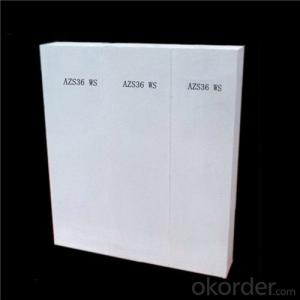

Fused Cast Alumina White Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Fused Cast Alumina White Refractory Bricks

| Place of Origin: | Henan, China (Mainland) | Shape: | Brick, brick or as buyer's request | Material: | Castable |

| SiO2 Content (%): | 16 | Al2O3 Content (%): | 51 | MgO Content (%): | other |

| CaO Content (%): | other | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | other |

| SiC Content (%): | other | Model Number: | AZS33 white brick | Brand Name: | ZHENJIN |

| Color: | white | Model: | AZS33 | Applied: | Ceremic and Glass |

| ZrO2: | 32.0~36.0 | Certification: | ISO 9001 | Work Life: | 12 months |

| OEM: | Acceptable white brick | Sample: | Free | Origin: | Xinmi,Zhengzhou,China |

Packaging & Delivery

| Packaging Details: | wooden pallet+ carton box+plastic shrink wrap white brick |

| Delivery Detail: | 20 days after get payment |

Electro Fused Cast Brick white brick--Applied in Ceremic and Glass Kiln

Features:

1.Strong volume stability at high temperatures

2.Good thermal shock resistant

3.Wear resistance

4.Chemical corrosion resistance

Applications:

Mainly used in Glass and Ceremic Kiln.

Dominate Products Introduction:

Steel Fiber Reinforced Special Brick - Patent Product!

----For Kiln Mouth to enforce the crushing strength with good thermal shock resistance

Magnesioferrite Spinel brick------Chrome Free

Mullite-Sic Composite brick

Direct-bonded Magnesia-Chrome brick

Magnesia-Aluminum Spinel brick -----Chrome Free

Mullite-Sic Resistance brick

High Strength Alkali-Resistant brick

Antistripping High Alumina brick

Magnesia-Aluminum-Chrome Composite brick

Low-Chrome Direct-Bonded Magnesia-Chrome brick

Main Equipment Show:

2,500 tons automatic hydraulic presses

FAQ:

1. What’s the payment?

Usually T/T, others could be discussed.

2. When will you deliver the goods?

The delivery time will be determined according to the quantity of the order.

3. Do you provide samples?

Yes, samples are available.

4. How are your products’ quality?

The products will be strictly inspected before shipment, so the quality could be guaranteed.

5. Do you accept OEM?

Yes, we can do OEM.

- Q:What's the weight of the refractory bricks?

- Light weight brick 1 to 1.7 kilograms; heavy clay superscript brick weighs 3.75 kilograms; light 30 plates 0.79 kilograms; light 40 plates, 1.05 kilograms

- Q:Outside wall tile (whole body smooth surface has small hole split brick) has cement pollution, with what product cleaning (cement, mortar, cleaning agent)?

- Tile has a long period of cement pollution, a variety of weak acid cleaning can be removed, such as oxalic acid, acetic acid and so on, of course, the use of special cleaning agent is perfect. But the cost is higher.

- Q:What are the specifications for bricks?

- Thecompressive node as a new type of building energy-saving wall materials, which can be used for masonry walls, but also has good thermal properties, in line with the construction of the building module, reduce the loss in the process of construction, improve work efficiency; the hole rate reached more than 35%, can reduce the weight of the wall, save the foundation engineering cost. Compared with common sintered porous brick, it has the characteristics of heat preservation, heat insulation, light weight, high strength and high construction efficiency. The product is made of shale as raw material. It is produced by high vacuum extrusion molding machine and one yard firing process

- Q:What are kiln bricks?

- Refractory materials are generally divided into two kinds, namely unshaped refractory and shaped refractory. Unshaped refractory castable is also called, is composed of a variety of aggregate or aggregate and one or more adhesive powder particles, and must use one or more liquid with stirring, has strong liquidity. Refractory materials generally refers to the shape of a refractory brick, standard rules, can also according to need to be cut when the temporary processing.

- Q:Is the wall around the fire area using a firewall? What's the difference between a fireproof brick and a regular brick?

- Fire bricks burn well!!In fact, the firewall does not necessarily have to use the so-called "fire brick", but to see the brick fire limit!240, the fire limit seems to be 4 hours, 370 I do not remember clearly, fire codes have, you see, do not think so naive!

- Q:Just what is in the furnace material?

- It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q:What is brick power, half brick power and full brick power difference?

- All brick power up to 500 watts up and down. The internal circuit is tight and heating, the device has good adhesion, the circuit is more advanced, and the efficiency is high, so it can achieve small size and high power.

- Q:Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- It is in the production process, zirconium corundum bricks are likely to cause pollution.

- Q:Can the fire clay be reused?

- According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, ordinary brick, specific rotation. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature.

- Q:How are qualitative and qualitative refractories understood?

- Unshaped refractory products, referred to as bulk loading, are made at the place of use for the required shapes and for heat treatment, such as castable, ramming, projection, spray, refractory clay, etc..

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fused Cast Alumina White Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords