FC93 Calcined Anthracite CNBM Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | 25kgs/50kgs/1ton per bag or as buyer's request |

Delivery Detail: | Within 20 days after receiving corect L/C |

Feature

All of our goods are made in the best quality of world famous Tianjin. All of our products are with High carbon, Low ash, low sulphur, Low Moisture.

Usage

The Calcined Anthracite Coal/Gas Calcined Anthracite Coal/Carbon Raiser is mainly used in steelmaking in electrical stove, screening water, shipbuilding sandblast to remove rust. It can reduce the cost of steelmaking effectively by replacing the traditional petroleum coke of carburant.Also can improve the Carbon content in steel-melting and Ductile iron foundry.

Specifications

Calcined Anthracite

Fixed carbon: 90%-95%

S: 0.5% max

Size: 0-3. 3-5.3-15 or as request

PARAMETER UNIT GUARANTEE VALUE | |||||

F.C.% | 95MIN | 94MIN | 93MIN | 92MIN | 90MIN |

ASH % | 4MAX | 5MAX | 6MAX | 7MAX | 8MAX |

V.M.% | 1 MAX | 1MAX | 1.5MAX | 1.5MAX | 1.5MAX |

SULFUR % | 0.5MAX | 0.5MAX | 0.5MAX | 0.5MAX | 0.5MAX |

MOISTURE % | 0.5MAX | 0.5MAX | 0.5MAX | 0.5MAX | 0.5MAX |

Size can be adjusted based on buyer's request.

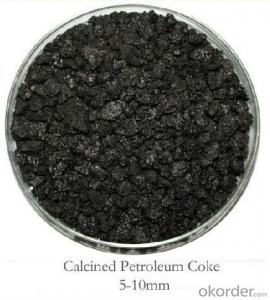

Picture

- Q:What are the main factors that affect the strength of carbon fibers?

- The main factors affecting the strength of carbon fibers arePAN precursorPreoxidationcarbonizationGraphitizationsurface treatmentCoilingcarbon fibre

- Q:How is carbon used in the water treatment process?

- Carbon is used in the water treatment process in a variety of ways. One common method is through the use of activated carbon, which is highly porous and has a large surface area. This allows it to effectively adsorb and remove impurities from water. Activated carbon is often used in the form of granules, pellets, or blocks in water treatment facilities. It can be added to the water during different stages of the treatment process. For example, during the initial filtration stage, activated carbon can be used to remove particles, such as sediment and chlorine byproducts, that can affect the taste and smell of the water. Additionally, activated carbon is effective in removing organic compounds, such as pesticides, herbicides, and industrial chemicals, that may be present in the water. These compounds can be harmful to human health if consumed, so the use of activated carbon helps to ensure the water is safe for drinking. Another way carbon is used in water treatment is through the process of carbonation. This involves the injection of carbon dioxide gas into the water, which helps to lower its pH level. Carbonation is often used in the treatment of alkaline water sources, as it helps to neutralize the water and make it more suitable for consumption. Overall, carbon plays a crucial role in the water treatment process by effectively removing impurities and improving the quality of drinking water. Its adsorption capabilities make it a valuable tool in ensuring that water is safe and healthy for consumption.

- Q:What is carbon black ink?

- Carbon black ink is a type of ink that contains carbon black pigment as its main component. Carbon black is a fine powder made from carbon, which is produced by incomplete combustion of hydrocarbons. In the ink industry, carbon black is commonly used as a pigment due to its intense black color and ability to provide good opacity and UV resistance. Carbon black ink is widely used in various applications such as printing, writing, and drawing. It is commonly found in ballpoint pens, fountain pens, markers, and printer inks. The ink's high concentration of carbon black pigment ensures a deep, solid black color when applied on paper or other surfaces. One of the advantages of carbon black ink is its durability. It has excellent lightfastness, meaning it resists fading or discoloration when exposed to light over time. This is particularly important in applications where long-lasting or archival quality ink is required, such as in art or document preservation. Additionally, carbon black ink has good water resistance and adhesion properties, making it suitable for use on various substrates, including paper, cardboard, and plastics. Its high viscosity ensures smooth and consistent ink flow, allowing for precise and consistent writing or printing. Overall, carbon black ink is a reliable and versatile type of ink that offers intense black color, excellent durability, and good adhesion properties. Its widespread use in various writing and printing applications is a testament to its quality and reliability.

- Q:How is carbon used in the production of diamonds?

- Carbon is used in the production of diamonds through a process called high-pressure high-temperature (HPHT) synthesis. In this method, pure carbon is subjected to extremely high pressures and temperatures, replicating the conditions found deep within the Earth's mantle where natural diamonds form. By applying these conditions, carbon atoms rearrange and bond together, resulting in the formation of synthetic diamonds.

- Q:How can Dungeon Fighter Online's superior furnace rock carbon be obtained?

- Bought in cash. You can go to the mall to have a look.

- Q:What is sintered carbon?

- Sintered carbon is generally used as a filter element, and also of good quality, but very few, most of which are of poor quality.Sintering is the process in which powder or powder compacts are heated to a temperature below the melting point of the basic component and then cooled to room temperature at a certain rate and speed. The result of sintering is bonding between the powder particles, increasing the strength of the sintered body, and changing the aggregate of the powder particles into agglomerates of grain to obtain the desired physical or mechanical properties of the product or material.The sintering process refers to the processing program and the sintering process system selected according to the characteristics of the feedstock. It has a direct and important influence on the production and quality of sinter production.

- Q:Method for making carbon fiber board

- Method for making carbon fiber sheet:1, first determine the thickness of the plate to be made2 calculate the required number of plies according to the thickness3, and then according to 0 degrees, 45 degrees, 90 degrees, -45 degrees in the order of stacking.4, and then molding it!Now carbon fiber board, in fact, many in the middle are entrained with some glass fiber cloth, of course, there are all carbon, a little more expensive!

- Q:What are the consequences of increased carbon emissions on political stability?

- Increased carbon emissions can have significant consequences on political stability. One of the main consequences is the exacerbation of environmental challenges and natural disasters. As carbon emissions contribute to global warming, the frequency and intensity of extreme weather events such as hurricanes, droughts, and flooding increase. These disasters can lead to displacement of communities, destruction of infrastructure, and loss of lives, all of which can have a destabilizing effect on societies. Moreover, the economic impact of increased carbon emissions can also create political instability. As climate change affects agriculture, water resources, and energy production, it can lead to economic disturbances, unemployment, and rising food prices. These economic hardships can fuel social unrest, protests, and even conflicts, particularly in countries that heavily rely on these sectors for their livelihoods. Additionally, the consequences of increased carbon emissions can exacerbate existing social and political tensions. Climate change often disproportionately affects vulnerable populations, such as communities in developing countries or marginalized groups. This inequality can aggravate social inequalities, increase social unrest, and lead to political instability as marginalized communities demand action and justice. Furthermore, the global nature of climate change necessitates international cooperation and agreements to effectively address the issue. However, increased carbon emissions can strain diplomatic relations, particularly between countries that have differing views on climate action. Disagreements over carbon reduction targets, carbon trading mechanisms, and financial contributions can lead to diplomatic tensions and hinder global cooperation, which may consequently impact political stability. In conclusion, increased carbon emissions have far-reaching consequences on political stability. From environmental challenges and natural disasters to economic disturbances and social tensions, the consequences of carbon emissions can strain societies and governments. To ensure political stability, it is imperative that global efforts are made to reduce carbon emissions and mitigate the impacts of climate change.

- Q:How does carbon impact the availability of renewable energy sources?

- Carbon impacts the availability of renewable energy sources in a number of ways. Firstly, carbon emissions from the burning of fossil fuels contribute to climate change, which is a significant threat to the availability and sustainability of renewable energy sources. The increased frequency and intensity of extreme weather events caused by climate change can damage renewable energy infrastructure, such as wind turbines and solar panels. Secondly, carbon-intensive industries, such as coal mining and oil extraction, can limit the growth and development of renewable energy technologies. These industries have historically received substantial subsidies and support from governments, which can hinder the progress of renewable energy by diverting resources and investment away from cleaner alternatives. Furthermore, carbon emissions contribute to air pollution, which can have negative impacts on the efficiency and performance of renewable energy systems. For example, air pollution can reduce the amount of sunlight reaching solar panels or obstruct wind flow to turbines, thereby decreasing their energy output. Additionally, the reliance on carbon-based energy sources creates a significant market competition for renewable energy. Fossil fuels often have lower costs due to their established infrastructure and economies of scale, making it challenging for renewable energy sources to compete on a cost basis. This can limit the availability and accessibility of renewable energy options, particularly in developing countries where fossil fuels are often the cheaper and more readily available option. To address these challenges, it is crucial to reduce carbon emissions through transitioning to renewable energy sources and implementing policies that incentivize their adoption. By reducing carbon emissions, we can mitigate the impacts of climate change on renewable energy infrastructure and create a more conducive environment for the development and deployment of clean energy technologies.

- Q:What is carbon black rubber?

- Carbon black rubber is a type of rubber that contains carbon black as an additive. Carbon black is a finely divided form of carbon, produced by the incomplete combustion of hydrocarbon fuels. It is added to rubber compounds to improve its mechanical properties, such as tensile strength, abrasion resistance, and resilience. The carbon black particles are dispersed within the rubber matrix, providing reinforcement and enhancing its durability and performance. Carbon black rubber is commonly used in the production of tires, conveyor belts, gaskets, seals, and various automotive and industrial rubber products.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FC93 Calcined Anthracite CNBM Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches