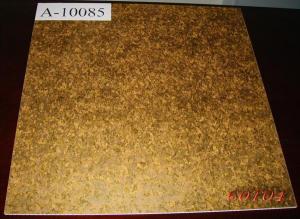

Ceiling board calcium silicate plate Grade 5A

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

- Option:

- 595*595 603*1213 595*1195 603*603

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Ceiling board

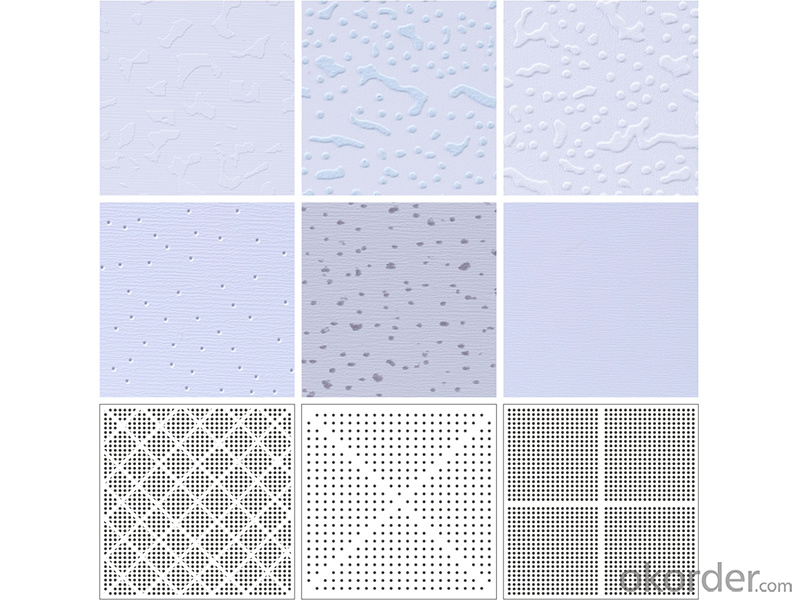

It is a ceiling plate series based on the development of calcium silicate plate. With the comprehensive performance of calcium silicate plate, the surface of the plate is different in embossing, relief, sandblasting, perforation, semi-perforation, printing, tegular level and so on

Detailed introduction

Product features: Lightweight, sound absorption, subsidence resistance, fire prevention, moisture-proof, no dust fall, strong decoration.

Product application

Grade 5A or Grade A office buildings, five-star hotels, entertainment venues, shopping malls, factories, offices, hospitals, theaters, stations, stations, schools, airports, railway stations, etc

- Q:Calcium silicate board sticky rock wool sandwich sandwich board what glue stick to live?

- One-component modified silane glue can try HMS60, if polyurethane glue can also be

- Q:Calcium silicate board production mode, the copy method and the quality of the comparison method, which prawn know

- At present, with the improvement of process control level, the gap is not so big, the capacity of the upstream slurry method by increasing the width of the blanket, the quality of the press and template surface treatment to enhance, but the relative equipment investment will be large ( Japan and Taiwan can not copy the template, but because of the differences in the level of process control, the majority of domestic product copy quality products can not reach the level of the Japanese level). There are two ways to integrate business, such as Etienne, with a blanket, the production of different products can be two ways to switch at any time.

- Q:The real production of non-asbestos calcium silicate board manufacturers which is the company, and now all the calcium silicate board manufacturers are blowing their own asbestos-free, hoping to have a real asbestos

- That I really do not know, now the calcium silicate board without asbestos manufacturers: Eturne, Matsumoto, overseas Chinese building materials are pure cotton-free, but Etienne and Matsumoto price is too high, if the choice Or the price of overseas Chinese jade building materials is still very reasonable! Hope to help you!

- Q:What are the advantages of calcium silicate board?

- The strength of more than 10MPA than most of the plate strength are high; density between 0.6-1.4 (in addition to some of the higher strength of the pressure forming plate), as insulation materials more energy; the use of wood fiber and inorganic high temperature, In the high humidity state does not decompose the decomposition of non-toxic gases (decomposition only release water vapor); due to calcium carbonate plate autoclaved products and air in the water vapor, oxygen, carbon dioxide do not react, so the service life is equivalent to building life The

- Q:Glass magnesium board VS calcium silicate board who can be better

- Glass magnesium board is made of magnesium oxide, magnesium chloride, water ternary system is modified by the configuration, because of its A-class fire, water and moisture, while green, in line with the characteristics of sustainable development, by the state recommended.

- Q:Calcium silicate board commonly known as what

- Insulation with calcium silicate board is called microporous calcium silicate, is a white, hard new insulation material, with a light weight, high strength, thermal conductivity is small, high temperature, corrosion resistance, can cut, Widely used in electric power, metallurgy, petrochemical, construction, ship and other areas of equipment piping, wall roof insulation and fire insulation. Thickness is usually above 30mm. Density in the 200-1000kg / m3.

- Q:Calcium silicate board wall can be directly putty putty

- Because the calcium silicate board (plate) surface is relatively smooth, directly in the calcium silicate board (plate) on the batch of putty powder prone to fall off (gray) phenomenon, first primer.

- Q:Calcium sulfate anti-static flooring and calcium silicate board What are the differences

- This floor is generally with HPL melamine veneer, good wear resistance. And because the rough surface of the substrate is easy to glue, bonding is very strong, never crack. In addition, can also be made of core-board, plate-based six sides are galvanized sheet, so that can be used as a network floor, for carrying high demand for office space. This is a "wide applicability" of the product, can be used for all aerial flooring occasions, especially carrying high requirements of the engine room, office space, and it is not demanding maintenance, long service life.

- Q:Jinfu calcium silicate board and Matsumoto easy hair board that kind of good?

- For the two kinds of roughly the same new building materials, the production process with the copy method and flow slurry method. The thickness of the plate is 6mm ~ 12mm, the apparent density of about 600kg / m3 ~ 1200kg / m3 large-size sheet, can be used as buildings inside and outside the wall panels, ceilings, etc., suitable for the production of slurry thickness of 19mm ~ 32mm, the apparent density of about 750kg / m3 ~ 900kg / m3 of the plate. The use of copy or flow slurry method to produce calcium silicate board or fiber reinforced calcium silicate board has a heat, fire these two major performance.

- Q:I would like to do three partitions in the room, with fiber cement board, gypsum board, fiber calcium silicate board which is better?

- I think two kinds of almost the key is the role of fiber from the absorption of sound. If you can not knock the sound, you try thick on the line.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceiling board calcium silicate plate Grade 5A

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

- Option:

- 595*595 603*1213 595*1195 603*603

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords