Environment-protection Heat Insulation EPS Cement Sandwich Panel for Prefab House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | standard packing with film attached to the surface and seaworthy |

| Delivery Detail: | about 15 days after the deposit if the quantity below 500 tons |

Specifications

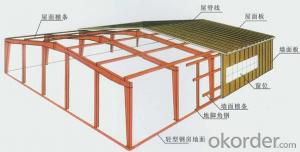

Sandwich Panel / Laminboard

1.metal thickness:0.2-0.6mm

2.RW thickness:50/75/100/150/200mm

3.effective width:950/1150mm

Sandwich Panel / Laminboard

Product Description

Sandwich Panel / Laminboard | |

Steel Thickness | 0.23~0.5 mm |

Panel thickness | 50/75/100/125/150/200 mm |

Effective width | (1) 950mm ---for roof (2) 950 / 1150mm---for wall or ceiling |

Length | According to customer's request, less than 11.8m |

Materials | Inner is rock wool sandwich ,two sides is Galvanized Color steel sheet Rock Wool Sandwich Panel, Glass Wool Sandwich Panel, EPS Sandwich Panel, PU Sandwich Panel |

Structure | three layers: (1)upper layer is steel sheet, (2)the inner layer is rock wool (3)bottom is also steel sheet |

Rockwool density | 110-120(kg/m³),etc Normal is:6kg,8kg/12kg,16kg/m3 |

color | White grey or blue |

Parts | Steel line for easy connect one by one Film covering in order to protect the steel of panels |

lifetime | 15~20 years |

Character | Light in weight, heat insulation, fire-proof and waterproof, environmental |

Use | various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums ,etc |

Technology

Steel sheet | |||

Base steel sheet | Color steel | ||

Thickness | 0.4-0.8mm | ||

Galvanized coating | Hot galvanizing, Cold galvanizing | ||

Coating material | PE,HDP, SMP and PVDF | ||

Coating thickness | More than 20 micrometer | ||

Color | Grey white, Navy, Silvery Grey and other RAL color | ||

Sandwich material | |||

Thermal blanket material | PUR/PIR | ||

Material density | 40+/-5kg/sq.m. | ||

Percentage of close area | More than 96% | ||

Temperature resistance | -185°C—120°C | ||

Heat conductivity coefficient | Less than 0.021w/sq.m.k | ||

Adhesive strength | More than 0.09Mpa | ||

Compressive strength | More than 0.15Mpa | ||

PU composite board | |||

The arrest | Alant-Ribbing-Ripplet-Arc | ||

Length | No restrictions | ||

Width | 960-1000mm | ||

Thickness | 50/75/100/150/200mm | ||

Packaging & Shipping

Package | Craft paper or wooded pallet |

Delivery time | Within 7-15 days after your prepaid |

Payment terms | T/T ,L/C at sight |

- Q:Sandwich panels and Malacca ecological board what is the difference

- Man can pipe the plastic tube can be directly within the tube to detect the actual deformation value

- Q:How does the wall rock wool sandwich panel be installed?

- All the components are axially connected and the mechanical properties are good , The connection is reliable, the composition of the scaffolding integrity is good, there is no loss of fasteners Construction of the bowl button steel pipe scaffolding from the steel pipe pole, bar, bowl buckle joints and other components 粻 Fu Gang Huang 蕺 number reported copper stem expansion The basic structure and erection requirements and fastener steel scaffolding similar to the difference lies mainly in the bowl buckle joints Bowl buckle joints are made up of the bowl buckle, the next bowl buckle, the bar connector and the bowl buckle limit pin and so on In the pole on the welding under the bowl buckle and bowl buckle on the limit pin, the bowl will be inserted into the pole Weld the plug on the cross bar and the diagonal bar When assembling, insert the crossbar and diagonal bar into the lower bowl, press and rotate the bowl buckle, and use the limit pin to fix the bowl buckle

- Q:Color steel sandwich panels and color steel plate What is the difference

- Excuse me, where are you in? Indoor insulation is generally made of "polystyrene foam board", the general thickness is 2..3 cm thick, you can understand clearly, in the end is how thick the foam board (when playing screw holes, can be found is thick thick foam board) The There is that you can use .7 inside the expansion screw, to the hardware store to find can match. You can also use welding, then a long screw, is also very simple.

- Q:How the exterior of the house is made of rock wool color steel sandwich panels

- Construction, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, Erecting outside the scaffolding materials expected ribs of the late section of the dwarf light dog chupu count, template support frame, shelf safety operation technology. Zibu type construction fastener, by the two holes in the diameter of the child is significantly different, the female fastener riveting, two fasteners on the lower cover are steel stamping parts, cover, under the cover with ribs , The upper and lower cover of the middle part of the arc inward convex, the arc-shaped convex surface and the upper and lower cover on both sides of the same cylindrical surface, the child, the female fastener nut on the same size. The fastener is used to build construction scaffolding, building fence, planting greenhouses, etc., can be connected to different diameter pipe, can be rotated angle, wide range of applications, and the fastener weight, bending strength and good steel, , Easy to use.

- Q:Are sandwich panels suitable for food kiosks?

- Sandwich panels are indeed appropriate for food kiosks. They have gained significant popularity in the construction industry due to their durability, insulation properties, and ease of installation. These panels consist of two external layers, typically constructed from metal, and a core material, such as polyurethane foam or rockwool, which offers outstanding thermal insulation. To meet food safety regulations, food kiosks necessitate a hygienic and clean atmosphere. Sandwich panels provide a smooth, non-porous surface that is simple to clean and maintain, making them an ideal choice for food kiosks. Furthermore, these panels offer thermal insulation, helping to maintain the appropriate temperature for storing and serving food, regardless of the climate. In addition, sandwich panels are lightweight, facilitating effortless transportation and assembly. This allows for quick setup and relocation if necessary. Moreover, they possess remarkable structural strength, ensuring stability and security for the kiosk. All in all, due to their durability, insulation properties, hygienic surfaces, and ease of installation, sandwich panels are a suitable option for food kiosks.

- Q:Color steel tile and Caigang sandwich board What is the difference between the use of what is the difference

- That depends on the savvy! Way more than difficult!

- Q:General color steel foam sandwich panels. How much a square is flat

- Big core board price is cheaper than the core board, the vertical (to the core material to distinguish) bending strength is poor, but the lateral bending strength than

- Q:I would like to open a 500 square meters processing sandwich panels. Color steel mills to invest much money

- Light steel plant roof static load can be divided into the following . the roof for the single-layer + cotton insulation, 0.20KN / M. the roof for the double board + insulation cotton, 0.25KN / M. the roof for the foam sandwich panels, if 50 thick, 0.3KN / M2 specific calculation, assuming purlin per meter specific gravity of . the distance is 1.. then converted to 7 / 1.5 = 5 kg or so insulation cotton generally in 1 kg, pull the sub-component 2 kg, single Floor panel 0.5 thick -0.5 * 7.85 = 4 kg then the roof of a single board + insulation cotton, constant load of 5 +1 +2 +4 = 12 kg per square meter of the actual design time to enlarge the point, take a 0.. Otherwise your trial is also very sad to give you a reference, hope useful

- Q:Will the use of color steel sandwich panels ceiling package package how much money a square? M14 round steel to do hanging bars, 950 sandwich panels, the main bone 160 * 60 * 20 * 2.5 C steel Is the workshop ceiling, I should quote how much appropriate,

- Excavation works of earth and rock.The construction unit should prepare a special program

- Q:Steel structure workshop roof load is the number of specific Please thank you

- Contents The first chapter of the construction site safety technical information management of the main contents and requirements Section I construction site safety technical information management of the meaning of Section II of the construction site safety technology management system Section III construction site safety technical information Four sections of the construction site safety technical information classification The second chapter of the construction site safety management information Section I in progress construction safety supervision and related documents (the first file box) Section II safety production responsibility system (the second file box) third (The third file box) Section IV of the safety of the construction organization design (the fourth file box) Section V Division (sub-project) Safety Technology to the end of the (fifth file box) Section VI security check (sixth file Box) Section VII of the safety education (the seventh file box) Section VIII of the pre-class security activities (eighth file box) Section IX special operations certificates (ninth file box) Section X accident (the tenth file box ) Section XI Safety signs (eleventh file box) Section XII security equipment and machinery and equipment related to the management of documents (the twelfth file box) thirteenth Machinery and equipment, facilities acceptance test records (thirteenth file box) Section XIV construction of temporary electricity (the fourteenth file box) Section fifteenth civilized construction (fifteenth file box) trade union labor protection information

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Environment-protection Heat Insulation EPS Cement Sandwich Panel for Prefab House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords