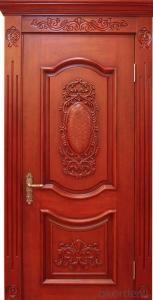

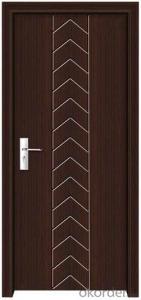

GOOD QUALITY WOODEN DOOR used for Interior room

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 3000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Wooden door

ISO9001&Green environmental protection product

wooden door

1) Dimensions (for doorleaf):

2000 x 700/800/900mm

Or customized for inquery

2) Door thickness: 40mm

3) Wall thickness: Not more than 340mm

4) Material:

A) Inner: Honeycomb paper

B) Wood keel: Chinese fir

C) Exterior: MDF

D) Surface: wood Veneer and paint

E) Edges: Chinese fir wood

5) Hinge: 180 degree visible hinge

6)Packing: Foam plastic pad + PP bag and export outer box

7)MOQ: 1*20FC

8)Loading QTY: 230PCS/20FC; 480PCS/40HQ

9) Delivery port: Ningbo or Shanghai

- Q:Walnut wood door can be painted into a white open paint?

- Walnut texture comparison fine Ni is more suitable for the closure of the paint like Ash and red oak texture rough Kau Shan pattern is more suitable for doing paint as white rub gold and white silver is quite fashionable

- Q:How to distinguish between wooden doors and solid wood doors?

- Wooden doors are generally made of walnut, cherry, maple, teak, oak, ash and other raw materials such as wood, the whole door is the same material, looks elegant. Solid wood door is very broad definition, but also includes the original wooden door, but generally also refers to the use of fir, pine these low-grade wood to do, there may be several kinds of wood stitching made. These two doors are relative to the plywood door, but it should be easy to distinguish.

- Q:My home years ago to install the original wooden doors, deformation shrinkage and indoor temperature is too high?

- Raw materials may be dry, is wet wood, and later dry, on the deformation

- Q:My house is old-fashioned house is a wooden door closed with a gap next door people cooking special spicy straight to my family do not know how to solve the sadness of my death

- Then you in your yard on the shelf a small pan, ah, pour a small amount of oil to the pepper pepper are poured into the cooking has been, and get the fan to his house into a fan, and that you have a big hatred.

- Q:Will the wooden doors and windows can be used to effectively seal to prevent dust from entering?

- To the hardware store to see if there is no doors and windows seal or to get some water and putty and rubber are very similar to the small cracks easy to fill, and then set the rubber to try!

- Q:How to deal with the shrinkage of the original wooden door

- Solution 1 First of all to be clear, shrinkage and cracking is different. Shrinkage is the thermal expansion and contraction of the physical properties of wood, mainly in the door to help the door between the core board, with the Department of the expansion joints caused by the expansion of the door core plate to open the paint exposed white; cracking is due to high moisture content, Poor process caused by, is a quality problem. The natural properties of the logs determine its variability, made after the product, a certain degree of contraction is inevitable, as if the bridge, the road should be left with the same shrinkage, the higher the water content of the greater shrinkage, the general wooden structure Basically can not solve the problem. Wooden door for the characteristics of these logs, the source control and process control to grasp the way to solve: 2 source control: wooden doors on the one hand selection of stable performance of imported timber, the use of raw materials are first through the international advanced steam drying, stereotypes technology, And then the second drying treatment, the wood moisture content control between 8% -12%, and then according to the product used in the classification of the region. General hardwood tree drying cycle should be about 25 days, some drying cycle and even up to 40 days -50 days. 3 process control: by improving the production process, the original anti-shrinkage anti-cracking treatment technology, the first to do after the paint assembly, set the shrinkage joints, with the joints to strengthen the strength of taps and so on, and truly anti-shrink, anti-cracking, Solid wood door contraction cracking problems.

- Q:I would like to ask myself to call the furniture factory to do the original wooden door? Also listen to others that the original wooden door will be deformed, right?

- Mainly to see the material used well, for a long time will be a little bit

- Q:Kitchen and restaurant between the sliding door with aluminum door or look good with wood doors

- I would suggest you use aluminum-magnesium alloy, plus two pieces of art glass, is also an effect landscape

- Q:Composite doors and wooden doors can make the same color? Question added: composite door paste wood door veneer. More

- If it is skin paste, then it can be the same

- Q:What is the difference between solid wood doors and wooden doors?

- Wooden doors are made of wood, but they are usually made of wood, but they are usually made of pure wood, or blockboard (thin wood veneer ) Made. Generally from the wood grain, stubble can be resolved. Another pure wood color good resolution, poor paint to distinguish. Before you can paint, it's better to distinguish. Sedimentation is also one of the ways to distinguish. The logs are lighter than the gluing. Weiyang plate enthusiastic answer, hoping to help you!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GOOD QUALITY WOODEN DOOR used for Interior room

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 3000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches