Galvanized Steel Drywall Profiles Ceiling Channels

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

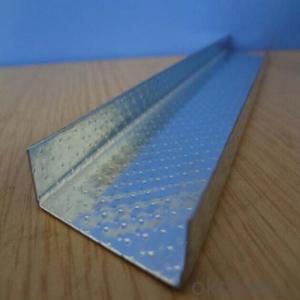

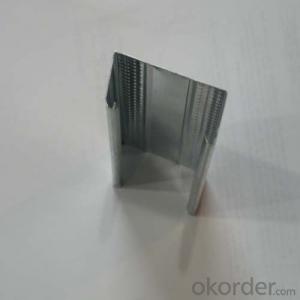

Regular Specification for Partition Wall System

1. Stud size: 50 x 35mm, 50 x 40mm, 70 x 35mm, 70 x 40mm, 75 x 35mm, 75 x 45mm, 100 x 45mm

2. Track size: 50 x 30mm, 70 x 35mm, 75 x 35mm, 75 x 40mm, 100 x 40mm

3. Length: 2. 7mm, 2. 8mm, 2. 9mm, 3. 0mm

4. Thickness: 0. 35mm, 0. 4mm, 0. 45mm, 0. 5mm, 0. 6mm

All sizes and shapes of steel channels are available

Ceiling Channel for ceiling system

1. Supporting channel: 38 x 12mm, 38 x 20mm, 50 x 15mm, 60X27mm

2. Covering channel: 50 x 19mm, 60x 27mm ,35x22mm

3. Length: 2. 7mm, 2. 8mm, 2. 9mm, 3. 0mm

4. Supporting channel: 0. 5mm, 0. 6mm, 0. 8mm, 1. 0mm, 1. 2mm

5. Covering channel: 0. 35mm, 0. 4mm, 0. 45mm, 0. 5mm, 0. 6mm

All sizes and shapes of steel channels are available

Corner bead & wall angle

U angle 24x19x13x0.4/0.45/0.5mm

L angle 25x25x0.4/0.45/0.5mm

All sizes and shapes of steel channels are available

Advantages

1. Raw material is high quality hot dipped zinc galvanized steel strip, good fireproof and heat insulation, waterproof, antirust, anticorrosive ,and high durability.

2. High quality raw material guarantees the light steel keel of life and good performance of construction.

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 3weeks after receiving of downpayment

Picture

- Q:Light steel keel wall Why use gypsum board to do grass-roots level?

- Longgang wall: light steel keel is a new type of building materials, with the development of China's modernization, in recent years has been widely used in hotels, terminals, passenger stations, stations, theaters, shopping malls, factories, office buildings, old buildings Building renovation, interior decoration, roof and other places. Light steel keel wall with light weight, high strength, good fire resistance, versatility and easy installation characteristics, to adapt to shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, Easy to deformation and so on.

- Q:I would like to have a toilet in the house, bathroom with mineral wool board cut off or light steel keel gypsum board line?

- You said the mineral wool board and gypsum board can not be used because they are not waterproof tide will be deformed Recommended ceiling with PPC or aluminum gusset plate is to do with the wall with calcium silicate board is the cement board on the line waterproof paint with a little better is no problem

- Q:In Shanghai 75 partition wall light steel keel 0.6 what price now

- The general keel material costs 34 or so manual 15 that you look at the offer

- Q:Light steel keel wall circuit how to wear pipe

- 1, to C-type vertical keel on the threading hole as the basis, first determine the direction of the upper and lower ends of the keel, try to align the threading hole. Vertical keel length size, should be measured according to the size of the scene. The premise is to ensure that the vertical keel can be along the ground, along the long keel slot slide. 2, light steel wall vertical keel installation spacing, according to the actual width of the panel size and wall structure design may be. 3, vertical keel installed in place, should ensure that the vertical. Door and window openings should be taken double row of vertical keel reinforcement. When the design requirements for the steel connection, the vertical keel and the edge along the top keel of the fixed, the application of self-tapping screws or shaft rivets to connect. sixth,

- Q:How to install damping sound insulation felt

- 1, along the wall laying sound insulation felt, seam at the pressure seam processing; ???? 2, the installation of vibration keel, wedge around 600mm; keel gap filled with cotton; ???? 3, vibration-proof keel installed on the noise board (two-layer board clip insulation felt, sheet and sound insulation stitch treatment)

- Q:What is the decoration of the wall? Lightweight bricks Or light steel keel frame?

- Well, I think so, I found two companies were quoted, the price is almost, but the listed materials are not the same.

- Q:How to do woodworking partition wall, with door

- Wooden skeleton should use specifications for 40 mm × 70 mm red, from pine. The spacing of the keel should take into account the size of the panel, usually between 450 and 600 mm If there is a door, both sides should establish a vertical keel. The dragon keel should be connected with the lordel open rod, the window on the bottom and the top of the door should be installed along the horizontal keel installed along the ground, along the top wood Leng, the corners should be stretched into the brick at least l20 mm, To ensure that the partition wall and the original structure of the wall connected firmly.

- Q:75 series of light steel keel wall double-sided double-layer 12 thick plaster board filled with sound insulation noise can reach the number of decibels

- Light steel keel gypsum board system is usually double-sided wall structure, that is, "plate - keel (cavity) - plate" structure, each side of the wall board for the single or double gypsum board, Light steel keel. In order to obtain better sound insulation effect, in the cavity filled with rock wool board or glass wool.

- Q:Light steel keel partition wall construction process is what

- Light steel keel partition wall - → installation of the door hole box - → installation along the top keel and along the keel → vertical keel sub-file - → installation of vertical keel - → installation of horizontal keel card - → installation panel - Sewing practice - → face layer putty paint (or paint).

- Q:Use light steel keel to do the shelf, install the glass partition wall, this process is feasible? How about construction?

- Have to do, nothing can not, but not a good idea. The feeling of the glass is bright and transparent. Light steel keel specifically suitable for installation, the concealed keel with transparent glass display will be what effect.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Steel Drywall Profiles Ceiling Channels

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords