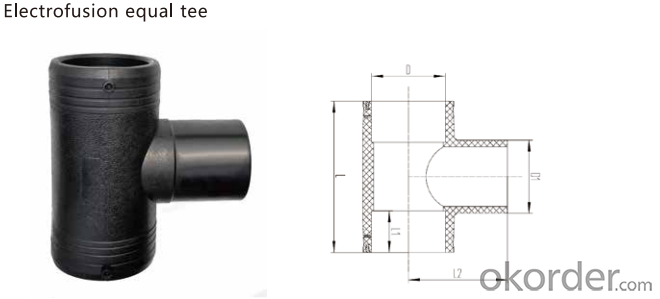

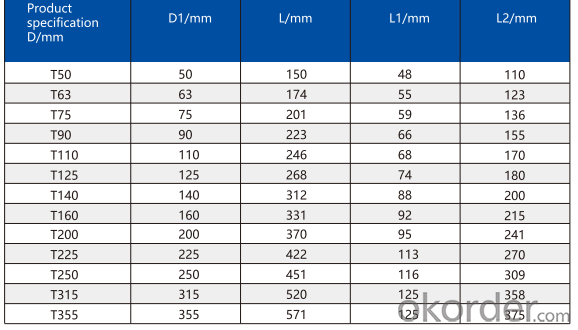

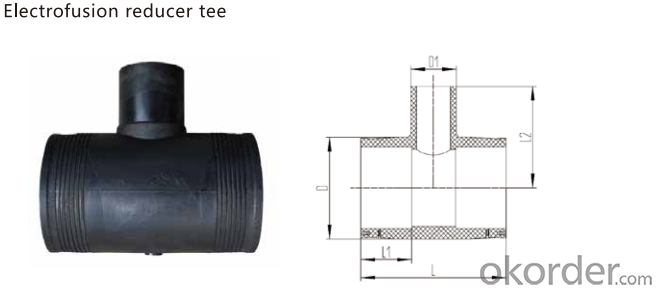

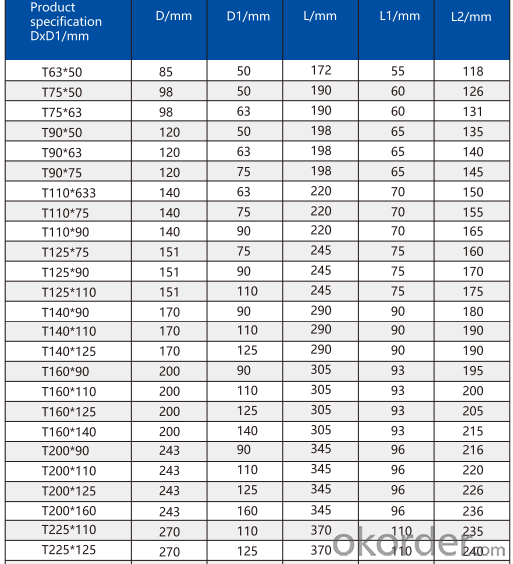

Electrofusion Equal Tee Reducer TEE PE Pipe Fittings EN12201-3

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Electrofusion Equal Tee Reducer TEE PE Pipe Fittings EN12201-3

Pressure grade:≤1.6MPa

Size: DN50MM-DN355MM

Specification:

Pressure grade:≤1.6MPa

Size: DN50MM-DN1000MM

Specification:

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q:Are plastic pipe fittings available in different colors?

- Yes, plastic pipe fittings are available in different colors.

- Q:How do you connect plastic pipe fittings to cast iron pipes?

- To connect plastic pipe fittings to cast iron pipes, you can use a rubber coupling with stainless steel clamps. This coupling is designed to create a tight seal between the two different materials, ensuring a secure connection.

- Q:Can plastic pipe fittings be used in pharmaceutical systems?

- No, plastic pipe fittings are not recommended for use in pharmaceutical systems due to concerns about potential leaching of chemicals or contaminants into the pharmaceutical products. Stainless steel or other suitable materials are typically preferred for such applications to ensure the highest level of safety and quality.

- Q:How do you remove a plastic pipe fitting?

- To remove a plastic pipe fitting, you typically need to follow these steps: 1. Turn off the water supply: Locate the main water valve and shut it off to prevent any leaks or water flow while removing the fitting. 2. Drain the pipe: Open a faucet or valve downstream from the fitting to drain any water remaining in the pipe. 3. Cut the pipe: Using a pipe cutter or hacksaw, carefully cut the plastic pipe on both sides of the fitting. Be cautious not to damage the adjacent pipe or the fitting itself. 4. Loosen the fittings: Depending on the type of fitting, you may need to use a wrench or pliers to loosen and remove any nuts, clamps, or rings securing the fitting to the pipe. 5. Separate the fitting: Once the nuts/clamps are loose, gently twist and pull the fitting away from the pipe. If it's stubborn, applying heat with a heat gun can help soften the plastic and make it easier to remove. 6. Clean the pipe ends: After removing the fitting, use a utility knife or sandpaper to clean any burrs or debris from the pipe ends before installing a new fitting or reconnecting the existing one.

- Q:Are plastic pipe fittings suitable for mining operations?

- Yes, plastic pipe fittings can be suitable for mining operations. Plastic pipe fittings offer several advantages such as corrosion resistance, lightweight construction, and ease of installation. Additionally, plastic pipe fittings can withstand high pressures and are durable, making them suitable for various mining applications. However, the specific requirements and conditions of each mining operation should be considered to ensure proper selection and installation of plastic pipe fittings.

- Q:How do plastic pipe fittings compare to copper fittings?

- Plastic pipe fittings and copper fittings have their own distinct advantages and disadvantages. While copper fittings have been widely used for many years and are known for their durability and reliability, plastic fittings have gained popularity due to their cost-effectiveness and ease of installation. Copper fittings are known for their resistance to corrosion and high pressure, making them suitable for demanding applications such as plumbing systems. On the other hand, plastic fittings are lightweight, non-corrosive, and resistant to chemicals, making them ideal for applications that require flexibility and easy handling. Ultimately, the choice between plastic and copper fittings depends on the specific requirements of the project, budget constraints, and personal preferences.

- Q:Can plastic pipe fittings be used in vacuum systems?

- Yes, plastic pipe fittings can be used in vacuum systems. However, it is important to consider the specific requirements and limitations of the vacuum system, such as the level of vacuum, temperature, and chemical compatibility. Some plastic materials may not be suitable for high vacuum applications or may have limited temperature or chemical resistance. It is recommended to consult with experts or manufacturers to ensure the selected plastic pipe fittings are appropriate for the specific vacuum system.

- Q:What are the common maintenance requirements for plastic pipe fittings?

- Common maintenance requirements for plastic pipe fittings include regular inspection for cracks or leaks, cleaning to remove debris or sediment buildup, and proper tightening of connections to ensure a secure fit. Additionally, it is important to avoid using harsh chemicals or excessive force during installation or maintenance, as this can damage the fittings.

- Q:How to calculate joint parts for hot melt connection of water supply plastic pipe?

- If flanges, flanges, or hot melt inserts or electrofusion connections are used, the fittings shall be determined according to the design drawings and field conditions.

- Q:Are plastic pipe fittings suitable for hydronic heating systems?

- Yes, plastic pipe fittings are suitable for hydronic heating systems. They offer various benefits such as corrosion resistance, ease of installation, and cost-effectiveness. Plastic fittings also provide excellent performance in terms of durability and reliability, making them a popular choice for hydronic heating applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electrofusion Equal Tee Reducer TEE PE Pipe Fittings EN12201-3

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords