Fiberglass Geogrid with High Tensile Strength Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Geogrids

Place of Origin:

Anhui, China (Mainland)

Brand Name:

CMAX

Model Number:

Biaxial

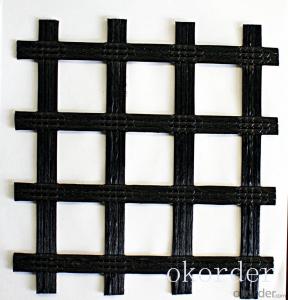

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is composed of fiberglass filaments that are coated with an inorganic sizing agent

Geogrid protects channel slopes, provides resistance and stability, protecting this object from erosion. Additional advantage is drainage along channels. Geogrid application considerably reduces losses, connected with fall of ground, landslides and deformation of slopes.Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Classification and application of polyethylene geogrid?

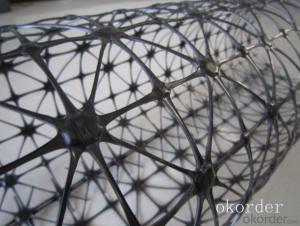

- A grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid

- Q:How much cheaper than steel reinforced plastic geogrid

- Specifications of different prices, the general specification of 4 to 6.5 square.

- Q:Can geogrids be used in stabilization of mine tailings ponds?

- Yes, geogrids can be used in the stabilization of mine tailings ponds. Geogrids are often employed to reinforce and stabilize soil, preventing erosion and promoting the overall stability of the area. In the case of mine tailings ponds, geogrids can be used to enhance the integrity of the pond's walls and base, ensuring that the containment structure remains secure and prevents any leakage or environmental hazards associated with mine tailings.

- Q:What is the effect of moisture on geogrid performance?

- Moisture can have both positive and negative effects on geogrid performance. On one hand, moisture can enhance the interlock between the geogrid and the surrounding soil, improving its overall stability and load-bearing capacity. This is particularly beneficial in clayey or cohesive soils where moisture helps to increase the soil's strength and reduce its potential for settlement. On the other hand, excessive moisture can lead to the loss of geogrid strength due to hydrolysis or chemical degradation, especially in certain polymer-based geogrids. Additionally, waterlogged conditions can increase the likelihood of soil erosion, reducing the effectiveness of the geogrid in retaining soil particles. Therefore, while some moisture is generally beneficial, proper drainage and moisture control are crucial factors to consider for optimal geogrid performance.

- Q:Are geogrids suitable for use in railway ballast reinforcement?

- Yes, geogrids are suitable for use in railway ballast reinforcement. Geogrids provide stabilization and reinforcement to the ballast layer, improving its strength and preventing deformation under heavy loads. They distribute the load more evenly, reducing the risk of settlement and track misalignment. Additionally, geogrids enhance the overall performance and longevity of the railway track by minimizing maintenance and repair needs.

- Q:What is the meaning of 80 in geogrid TGSG80

- 80 per meter of tensile yield strength is more than 80KN/M

- Q:What type of geogrid is CATTXDJ?

- The geogrid grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid

- Q:What are the limitations of geogrids?

- Geogrids have a few limitations that need to be considered. Firstly, they are not suitable for all types of soil. They work best in cohesive soils and may not be as effective in non-cohesive or sandy soils. Secondly, geogrids have limited resistance to chemical degradation, so they may not be appropriate in environments with high chemical exposure. Lastly, geogrids are not designed to withstand heavy loads or provide significant structural support on their own, so they should be used in conjunction with other reinforcement techniques for optimal performance.

- Q:As well as how to fill out the form, thank you!! Urgently

- Do you need a test report for a two-way geogrid

- Q:How do geogrids help in reducing the risk of settlement of structures?

- Geogrids help in reducing the risk of settlement of structures by providing reinforcement and stability to the soil. They are placed within the soil layer to distribute and transfer the load more evenly, thereby reducing the potential for settlement. By increasing the soil's strength and load-bearing capacity, geogrids help prevent excessive settlement and improve the overall stability and longevity of the structures.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Geogrid with High Tensile Strength Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords