Graphite Electrode Manufacturer/Graphiteelectrode for Arc Furnace/Graphite Electrode for Edm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc. The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to 700mm. Our products own the following characteristics: low electric resistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanicalshock, high mechanical strength, high machining accuracy.

Graphite Electrodes Features:

RP HP UHP Graphite Electrode

1.Dia:40-600mm or1.6"-24"

2.Length:250-2400mm or10"-96"

3.Nipples:3TPI,4TPI

4.ISO9001:2008

Graphite Electrodes Application:

An increasing proportion of global steel is made using electric arc furnaces, and the electric arc furnace itself is getting more efficient and making more steel per tonne of electrode

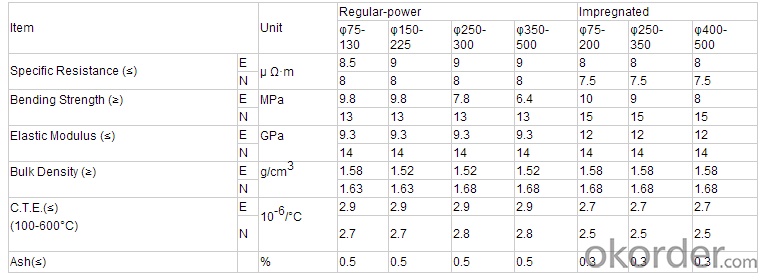

Graphite Electrodes Specifications

1.Good electrical conductivity

2.High resistance to thermal shock

3.High mechanical strength

Grades:RP, RPI, HP, SHP, UHP

Technical data:

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q:The reason why graphite is used as electrode

- The graphite has good conductivity and thermal conductivityThe conductivity of graphite is one hundred times higher than that of ordinary non-metallic minerals. Heat conductivity exceeds steel, iron, lead and other metal materials. The coefficient of thermal conductivity decreases with increasing temperature, and even at extremely high temperatures, the graphite becomes hot.

- Q:Classification, uses and manufacturers of graphite electrodes

- Classification of graphite electrodes:(1) common power graphite electrode (RP), (2) high power graphite electrode (HP), (3) quasi ultra high power graphite electrode (SHP), (4) ultra high power graphite electrode (UHP) Note: poly carbon classification method

- Q:I remember the more lively metal, the electron?

- C is a salt solution of copper metal because copper is first reduced to a single element on a graphite electrode.Moreover, the addition of dilute sulfuric acid has a H2 emission, then a H of the previous metal.

- Q:Jiqiu conductive graphite electrode, how to compare with copper is relatively large resistance value?

- This is not a good estimate of the sheet graphite resistance after 5mm

- Q:How long is the graphite electrode machining cycle?

- The dust produced in the processing of graphite electrode is relatively large, the possible intrusion to the machine tool guide screw and spindle, which requires a corresponding machining device of graphite graphite dust machine, sealing better, because the graphite toxic.

- Q:The future of graphene

- Energy storage and new display areas. Graphene has excellent conductivity and transparency. As a transparent conductive electrode material, graphene has a good application in touch screen, liquid crystal display, energy storage batteries and so on. Graphene is considered to be the most potential alternative to indium tin oxide manufacturing in touch screen manufacturing, and Samsung, SONY, Hui Rui, 3M, Dongli, Toshiba and other leading enterprises have made key research and development layout in this field. Researchers at the University of Dezhou, Austen, used KOH to chemically modify graphene to form a porous structure, resulting in a storage density of ultracapacitor near the lead acid battery. Michigan Technological University scientists have developed a unique honeycomb structure of three-dimensional graphene electrode, photoelectric conversion efficiency of 7.8%, and low price, is expected to replace platinum in solar cells applications. Toshiba Co developed graphene and silver nanowires composite transparent electrode, and achieved a large area.

- Q:What's the use of carbon?

- Common power graphite electrode. Allows the use of current density of less than 17A/ cm 2 graphite electrode, mainly used for steelmaking, smelting silicon, yellow phosphorus and other ordinary power furnace.

- Q:Graphite can be used in acid towers in chemical plants because of graphite

- A graphite electrode coated with an antioxidant protective layer (graphite electrode, antioxidant). The utility model has the advantages of forming a protective layer capable of conducting electricity and resisting oxidation at high temperature, reducing electrode consumption (19%~50%) during steelmaking, prolonging the service life of electrodes (22%~60%), and reducing the electric energy consumption of electrodes.

- Q:Please senior doubts. The graphite electrode is used in the mold cavity In what case is graphite processing taken?

- Because of the great loss of graphite electrode in finishing, it is not suitable to be used as finishing electrode material. Because of the small coefficient of thermal expansion of graphite, it can also be used as a big electrode material in perforation processing.

- Q:Can Naiduo high temperature graphite

- Graphite cut gasket is from pure graphite plate drilling or cutting and it has good corrosion resistance, high / low temperature, compression elasticity and high strength good, complex geometric gasket circular is widely used in all kinds of pipes, valves, pumps, pressure vessels, heat exchanger, and condenser generator, air compressor, exhaust pipe, refrigerator etc..

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Graphite Electrode Manufacturer/Graphiteelectrode for Arc Furnace/Graphite Electrode for Edm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords