GATE VALVE SOCKET ENDS NON-RISING STEM RESILIENT SEATED DUCTILE IRON DN50 - DN300

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Standard or Nonstandard: | Standard | Structure: | Gate | Pressure: | Normal Pressure |

Power: | Hydraulic | Material: | Casting | Temperature of Media: | Normal Temperature |

Media: | Water | Port Size: | DN50~DN300 | Place of Origin: | China (Mainland) |

Model Number: | DIN3352/SABS664 | Brand Name: | CMAX | Surface: | Powder coating/Acid pickling/Paint |

Test: | 100% water pressure |

Packaging & Delivery

Packaging Details: | Standard export package or as per your requirement |

Delivery Detail: | 20-25 Days, depends on the demand quantity |

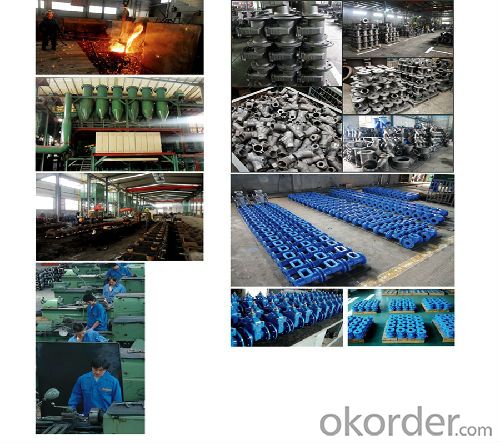

Details of Socket End Non-Rising Stem Gate Valve:

1) Design and Manufacture Standards:

a. DIN3352

b. BS5163

c. ANSI B16.34

d. API60

e. API6D and Russian standard

2) Material:

a. Cast Iron (GG20, GG25)

b. Ductile Iron (GGG50)

c. Carbon Steel, WCB

d. Stainless steel

3) Sealing:

a. Rubber

b. Metal

4) Operation:

a. Hand-wheel

b. Driving head

c. Electric actuator

5) Media:

Water, Oil etc.

6) Working pressure:

a. 1.0Mpa

b. 1.6Mpa

c. Class150LB-2500 LB

7) Working dimensions: DN50-DN800

8) Temperature: Normal Temperature

9) Coating:

a. Fusion Bonded Epoxy Powder Coating

b. Akzo Nobel Powder Coatings

- Q:What is the difference between the cut-off valve and the gate valve?

- When opening and closing, the valve core and valve seat sealing surface always contact and rub each other, so the sealing surface is easy to wear, the valve is close to shut down, the pressure difference between the pipe is very large, so that the sealing surface wear more serious.Gate valve and stop valve advantages and disadvantages:Valve is the advantages of small flow resistance, the media can flow in two directions, but there are tall, complex structure, sealing surface easy to wear shortcomings. The flow resistance of the gate valve is 3-5 times that of the gate valve. Open and close to shut down in order to seal the valve, the valve is completely closed when in contact with the sealing surface, the sealing surface wear is very small, because the flow of the main actuator with large valve should pay attention to adjust the torque control mechanism.

- Q:Why can't the pressure measuring point be set at the two ends of the gate valve when measuring the resistance loss of the gate valve?

- Because of the unsteady flow of fluid near the inlet and outlet of the valve, the measured data cannot be obtained relatively accurately.

- Q:Generally, how big is the diameter of the installation flange plate gate valve?

- Under normal circumstances:Flanged gate valves for piping over DN50,DN50 (below) can be made of wire or gate valves, or flanged gate valves (flanged valves or welded gate valves)

- Q:What is the difference between the copper gate valve and the ordinary material gate valve?!

- The material of general gate valve is cast iron, and the copper gate valve should be used in special requirement.

- Q:What does valve qz45x - 10q mean?

- Crown valve pressWhat does Q stand for? I'm not sure. It's probably made of ductile iron"Z" means "gate valve"4 represents flange connection5 represents the dark bar (1 represents the Ming pole)X stands for rubber seal and soft seal10q stands for 10 pressure

- Q:Why? God, can you explain to me in detail why?

- The exit of the general pump is the first soft connection (shock absorber), followed by the check valve, and then the partition valve (such as butterfly valve, gate valve, cut-off valve, etc.), this is not the final answer.The question is interesting, and no corresponding information has been found in the relevant standards. We have also discussed the related issues, but differences of opinion is relatively large, the advantages of 1, first installed check valve installed after the valve or butterfly valve, check valve, can be protected, especially in a parallel pump, when the pump does not start, another pump starts when the impact force is gate valve or butterfly valve bear, disadvantages: gate valve or check valve who will protect? There have been a case of butterfly valve is broken. 2, first installed gate valve or butterfly valve installed after the check valve, advantages: can protect the butterfly valve or gate valve, the impact on the check valve to bear. Disadvantages: check valve who will protect, check valve by pressure difference switch, if the high pressure high pressure pipe, pump, if the flow is not stable, so check valve will repeatedly switch, will affect the check valve life. Personal opinion: check valve, check valve performance now have changed, many are using the slow closing check valve, so the impact force is two aspects to bear, because exports are not fully open the valve or butterfly valve, so you can put in check after the gate valve or butterfly valve valve. If not the slow closing check valve installed in the valve or the best after the butterfly.

- Q:What's the meaning of the gate valve model z41x 16Q?

- Gate valve (Z) flange connection (4) wedge type single gate (1) rubber soft seal (X) -16 pressure) (Q)

- Q:What does gate valve Z44T-10-200 code mean?

- The meaning of the model is standard, the landlord himself to check the JB/T308 standard, Baidu library some, and is free to download:JB/T 308-2004 valve type method of preparation clear EditionHttp://wenku.baidu /view/5f798850ad02de80d4d84036.htmlZ = gate valve4 = connection: flange4 = structure form: double gateT = sealing surface material: Copper10 = nominal pressure: 1.0MPa, followed by no letters indicate body material: Cast Iron200 = nominal path: DN200

- Q:What is the difference between Z41X gate valve and Z45X gate valve?

- All flange soft sealing gate valve, but 41X is Ming bar, 45X is dark pole

- Q:Is the axial force and torque of the wedge gate valve the same?

- See where you are, it is better to compare it: wedge type single gate valve features: a structure more flexible, gate valve is simple, sealing performance better than flexible gate valve or double gate valve.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GATE VALVE SOCKET ENDS NON-RISING STEM RESILIENT SEATED DUCTILE IRON DN50 - DN300

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords