Drywall Metal Stud for Australia And New Zealand

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

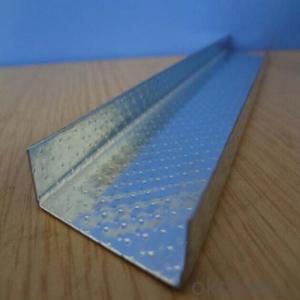

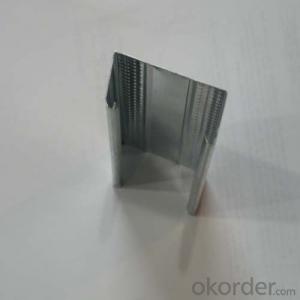

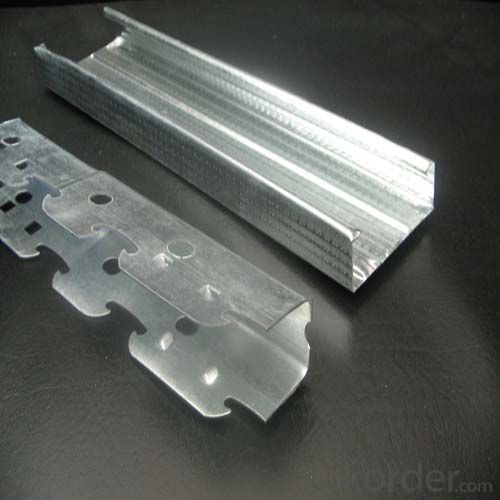

Australia drywall metal stud, drywall stud and track connection size:51/64/76/92/150mm ,thickness:0.55-1.15mm,galvanized z275g.

Australia metal drywall stud,1)Standard in Australia , 2)Thickness:0.5-1.5mm, 3)zinc coating:120-275g ,4)Very Perpendicular, 5)Support is fast construction, 6)Length size according to the customer size manufacture

Specification

PART NO | DESCRIPTION | Size(mm) | Length(mm) |

125 | 25mm Top Cross Rail | 25*21*0.55 | 3600/4800/6000 |

127 | 25mm Top Cross Rail | 25*21*0.75 | 3600/4800/6000 |

308 | 16mm Furring Channel Track | 16*20*30*0.55 | 3000 |

129 | 28mm Furring Channel Track | 28*20*30*0.55 | 3000 |

301 | 16mm Ceiling Batten | 36*16*0.5 | 4800/6000 |

303 | 22mm Cyclonic Ceiling Batten | 35*22*68*0.55 | 4800/6000 |

310 | 40mm Ceiling Batten | 35*40*70*0.55 | 4800/6000 |

308 | 16mm Furring Channel | 16*38*0.55 | 3000/3600/4800/6000 |

129 | 28mm Furring Channel | 28*38*0.55 | 3000/3600/4800/6000 |

401/489 | 51mm Stud | 51*33.5*35.5*0.55/0.75 | 2400/2700/3000/3600/4200/4800/6000 |

112/491/661 | 64mm Stud | 64*33.5*35.5*0.55/0.75/1.15 | 2400/2700/3000/3600/4200/4800/6000 |

403/493/671 | 76mm Stud | 76*33.5*35.5*0.55/0.75/1.15 | 2400/2700/3000/3600/4200/4800/6000 |

251/495/681 | 92mm Stud | 92*33.5*35.5*0.55/0.75/1.15 | 2400/2700/3000/3600/4200/4800/6000 |

511/691 | 150mm Stud | 150*33.5*35.5*0.75/1.15 | 3600/4800/6000/7200 |

400/490 | 51mm Track | 51 * 32/50 * 0.55/0.75 | 3000 |

111/492/660 | 64mm Track | 64 * 32/50 * 0.55/0.75/1.15 | 3000 |

402/494/670 | 76mm Track | 76 * 32/50 * 0.55/0.75/1.15 | 3000 |

250/496/680 | 92mm Track | 92 * 32/50 * 0.55/0.75/1.15 | 3000 |

510/690 | 150mm Track | 150 * 32/50 * 0.75/1.15 | 3000 |

Leg Stopping Angle 6mm | 30*6*0.4 | 3000 | |

P25 | Leg Stopping Angle 10mm | 30*10*0.4 | 3000 |

P26 | Leg Stopping Angle 13mm | 30*13*0.4 | 3000 |

P27 | Leg Stopping Angle 16mm | 30*16*0.4 | 3000 |

P01 | External Angle 90 | 30*30*0.4 | 2400/2700/3000/3600 |

P50 | Shadowline stopping angle | 10*10*30*0.4 | 3000 |

PART NO | DESCRIPTION | Thicknes |

Adjustable Direct Fix | 1.5mm | |

Beta Fix | Beta Fix | 1.5mm |

Long Beta Fix | Long Beta Fix | 1.5mm |

167 | Side mounted TCR Suspension Clip | 0.8mm |

139 | Locking Key | 0.7mm |

2534 | TCR Suspension Clip | 0.8mm |

121 | 5mm Rod Suspension | 5mm |

305 | Direct Fix Clip -150 long | 1.0mm |

314 | Direct Fix Clip-92 | 1.0mm |

247 | Right Angle Rod Bracket | 1.2mm |

274 | R0d Brackets | 1.2mm |

Ceiling Bracket | 1.6mm | |

Floor Pin | ||

239 | Direct Fixing Clips—Screw Fix | 1.2mm |

237 | Direct Fixing Clips-Concrete | 1.2mm |

394 | Direct Fixing Clips 175mm | 1.0mm |

226 | Direct Fixing Clips 75mm | 1.0mm |

SWC3 | Slotted Web Cleat | 3mm |

Product Overviews

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q:75 light steel keel wall to do 6m high, need reinforcement? How to strengthen?

- Must do 75 keel, it is recommended to add angle iron or square tube reinforcement, do not forget to do heart keel

- Q:Light steel keel to do a layer of gypsum board layer of nine layers of the wall how much money a square, the price is simple or double-sided?

- The price is simple, carpentry is a board how much money, such as a ceiling, like a plate 90 so. Two boards have to double-sided settlement, how have one hundred fifty six one flat it

- Q:Lightweight wallboard light steel keel how to construction

- Damp room and steel plate plaster wall, light partition board keel spacing should not be greater than hundreds of millimeters, the installation of supporting keel, the support card should be installed in the direction of the vertical keel opening, partition wall card should be four hundred To six hundred millimeters, from the keel at both ends of the distance should be twenty to twenty five millimeters, should be fixed according to the location of the ball along the edge, along the keel and border keel, keel line should be coincident with the line.

- Q:Light steel keel gypsum board partition wall construction practices and construction process What is the difference?

- The practice is to first play on the ground and shed on the corner keel must be vertical after the installation of the main keel times the keel installed in the plaster board plaster brush latex paint difference is stronger than the keel cost is higher than the wood keel

- Q:Light steel keel gypsum board partition should pay attention to what quality problems

- 1, contact with the stability of the keel through the keel when the wall height of not more than 3m can be set to a wall height of 3-5m should be set up two, more than 5m should be set to 3. 2, light steel keel gypsum board partition wall should be done to the structure board. 3, for the sound insulation requirements of the partition, should be along the top keel and along the keel and the main structure of the junction, the pad with long sound insulation tape, and in the gypsum board and the main structure of the embedded sealant, Fill 50mm thick glass wool.

- Q:In a layer of 6 meters high in the big room, do 2.8 meters high light steel keel partition. Big room to do mineral wool board ceiling, how to connect the two?

- Can be directly connected, but not solid. How are they all know what they are.

- Q:Will the light steel keel, brick block, light partition wall do inside the wall what are the advantages. Including the price, as much as possible, thank you!

- Light steel keel life in humid environment Short brick block from the weight of large but because the single volume of small transport more convenient light partition board can be used for humid environment but a single volume upstairs is not convenient to install as light steel keel convenience The cost gap is not big

- Q:To warm the above has been tiled, with light steel keel to build a wall, how to fix the keel?

- With a hammer to drill the ground hole can be fixed to the ground. With glue, it is certainly impossible to nail

- Q:Light steel keel partition wall how to get, and how to purchase materials and tools, I now empty-handed, the best comprehensive ~!

- Light steel keel can be purchased in the decorative materials market, as long as there is a place to sell gypsum board there are light steel keel sold, you can ask. Fixed light steel keel before the need for the wall or the ground, the top with the impact drill drilling, and then smashed the wooden wedge, and then nail or self-tapping screws to light steel keel fixed up. The use of tools for the production of light steel keel partitions, generally have impact drill, cutting machine, hand drill, etc .; gypsum board is a self-tapping screw fixed to the light steel keel frame, which requires hand drill plus cross-head operation; Light steel keel wall vertical keel, according to the center position of 40 cm spacing arrangement, the specific number of how much is based on the total length of the wall to calculate; gypsum board side must be fixed on the light steel keel, Self-tapping screws on the surface of the gypsum board to do just the right, not too deep, can not be too shallow. The screw is too deep, it can not get the role of fixed gypsum board, and too shallow, and will reveal the surface of the gypsum board, which will affect the batch of scraping scraping.

- Q:House decoration, the designer said the wall with light steel keel good, but the construction told me that this low efficiency can only be maintained for 4,5 years so I do not know in the end listen to who

- Load on the best no problem with red brick, that wall how many square meters, if the area is less than 10 square meters can be brick 120 red brick wall

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Drywall Metal Stud for Australia And New Zealand

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords