Carbon Steel Hot Rolled Wire Rod with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Carbon Steel Wire Rod at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Carbon Steel Wire Rod are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.After hot-rolled the products shaped into coil and delivery as finished product, including round, square, rectangular, hexagonal and so on. Since most of the products are round, it is generally called wire rod. Carbon steel wire rod is widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

Product Advantages:

OKorder's Carbon Steel Wire Rod are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Chemical Composition:

Please kindly find our chemistry of our material based on SAE1008B as below for your information

Trademark | Rank | Chemical composition (quality score) % | |||||

C | Si | Mn | S | P | |||

≤ | ≤ | ≤ | |||||

Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 | |

Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 | |

Trademark | Rank | Pulling Test | |||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | |||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | ||||||

≤16 | 16-40 | ≤16 | 16-40 | ||||

≥ | ≥ | ||||||

Q235 | A | 235 | 225 | 375-500 | 26 | 25 | |

Q235 | B | 235 | 225 | 375-500 | 26 | 25 | |

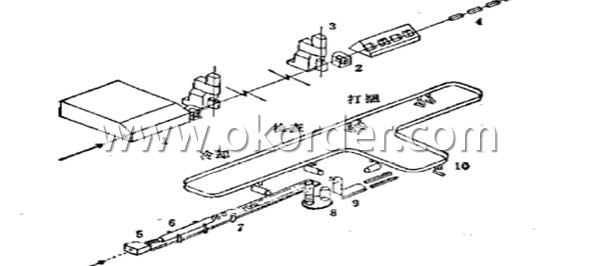

Production Process of Wire Rod

1-Furnace 2-Roughing Mill 3-High-speed Finishing Mill 4-Water-cooled Device 5-Coiling Device

6-Cooling Device 7-Chain Conveyer 8-Spool Collecting Device 9-Spool Down Device 10-Hook Conveyer

Packaging & Delivery of Wire Rod:

Packaging Detail: products are packed in coil and then shipped by container or bulk vessel

Each coil weight: 2-3MT

Delivery Detail: within 45 days after received deposit or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: CFR, CIF

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Image

- Q:What are the common packaging methods for steel wire rod?

- The common packaging methods for steel wire rod include coiling the rod into large coils, bundling the rod into smaller bundles, or spooling the rod onto a reel.

- Q:What are the standard bending requirements for steel wire rod?

- The standard bending requirements for steel wire rod typically depend on the specific industry or application in which the wire rod is being used. However, there are certain general guidelines and specifications that are commonly followed. One of the key factors in determining the bending requirements is the diameter or gauge of the steel wire rod. Thicker wire rods generally require a larger bending radius compared to thinner ones. This is to ensure that the wire rod does not undergo excessive strain or deformation during the bending process. Another important consideration is the type of steel used in the wire rod. Different types of steel have varying levels of ductility and tensile strength, which can impact the bending requirements. It is crucial to adhere to the manufacturer's specifications and guidelines to ensure the wire rod is not subjected to excessive stress or damage during bending. In addition to these factors, industry standards and regulations may also dictate specific bending requirements for steel wire rods. For example, the American Society for Testing and Materials (ASTM) has established standards such as ASTM A510 which provides guidelines for the carbon steel wire rod used in various applications. Ultimately, the standard bending requirements for steel wire rod will depend on factors such as the diameter, type of steel, and industry standards. It is essential to consult relevant specifications and guidelines to ensure proper bending procedures are followed, thus maintaining the integrity and functionality of the wire rod.

- Q:Can steel wire rod be used in the production of wire mesh?

- Yes, steel wire rod can be used in the production of wire mesh. Steel wire rod is a raw material that is commonly used to manufacture various types of wire products, including wire mesh. Wire mesh is made by weaving or welding steel wires together to create a grid-like pattern. The steel wire rod is often drawn through a series of dies to reduce its diameter and increase its strength before being used to create the wire mesh. The resulting wire mesh is commonly used in a variety of applications such as fencing, construction, agriculture, and industrial settings.

- Q:What are the different types of packaging options available for steel wire rod?

- There are several packaging options available for steel wire rod, including coils, bundles, spools, and pallets. Coils are the most common packaging option, where the wire rod is wound into a circular shape and held together with binding material. Bundles involve grouping several lengths of wire rod together and securing them with straps or wire. Spools are used for smaller quantities and involve winding the wire rod onto a cylindrical core. Pallets are used for larger quantities and involve placing the wire rod on a wooden or plastic platform, often secured with straps or stretch wrap.

- Q:How is steel wire rod used in the manufacturing of wire rope slings?

- Steel wire rod is the primary raw material used in the manufacturing of wire rope slings. The rod is first drawn into wire and then twisted together to form strands, which are further twisted or braided to create the wire rope. The strength and durability of steel wire rod make it ideal for withstanding heavy loads and providing reliable lifting and rigging solutions in various industries.

- Q:What are the different cutting methods for steel wire rod?

- There are several different cutting methods for steel wire rod, including shearing, sawing, grinding, and laser cutting. Shearing involves using a cutting tool to separate the wire rod at a specific point, while sawing utilizes a saw blade to cut through the rod. Grinding involves using an abrasive wheel to remove material and cut through the wire rod. Laser cutting uses a high-powered laser beam to melt and vaporize the wire rod, creating a precise cut. Each method has its own advantages and is chosen based on the specific requirements of the application.

- Q:How is steel wire rod used in the production of conveyor belts?

- Steel wire rod is used in the production of conveyor belts as the main reinforcement component. It is typically formed into a spiral or helix shape and embedded in the rubber or plastic material of the belt. This reinforcement provides strength and durability to the conveyor belt, allowing it to withstand heavy loads and continuous movement. Additionally, the steel wire rod enhances the flexibility and stability of the belt, ensuring smooth and efficient transportation of materials.

- Q:What are the standard lengths available for steel wire rod?

- The standard lengths available for steel wire rod typically range from 2,000 to 2,500 meters.

- Q:How is steel wire rod used in the manufacturing of wire containers?

- Steel wire rod is a crucial component in the manufacturing of wire containers. Wire containers are widely used in various industries such as logistics, warehousing, and transportation for their durability, strength, and versatility. Steel wire rod is first transformed into wire through a series of processes, including drawing, annealing, and coating. The wire is then shaped and welded into the desired container design, whether it is a basket, cage, or pallet. The high tensile strength of steel wire rod ensures that the wire containers can withstand heavy loads and resist deformation, making them suitable for storing and transporting various goods. Moreover, the durability of steel wire rod enables the wire containers to withstand harsh environments, including extreme temperatures and corrosive substances. The flexibility of steel wire rod also allows for the customization of wire containers. Manufacturers can easily adjust the diameter, length, and thickness of the wire to meet specific requirements. This flexibility enables the production of wire containers in different sizes and designs, ensuring they can accommodate a wide range of products and fit into various storage systems. In addition to their strength and durability, wire containers made from steel wire rod are also lightweight, making them easier to handle and transport. This feature is especially beneficial in industries where frequent loading and unloading of goods are required. Overall, steel wire rod plays a vital role in the manufacturing of wire containers by providing the necessary strength, durability, and flexibility. Its usage ensures the production of reliable and efficient storage and transportation solutions for various industries.

- Q:How is steel wire rod tested for wear resistance?

- Steel wire rod is tested for wear resistance using various methods. One common approach is the pin-on-disk test, where a small pin made of the wire rod material is rubbed against a rotating disk under controlled conditions. The weight loss or wear rate of the pin is measured to determine its resistance to wear. Other tests may include abrasion testing, where the wire rod is subjected to continuous rubbing against an abrasive surface, or impact testing, where the wire rod is struck repeatedly to evaluate its durability. These tests help assess the wear resistance of steel wire rods and ensure their suitability for specific applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Steel Hot Rolled Wire Rod with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords