E-glass Fiberglass Woven Roving 400gsm-1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

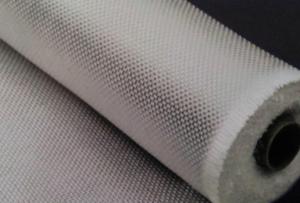

Structure of woven roving Description

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

Main Features of the woven roving

1)Drapes well to suit the surface of intricate moulds

2)Fast wet-through and wet out

3)Easy handing and better appearance of the composite parts

4)Compatible with Unsaturated polyester resin

5)Very high laminate strength properties

Woven roving Images

Woven roving Specification:

Normal type | EWR800 | EWR400 | EWR300 | EWR500 | EWR600 |

Thickness (mm) | 0.8 | 0.4 | 0.3 | 0.5 | 0.6 |

Density(warpxweft) (end/cm) | 1.8x1.5+/-10% | 3.6x3.2+/-10% | 4.6x4.1+/-10% | 2.2X2.0+/-10% | 2.6X2.4+/-10% |

Tex (warpxweft) | 2400x2400 | 600X600 | 300x400 | 1200x1200 | 1200X1200 |

Moisture content(%) | <0.2% | <0.2% | <0.2% | <0.2% | <0.2% |

Loss on ignition(%) | 0.4 – 0.8 | 0.4-0.8 | 0.4-0.8 | 0.4-08 | 0.4-0.8 |

Width(cm) | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 |

Weight (g/m2) | 816+/-41 | 408+/-32 | 300+/-15 | 500+/-25 | 600+/-30 |

Weight per roll(kg) | 45 | 46 | 50 | 45 | 45 |

Glass | E-glass | E-glass | E-glass | E-glass | E-glass |

FAQ of woven roving:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

Application of Fiberglass Woven Roving:

a) boats ,vessels ,plane

b) automotive parts ,furniture and sports facilities

c) resins system,such as polyeser,vinylester and epoxy resins

- Q:How does fiberglass mat tissue perform in terms of chemical resistance?

- Fiberglass mat tissue is renowned for its exceptional chemical resistance capabilities. This material is typically composed of glass fibers held together by a binder, enabling it to withstand a wide range of chemicals. This makes it a popular choice as a reinforcement in composite materials, like fiberglass-reinforced plastics (FRP), as it can endure exposure to various chemicals without degradation. The level of chemical resistance in fiberglass mat tissue can vary depending on its specific type, quality, and the chemicals it encounters. However, it generally exhibits high resistance to acids, alkalis, solvents, and other corrosive substances. This quality makes it suitable for applications where the material may come into contact with aggressive chemicals, such as in chemical processing plants, water treatment facilities, or storage tanks. It is important to acknowledge that while fiberglass mat tissue is generally chemically resistant, it may not be completely impervious to all chemicals. Certain highly concentrated or specialized chemicals may still have the potential to cause damage or deterioration over time. Therefore, it is always advisable to consult the manufacturer's specifications and recommendations for detailed information on chemical resistance before utilizing fiberglass mat tissue in a particular application. All in all, fiberglass mat tissue's robust chemical resistance properties establish it as a dependable option for applications involving chemical exposure.

- Q:What are the typical roll sizes available for fiberglass mat tissue?

- The typical roll sizes available for fiberglass mat tissue vary depending on the manufacturer and the specific application. However, in general, fiberglass mat tissue is available in roll sizes ranging from 50 inches to 120 inches in width and 100 yards to 1,000 yards in length. These sizes are commonly used in industries such as construction, automotive, and marine for various purposes like insulation, reinforcement, and soundproofing. It is important to note that the availability of specific roll sizes may differ based on the supplier and the intended use of the fiberglass mat tissue.

- Q:How is fiberglass mat tissue used in the production of storage sheds?

- The production of storage sheds commonly utilizes fiberglass mat tissue due to its exceptional strength and durability. This material is typically employed as a reinforcement to enhance the structural integrity of the shed's walls, roof, and floor. During manufacturing, fiberglass mat tissue is frequently applied to both the exterior and interior surfaces of the shed. It is initially impregnated with a binding resin, usually polyester or epoxy. The resin-soaked fiberglass mat tissue is then layered onto the shed's panels or molds. Once in position, the resin is cured, either through heat application or a chemical reaction, which solidifies the material. This process creates a rigid, lightweight composite structure that is highly resistant to cracking, warping, and rotting, as well as being weather-resistant. The fiberglass mat tissue acts as a reinforcing layer, providing additional strength and stability to the shed. It helps evenly distribute loads across the structure, making it more resistant to impacts and external forces. Additionally, it prevents the shedding of particles, enhancing the overall appearance and cleanliness of the shed. Moreover, fiberglass mat tissue offers excellent thermal insulation. This insulation helps regulate the shed's temperature, keeping it cool in the summer and warm in the colder months. It also reduces energy costs by minimizing heat transfer. In conclusion, the inclusion of fiberglass mat tissue significantly improves the durability, strength, and insulation capabilities of storage sheds. It ensures a long-lasting and reliable structure that can withstand various weather conditions while providing a comfortable and secure storage space.

- Q:How is fiberglass mat tissue used in the production of chemical reactors?

- Fiberglass mat tissue is used in the production of chemical reactors as a reinforcement material. It is typically applied to the inner surface of the reactor to provide structural strength, enhance resistance to corrosion, and improve overall durability. The fiberglass mat tissue acts as a barrier against chemical reactions, preventing leaks or damage to the reactor. Additionally, it helps maintain a stable temperature inside the reactor, ensuring efficient and safe chemical processes.

- Q:How does fiberglass mat tissue compare to mineral wool insulation?

- Fiberglass mat tissue and mineral wool insulation have different properties and applications. Fiberglass mat tissue is typically used as a reinforcement material for composites or as a facing material for insulation products. It provides good strength, flexibility, and resistance to moisture. On the other hand, mineral wool insulation is primarily used for thermal and acoustic insulation in buildings. It offers excellent fire resistance, sound absorption, and thermal performance. While both materials have their own advantages, the choice between them depends on the specific requirements of the project.

- Q:What are the different reinforcement densities available for fiberglass mat tissue?

- The reinforcement densities available for fiberglass mat tissue can vary depending on the specific application and manufacturer. Different densities, ranging from 15 gsm to 1000 gsm, are commonly used. For lightweight applications where strength and durability are not the primary concerns, lower density fiberglass mat tissue in the 15-50 gsm range is often utilized. These mats are commonly found in decorative surfaces, wallpaper, and lightweight insulation. Medium density fiberglass mat tissue, ranging from 50-300 gsm, offers a balance between strength and weight. This range is frequently used in industries such as construction, automotive, and marine. The medium density mats provide good reinforcement properties while remaining flexible and easy to handle. In heavy-duty applications that require high strength and superior durability, higher density fiberglass mat tissue, typically above 300 gsm, is employed. These mats are commonly used in roofing, flooring, and composite manufacturing. The higher density provides improved mechanical properties and ensures structural integrity. Ultimately, the choice of reinforcement density for fiberglass mat tissue depends on the specific requirements of the application, including desired strength, weight, and overall performance characteristics. It is advisable to consult with manufacturers and industry experts to determine the most suitable density for a particular use case.

- Q:What is the weathering resistance of fiberglass mat tissue?

- The weathering resistance of fiberglass mat tissue is generally considered to be high. Fiberglass mat tissue is made from a combination of fiberglass strands and a binder material, such as polyester or acrylic. This combination creates a strong and durable material that is resistant to various weathering factors, including exposure to sunlight, moisture, and temperature fluctuations. The fiberglass strands in the mat tissue provide excellent mechanical strength, preventing the material from breaking down under external stress or pressure. This strength helps the mat tissue withstand the impact of wind, rain, and other weather elements without significant damage. Additionally, the binder material used in the manufacturing process of fiberglass mat tissue is often formulated to be resistant to UV radiation. This UV resistance helps to protect the material from degradation and color fading caused by prolonged exposure to sunlight. It also helps to maintain the structural integrity and strength of the mat tissue over time. Furthermore, fiberglass mat tissue is also resistant to moisture and water absorption. This resistance prevents the material from becoming weakened or deteriorated when exposed to rain, humidity, or other moisture sources. As a result, the mat tissue remains intact and retains its performance properties even in wet or humid conditions. Overall, the weathering resistance of fiberglass mat tissue is considered to be excellent, making it a popular choice for various applications where durability and longevity in outdoor environments are required.

- Q:Can fiberglass mat tissue be used for reinforcing swimming pools?

- Swimming pools can be reinforced with fiberglass mat tissue, a robust and enduring material widely employed in diverse construction projects. This lightweight and flexible material is highly resistant to water, chemicals, and corrosion, making it an excellent option for reinforcing swimming pool structures. To apply the fiberglass mat tissue, it is typically affixed to the pool surface using a resin-based adhesive, resulting in a powerful bond that enhances the pool's strength and stability. Furthermore, the use of fiberglass mat tissue can effectively deter cracking and increase the lifespan of the swimming pool, rendering it a favored choice among pool builders and owners.

- Q:How does fiberglass mat tissue perform in terms of thermal expansion?

- Fiberglass mat tissue has a relatively low thermal expansion coefficient, meaning it expands minimally when exposed to heat. This characteristic makes it an excellent material for applications where thermal stability is crucial. The tightly woven structure of fiberglass mat tissue helps to limit the expansion and contraction of the material, even under high temperatures. Consequently, it exhibits excellent dimensional stability and resistance to thermal stresses. This property allows fiberglass mat tissue to maintain its structural integrity when exposed to extreme temperature variations, making it highly suitable for use in industries such as aerospace, automotive, and construction, where thermal expansion and contraction can pose significant challenges.

- Q:Is fiberglass mat tissue resistant to moisture vapor transmission?

- Yes, fiberglass mat tissue is resistant to moisture vapor transmission.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

E-glass Fiberglass Woven Roving 400gsm-1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords