epoxy glass cloth products

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 800 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

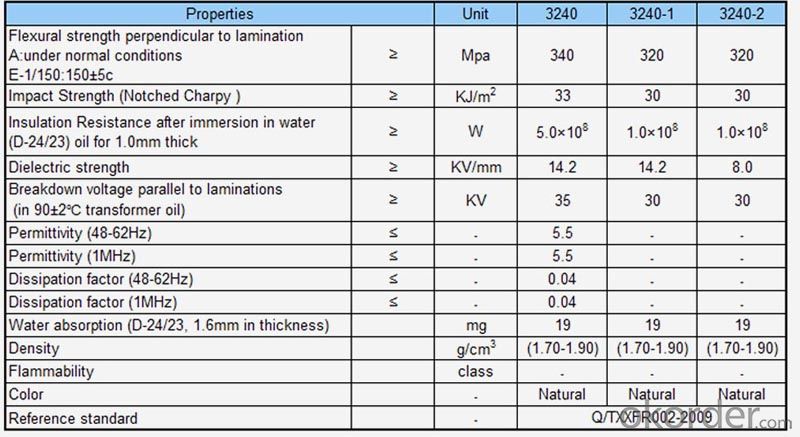

Laminate Type ◆ 3240 G10 G11 FR-4 FR-5 ◆ Thickness:0.5mm-90mm ◆ Size:1000×1200mm 1000×2000mm 1000×2400mm Rod/Tube Type ◆ 3721 3722 3723 3724 3725 3840 3841 3520 3526 3640 ◆ Diameter:6mm 8mm 10mm-200mm ◆ Length:1000mm | |

| 3240 * Temperature grade: B glass (130℃) * Color: nature, red, green, black * Thickness: 0.5-80mm * Size: 1020x2040mm | 3240-1 & 3240-2 * Temperature grade: B glass (130℃) * Color: nature,yellow * Thickness: 0.5-80mm * Size: 1020x2040mm |

| |

| F880A F881A * Temperature grade: B glass (130℃) * Color: nature, green * Thickness: 0.5-80mm * Size(mm): 1020x1220 1020x2040 1220x2470 | F882A F883A * Temperature grade: F glass (155℃) * Color: nature, green * Thickness: 0.5-80mm * Size(mm): 1020x1220 1020x2040 1220x2470 |

- Q:How do glass fiber textiles resist puncturing?

- Glass fiber textiles resist puncturing due to their unique properties and construction. Firstly, glass fiber textiles are made from fine strands of glass fibers that are woven together to form a strong and durable fabric. These fibers are incredibly thin, typically less than a tenth the diameter of a human hair, which allows for a high density of fibers in the fabric. This high density provides a strong barrier against punctures. Additionally, glass fibers are known for their high tensile strength. Tensile strength refers to the ability of a material to resist pulling forces without breaking. Glass fibers have an exceptional tensile strength, which means they can withstand a significant amount of force without tearing or puncturing. Furthermore, glass fiber textiles are often coated with a protective layer or resin. This coating further enhances their resistance to puncturing. The coating acts as an additional barrier, increasing the fabric's durability and preventing sharp objects from penetrating the surface. Moreover, glass fiber textiles are known for their excellent dimensional stability. This means that they do not stretch or shrink when subjected to external forces. This property helps to maintain the fabric's integrity and prevents it from weakening or tearing, even under stress. Overall, the combination of the fine strands of glass fibers, high tensile strength, protective coating, and excellent dimensional stability make glass fiber textiles highly resistant to puncturing. They offer a reliable and durable solution for applications that require protection against sharp objects or potential punctures.

- Q:What are the different types of glass fiber textiles?

- There are several different types of glass fiber textiles that are commonly used in various industries and applications. Some of the most common types include: 1. Woven Roving: This type of glass fiber textile is made by weaving multiple strands of glass fibers together in a crisscross pattern. It is known for its high strength and stiffness, making it suitable for applications that require structural support, such as boat and aircraft construction. 2. Fiberglass Cloth: Fiberglass cloth is a lightweight and flexible glass fiber textile that is commonly used for insulation, reinforcement, and repair purposes. It is often used in the construction industry for reinforcing concrete and in the automotive industry for repairing fiberglass components. 3. Chopped Strand Mat (CSM): Chopped strand mat is made by randomly dispersing short strands of glass fibers onto a continuous mat. It is commonly used in the production of composite materials, such as fiberglass-reinforced plastics (FRP), due to its excellent strength and dimensional stability. 4. Non-woven Fabrics: Non-woven glass fiber textiles are made by bonding glass fibers together using heat, chemicals, or mechanical processes. These textiles are often used for filtration, insulation, and soundproofing applications due to their high porosity and excellent thermal and acoustic properties. 5. Knitted Fabrics: Knitted glass fiber textiles are made by interlocking loops of glass fibers together. They are known for their flexibility and stretchability, making them suitable for applications that require a form-fitting or conformable material, such as protective clothing and sports equipment. Overall, the various types of glass fiber textiles offer different characteristics and properties, allowing them to be used in a wide range of applications across industries such as construction, automotive, aerospace, and manufacturing.

- Q:How are glass fiber textiles used in the medical industry?

- Glass fiber textiles are used in the medical industry for various purposes. One of the key applications is in wound care. Glass fiber textiles, often in the form of dressings or bandages, are used to cover and protect wounds. These textiles have excellent properties such as high absorbency, breathability, and flexibility, which make them ideal for wound dressings. They also provide a protective barrier against bacteria and contaminants, reducing the risk of infections. Glass fiber textiles are also used in the manufacturing of medical devices and equipment. For instance, they are used as reinforcement materials in orthopedic casts, splints, and braces. The high strength and flexibility of these textiles ensure the stability and support needed for proper immobilization and healing of fractures or injuries. In addition, glass fiber textiles find applications in surgical procedures. They are used as surgical drapes, gowns, and masks to provide a sterile environment and prevent the spread of infections during surgery. These textiles are lightweight, resistant to liquids and chemicals, and have low linting properties, making them suitable for use in sterile environments. Furthermore, glass fiber textiles are employed in the production of prosthetic limbs. They are used to create a strong and lightweight framework for the prosthetic, ensuring durability and comfort for the patient. Overall, glass fiber textiles play a crucial role in the medical industry by providing essential solutions for wound care, medical device manufacturing, surgical procedures, and prosthetics. Their unique properties make them a reliable choice for ensuring patient safety, promoting healing, and improving the overall quality of healthcare.

- Q:How do glass fiber textiles contribute to impact strength?

- Glass fiber textiles contribute to impact strength by providing reinforcement to the materials they are incorporated into. The glass fibers are known for their high tensile strength, which means they are able to resist forces that try to stretch or pull them apart. When these fibers are woven into a textile, they create a strong and durable framework that can withstand impact and distribute the force evenly across the material. The interlocking nature of the glass fibers in the textile also helps to absorb and disperse the energy generated from an impact. When a force is applied to the material, the fibers act as a barrier, preventing the crack or fracture from spreading further. This helps to minimize the damage caused by the impact and increases the overall impact strength of the material. Furthermore, glass fiber textiles are lightweight and flexible, making them suitable for use in a wide range of applications. Their ability to enhance impact strength while maintaining their integrity makes them ideal for reinforcing various materials, such as composites, plastics, and even concrete. This allows manufacturers to create stronger and more durable products that can withstand impacts and stresses without compromising their structural integrity. In summary, glass fiber textiles contribute to impact strength by providing reinforcement, absorbing and dispersing energy, and enhancing the overall durability of materials.

- Q:What are the advantages of using glass fiber textile?

- There are several advantages of using glass fiber textile in various applications. Firstly, glass fiber textile is known for its high strength-to-weight ratio. It is a very strong and durable material, capable of withstanding high levels of stress and strain. This makes it ideal for use in industries where strength and resilience are crucial, such as construction and automotive manufacturing. Secondly, glass fiber textile is highly resistant to heat and fire. It has a high melting point, which allows it to maintain its structural integrity even at elevated temperatures. This makes it a popular choice for applications that involve exposure to heat or fire, such as insulation materials and protective clothing. Additionally, glass fiber textile is highly resistant to chemicals and corrosion. It does not react with most chemicals, making it a suitable choice for applications where exposure to corrosive substances is common, such as in the chemical or marine industry. Moreover, glass fiber textile is an excellent electrical insulator. It does not conduct electricity, making it safe to use in electrical applications where insulation is critical, such as in electrical wires or circuit boards. Furthermore, glass fiber textile is lightweight and flexible. It can be easily molded or woven into various shapes and forms, allowing for versatile applications. Its flexibility also makes it easier to handle and install in different settings. Lastly, glass fiber textile is non-toxic and environmentally friendly. It does not release harmful substances into the environment and is recyclable. This makes it a sustainable choice for applications where environmental impact is a concern. Overall, the advantages of using glass fiber textile include its high strength, heat resistance, chemical resistance, electrical insulation properties, flexibility, and environmental friendliness. These properties make it a valuable material in numerous industries and applications.

- Q:Are glass fiber textiles resistant to stretching over time?

- Yes, glass fiber textiles are generally resistant to stretching over time due to their inherent strength and stiffness. Their unique composition and interlocking structure make them highly durable and resistant to elongation, ensuring they maintain their shape and integrity even with prolonged use.

- Q:What are glass fiber textiles?

- Glass fiber textiles, also known as fiberglass textiles, are fabrics made from fine strands of glass fibers. These fibers are highly durable and lightweight, making them suitable for a wide range of applications. They are produced by first melting glass and then extruding it through tiny holes to create the fibers. These fibers are then spun into yarns or woven into fabrics. Glass fiber textiles offer several advantages. They have high tensile strength, meaning they can withstand heavy loads without breaking or stretching. They are also resistant to heat, chemicals, and moisture, making them ideal for use in harsh environments. Additionally, glass fiber textiles are non-flammable and do not emit toxic fumes when exposed to fire. These textiles are commonly used in various industries. In construction, they are used as reinforcement materials in concrete, providing additional strength and durability to structures such as bridges, roads, and buildings. They are also used as insulation materials, helping to regulate temperature and reduce energy consumption in buildings. In the automotive industry, glass fiber textiles are used for manufacturing lightweight and fuel-efficient components such as car bodies, bumpers, and interiors. They are also used in the production of aerospace parts, electrical appliances, and sports equipment. Furthermore, glass fiber textiles are utilized in the field of fashion and home decor. They are used to create fabrics that are lightweight, breathable, and resistant to wrinkles. These fabrics are commonly used in clothing, upholstery, curtains, and bedding. In summary, glass fiber textiles are fabrics made from glass fibers that offer high strength, durability, and resistance to heat, chemicals, and moisture. They are used in a wide range of industries for various applications due to their versatile properties.

- Q:What are the different forms of glass fiber textile?

- The different forms of glass fiber textile include glass fiber yarns, glass fiber rovings, glass fiber fabrics, glass fiber mats, and glass fiber tapes.

- Q:Are glass fiber textiles resistant to chemical reactions?

- Glass fiber textiles are known for their general resistance to chemical reactions. They are produced by spinning molten glass into fibers, resulting in a chemically inert material that does not interact with most chemicals. These textiles find extensive use in industries like chemical and petrochemical, where protection against chemical corrosion is essential. Nevertheless, it should be mentioned that some aggressive chemicals may gradually affect glass fiber textiles. Thus, it is advisable to refer to chemical compatibility charts to confirm their suitability for specific chemical environments.

- Q:Can glass fiber textiles be used in high-temperature applications?

- Yes, glass fiber textiles can be used in high-temperature applications. Glass fibers are known for their excellent thermal resistance properties and can withstand high temperatures without undergoing significant degradation or loss of structural integrity. This makes them suitable for various high-temperature applications, such as insulation materials in furnaces, ovens, and kilns. Glass fiber textiles can also be used in the production of protective clothing or materials that require resistance to heat and fire, such as firefighting suits, welding blankets, and thermal insulation covers. Additionally, glass fiber textiles are often used in the aerospace and automotive industries, where they are exposed to high temperatures generated by engines or other heat sources. However, it is important to note that the specific type and quality of glass fiber textiles should be chosen based on the specific temperature range and requirements of the application to ensure optimal performance and safety.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

epoxy glass cloth products

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 800 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords