Fiberglass Geogrid with Low Elongation Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

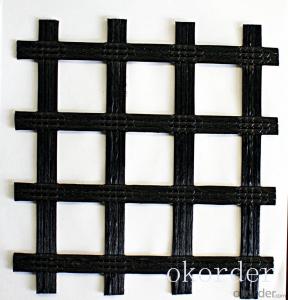

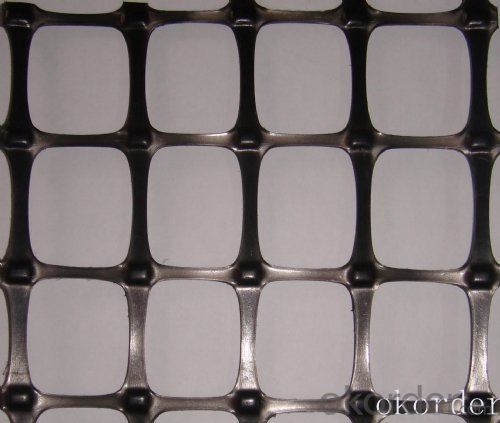

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is composed of fiberglass filaments that are coated with an inorganic sizing agent

Temperature Resistance (Centigrade): -100~290

Surface Processing: Modified asphalt or Polymer and self adhesive

Packing: With PE bagsType:

Geogrids

Material:

Fiberglass

Coating:

asphalt

feature:

High flexibility and large range

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Engineering effect of steel plastic geogrid

- Steel plastic geogrid:When the geogrid is used in the soft ground treatment, the location and the number of the geogrid should be determined according to the geological condition.When the filling height is greater than 4m, the geogrid to meet the minimum requirements of industry standards, the vertical and horizontal limit tension should not be less than 20kN/mWhen the filling height is between 3-4m, the vertical and horizontal tensile force of geogrid is not less than 40kN/mWhen the filling height is less than 3m, the geogrid vertical ultimate tension is not less than 50 kN/m, the elongation is less than 4%, the proposed use of GSZ60-60 type geogrid when the geogrid embankment excavation combination should be used when the bidirectional geogrid is not less than 40kN/m, should adopt the GSZ60-60 type of GeogridAs for the old road widening old road junction, referring to the method of reconstruction and extension of the use of Grid: where the fill height is larger than 3 meters away from the roadbed, roadbed cap at 20 cm of paving plastic composite grille, with vertical (vertical line direction) limit tension is greater than or equal to 60kN/m, the transverse (parallel line direction) ultimate tension greater than or equal to the plastic composite geogrid 20kN/m, elongation is less than or equal to 4%.

- Q:How do geogrids improve the performance of geotextile containers?

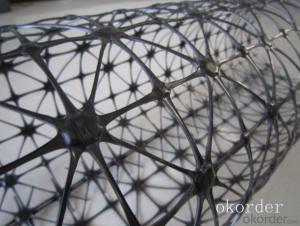

- Geogrids improve the performance of geotextile containers by providing additional strength, stability, and reinforcement to the structure. By incorporating geogrids into the design, geotextile containers become more resistant to stress, deformation, and settling. The geogrids effectively distribute loads across the container's surface, preventing excessive strain on the geotextile material and maintaining the integrity of the structure.

- Q:Can geogrids be used in coastal protection?

- Yes, geogrids can be used in coastal protection. Geogrids are commonly used in coastal engineering projects to stabilize and reinforce soil or rock structures, such as seawalls, revetments, and breakwaters. They help to prevent erosion and provide extra strength and stability to withstand the forces of waves, tides, and storms. Geogrids are effective in enhancing coastal protection measures and can be a valuable component of coastal engineering solutions.

- Q:Are geogrids suitable for reinforcing steep slopes?

- Yes, geogrids are suitable for reinforcing steep slopes. Geogrids are commonly used in slope stabilization and reinforcement applications due to their high tensile strength and stability. They can effectively distribute and transfer the load of the soil, reducing erosion and preventing slope failures.

- Q:Are geogrids suitable for use in soft soil conditions?

- Yes, geogrids are suitable for use in soft soil conditions. Geogrids are typically made from high-strength materials such as polyester or polypropylene, which provide reinforcement and stabilization to weak or soft soils. They can effectively distribute loads, improve soil stability, and prevent soil erosion. Geogrids are commonly used in various civil engineering applications, including road and railway construction, embankments, and retaining walls, where soft soil conditions are present.

- Q:What are the different materials used to manufacture geogrids?

- Geogrids are manufactured using various materials such as polyester, polypropylene, high-density polyethylene (HDPE), and fiberglass. These materials offer different strengths, durability, and chemical resistances, allowing geogrids to be customized for various applications in civil engineering and construction projects.

- Q:What are the differences between geogrids and geopipes?

- Geogrids and geopipes are both types of geosynthetics used in various construction and civil engineering applications, but they serve different purposes. Geogrids are typically made of high-strength polymer materials and are used to reinforce soil and provide stability to the ground. They are commonly used in road construction, retaining walls, slopes, and embankments to distribute loads and prevent soil erosion. Geogrids are characterized by their open-grid structure, which allows for soil interlocking and improved load distribution. On the other hand, geopipes are flexible conduits made of plastic materials and are primarily used for drainage purposes. They are designed to collect and transport excess water or other fluids from the soil or structures. Geopipes can be perforated or solid, depending on the specific drainage requirements of the project. They are commonly used in applications such as subsurface drainage, landfills, and stormwater management systems. In summary, while both geogrids and geopipes are geosynthetics used in construction, geogrids are used for soil reinforcement and stability, while geopipes are used for drainage purposes.

- Q:What is the effect of geogrid aperture size on performance?

- The effect of geogrid aperture size on performance is that a smaller aperture size generally leads to better performance. This is because a smaller aperture size allows for better soil confinement and interlocking, resulting in improved stability, load distribution, and overall performance of the geogrid. A larger aperture size, on the other hand, may lead to reduced confinement and interlocking, potentially compromising the geogrid's performance.

- Q:What are the types of geogrid, respectively, what role?

- Glass fiber geogrid features:The product has the characteristics of high strength, low elongation, high temperature resistance, high modulus, light weight, good toughness, corrosion resistance, long service life, can be widely used in the old cement pavement and airport runway maintenance, dams, river, slope protection, bridge pavement engineering field enhancement processing, can give the pavement reinforcement and reinforcement to prevent rutting, fatigue crack of pavement, hot and cold crack and the expansion of reflection crack, and can disperse the bearing capacity of pavement and prolong the service life of the pavement, high tensile strength and low elongation, no long-term creep, high physical and chemical stability, thermal stability, fatigue cracking, rutting resistance, cracking resistance at low temperature delay, reduce the reflection crack.

- Q:How much is the horizontal overlap length of the steel plastic geogrid

- The double lap length is 50cm, and the steel nails. Geotextile lap length is 50cm to 1m

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Geogrid with Low Elongation Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords