 | 36.27 | P2006 | 200*600*55 | 6.39 |

P5015 | 500*1500*55 | 30.15 | P2004 | 200*450*55 | 3.64 |

P5012 | 500*1200*55 | 25.55 | P1515 | 150*1500*55 | 9.5 |

P5009 | 500*900*55 | 20.38 | P1506 | 150*600*55 | 4 |

P5007 | 500*750*55 | 15.48 | P1504 | 150*450*55 | 2.98 |

P5006 | 500*600*55 | 13.58 | P1015 | 100*1500*55 | 7.5 |

Code | Size (mm) | Weight (KG) |

P1012 | 100*1200*55 | 6.9 |

P1009 | 100*900*55 | 4.6 |

P1007 | 100*750*55 | 3.8 |

P1006 | 100*600*55 | 3.1 |

P1004 | 100*450*55 | 2.33 |

E1515 | 150*150*1500 | 15.2 |

E1512 | 150*150*1200 | 12.26 |

E1509 | 150*150*900 | 9.34 |

E1507 | 150*150*750 | 7.77 |

E1506 | 150*150*600 | 6.46 |

E1504 | 150*150*450 | 4.87 |

E1015 | 100*150*1500 | 13.13 |

E1012 | 100*150*1200 | 10.61 |

E1009 | 100*150*900 | 8.07 |

E1006 | 100*150*600 | 5.44 |

Y1018 | 100*150*1800 | 14.56 |

Y1015 | 100*150*1500 | 12.29 |

Y1012 | 100*150*1200 | 9.72 |

Y1009 | 100*150*900 | 7.46 |

Y1007 | 100*150*700 | 6.19 |

Y1006 | 100*150*600 | 5.19 |

Y1004 | 100*150*450 | 3.92 |

J0018 | 50*50*1800 | 4.34 |

J0015 | 50*50*1500 | 3.7 |

J0012 | 50*50*1200 | 2.94 |

J0009 | 50*50*900 | 2.3 |

J0007 | 50*50*750 | 1.9 |

J0006 | 50*50*600 | 1.5 |

J0004 | 50*50*450 | 1.13 |

FAQ :

1. Who are we ?

We , CNBM , are a State-Owned Enterprise which established in 1984 , have 32 years experience ,enjoy high reputation .

2. Our Advantage :

Customized products , we have our own R&D department , we can design the drawing and suggest the suitable solution for your project .

3. Our after-Sales Service :

The international Sales Manager and Engineer can go to your job site for work direction and help you deal with your project .

Factory Photos :

- Q:Can steel formwork be used for projects with aggressive concrete mixes?

- Yes, steel formwork can be used for projects with aggressive concrete mixes. Steel formwork is known for its strength, durability, and resistance to various environmental factors. Aggressive concrete mixes typically contain higher amounts of chemicals such as chlorides, sulfates, or alkalis, which can be corrosive to some materials. However, steel formwork is usually resistant to these aggressive chemical attacks and can withstand the harsh conditions associated with aggressive concrete mixes. It is important to ensure that the steel formwork used is properly coated or treated to enhance its resistance to corrosion and chemical attacks. Regular maintenance and inspection of the formwork are also necessary to identify and address any signs of deterioration or damage. Overall, steel formwork can be a suitable choice for projects with aggressive concrete mixes due to its strength and resistance to chemical attacks.

- Q:What are the common cost implications of using steel formwork in a construction project?

- The utilization of steel formwork in a construction project can result in several cost implications, both positive and negative. One of the common cost implications of employing steel formwork is the higher initial investment required in comparison to other formwork materials like timber or aluminum. Steel formwork typically entails a greater upfront purchase or rental expense, which can elevate the initial costs of the project. Nonetheless, it is crucial to take into account the long-term advantages of steel formwork, since its durability and ability to be reused can offset these initial expenditures. Another cost implication of using steel formwork is the reduction in labor and material costs. Steel formwork is renowned for its robustness and capacity to support heavy loads, permitting larger spans and heights to be accomplished with fewer supports. Consequently, less labor and material are necessary for support structures, resulting in potential cost savings. Moreover, the utilization of steel formwork can facilitate increased construction speed and efficiency, which can translate into cost savings. Steel formwork systems are designed for straightforward assembly and disassembly, enabling faster construction cycles. This can aid in diminishing labor costs and overall project duration, thereby minimizing the impact of inflation and other potential cost escalations. Furthermore, the durability and reusability of steel formwork can contribute to long-term cost savings. Unlike timber or plywood formwork, steel formwork can endure multiple uses without significant deterioration. This extends its lifespan and diminishes the need for frequent replacements or repairs, leading to financial savings on material costs in the long run. However, it is important to acknowledge that steel formwork may necessitate additional expenses for transportation and storage. Steel formwork is heavier and bulkier than alternative materials, which can augment transportation costs. Additionally, proper storage and maintenance are vital to ensure the longevity of steel formwork, which may entail supplementary expenses for cleaning, rust prevention, and storage facilities. To conclude, although there may be higher initial costs involved in employing steel formwork in a construction project, the long-term benefits of durability, reuse, reduced labor, and increased construction speed can outweigh these expenses. A thorough evaluation of the specific project requirements, budget, and timeline is necessary to ascertain whether the cost implications of using steel formwork are advantageous for a particular construction project.

- Q:Can steel formwork be used for both large and small-scale construction projects?

- Yes, steel formwork can be used for both large and small-scale construction projects. Steel formwork is known for its durability, strength, and flexibility, making it suitable for a wide range of construction projects. It can be easily customized and adjusted to meet the specific requirements of both large and small-scale projects. Steel formwork also offers a high level of reusability, which makes it cost-effective for both types of projects. Additionally, steel formwork provides a smooth and high-quality finish to concrete structures, ensuring the desired aesthetic appeal for both large and small-scale construction projects.

- Q:Can steel formwork be used for curved structures?

- Curved structures can indeed make use of steel formwork. Steel is an incredibly versatile and robust material that can be easily manipulated and crafted into various shapes, including those with curves. By utilizing advanced technologies like computer-aided design (CAD) and computer-aided manufacturing (CAM), steel formwork can be specifically tailored to meet the precise needs of curved structures. This allows for increased flexibility and innovation in architectural design, empowering engineers and architects to fashion one-of-a-kind and visually captivating curved structures. Furthermore, steel formwork possesses numerous advantages such as longevity, reusability, and the ability to bear substantial loads. These qualities make it an ideal choice for constructing curved structures that necessitate both structural strength and stability.

- Q:What are the typical maintenance requirements for steel formwork systems?

- The maintenance requirements for steel formwork systems can vary depending on the specific design and usage. However, there are some typical maintenance tasks that should be performed to ensure the optimal performance and longevity of these systems. Firstly, regular cleaning is essential for steel formwork. After each use, the formwork should be thoroughly cleaned to remove any concrete residue or other debris. This can be done using water and a brush or high-pressure cleaning equipment. It is important to remove all traces of concrete to prevent build-up and potential damage to the steel. Additionally, inspection of the formwork is crucial to identify any signs of wear or damage. Regular inspections can help detect any issues early on and prevent them from escalating into more significant problems. This includes checking for cracks, dents, or bent components that may compromise the formwork's integrity or affect its alignment. Furthermore, lubrication of movable parts is necessary to ensure smooth operation. Steel formwork systems often have adjustable components like clamps, connectors, or locking mechanisms that may need lubrication to prevent friction and facilitate easy adjustments. Applying a suitable lubricant to these parts will help maintain their functionality and prevent them from becoming stuck or difficult to operate. It is also important to store the steel formwork properly when not in use. This typically involves storing the components in a dry and well-ventilated area to prevent corrosion. Moisture can cause rust and deterioration of the steel, so it is crucial to keep the formwork away from areas with high humidity or direct exposure to water. Lastly, regular maintenance should include periodic reconditioning or repair of any damaged or worn-out parts. This may involve replacing worn-out components, reinforcing weak areas, or welding any cracks or fractures. Performing these repairs promptly helps maintain the structural integrity of the formwork and ensures its safe and reliable operation during subsequent uses. Overall, by following these typical maintenance requirements such as cleaning, inspection, lubrication, proper storage, and timely repairs, the steel formwork systems can be kept in excellent condition, extending their lifespan and ensuring their performance and safety in construction projects.

- Q:What are the considerations when designing steel formwork for architectural features?

- When designing steel formwork for architectural features, there are several considerations that need to be taken into account. Firstly, the formwork design should align with the desired aesthetic of the architectural feature, ensuring that it complements the overall design intent. Additionally, the formwork needs to be structurally sound and capable of supporting the weight and forces exerted by the concrete during pouring and curing. It is important to consider the ease of assembly and disassembly of the formwork to ensure efficiency in construction. Furthermore, the formwork design should allow for proper placement of reinforcement and any necessary inserts or embedded items. Finally, considerations such as cost, durability, and maintenance should also be factored in to ensure the longevity and functionality of the steel formwork.

- Q:How does steel formwork impact the overall construction productivity?

- The numerous advantages of steel formwork make it significantly impact overall construction productivity. Firstly, steel formwork is highly durable, allowing for multiple uses and cost-effectiveness in construction projects. Unlike timber formwork, it does not warp or shrink, ensuring consistent dimensions and reducing the need for frequent repairs or replacements. This durability eliminates the delay caused by formwork maintenance or replacement, saving time and money. Additionally, steel formwork offers superior strength and stability, enabling the construction of larger and more complex structures. Its rigid nature ensures it can support heavy concrete loads without deformation or collapse. This not only enhances construction site safety but also speeds up the pouring of concrete and reduces the need for additional support structures, facilitating the construction process. Moreover, steel formwork is highly versatile and easily customizable to meet specific project requirements. It can be easily assembled, disassembled, and repositioned, making it efficient in various construction phases. This flexibility saves time and effort by eliminating the constant construction of new formwork for different parts of the structure. Reusing steel formwork also reduces material waste, further improving productivity. Furthermore, steel formwork provides better surface finishes compared to other systems. Its smooth and rigid surface ensures high-quality finishes, reducing the need for additional finishing work such as plastering or leveling. This saves time and improves overall construction productivity. In conclusion, steel formwork enhances construction productivity through its durability, strength, stability, versatility, and high-quality finishes. Its long-lasting nature, ease of use, and ability to withstand heavy concrete loads contribute to reduced downtime and increased efficiency on construction sites. Steel formwork is essential for enhancing construction productivity.

- Q:Can steel formwork be used for curved or irregularly shaped structures?

- Yes, steel formwork can be used for curved or irregularly shaped structures. Steel formwork is highly flexible and can be easily customized to match the desired shape or form of the structure. Its strength and durability make it suitable for various construction projects, including those that involve unique or unconventional designs.

- Q:How does steel formwork handle different concrete surface finishing options?

- Steel formwork offers versatility and durability in creating concrete structures, effortlessly accommodating various concrete surface finishing options. The sleek and inflexible nature of steel formwork permits the application of diverse finishing techniques to the concrete, resulting in a plethora of textures and appearances. A smooth finish is a commonly chosen concrete surface finishing option, achievable by employing well-maintained and properly aligned steel formwork. The steel formwork's smooth surface translates onto the concrete, yielding a polished and refined finish often sought after for architectural and decorative purposes. Alternatively, a textured finish is an option that can be achieved by utilizing steel formwork imprinted with patterns or textures. The concrete adopts the texture of the steel formwork, resulting in a visually captivating and distinctive surface. Moreover, steel formwork facilitates the application of various coatings and treatments to the concrete surface. For instance, the steel formwork can be coated with a release agent prior to pouring the concrete, facilitating a smooth finish and effortless removal of the formwork. Additionally, the steel formwork can be treated with a curing compound or sealant to enhance the durability and appearance of the concrete surface. In summary, steel formwork serves as a dependable and adaptable solution for accommodating diverse concrete surface finishing options. Its robustness and rigidity enable the creation of smooth, textured, and coated finishes, empowering architects and contractors to achieve the desired aesthetic and functional requirements of the concrete structure.

- Q:How does steel formwork affect the overall sound insulation of a building?

- Steel formwork does not directly affect the overall sound insulation of a building. However, it can indirectly impact sound insulation by influencing the type and quality of materials used for insulation purposes. The choice of materials for sound insulation, such as the selection of appropriate insulation panels or acoustic barriers, will have a greater impact on the overall soundproofing performance of a building.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Heavy Steel Formwork for Dam Construction with Anti-Corrosion Paint

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords