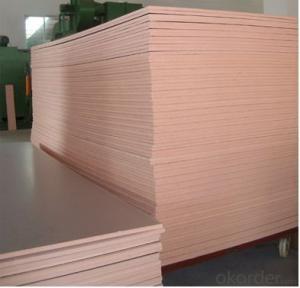

BP XPS Board for Cold Storage with CE and SGS Certification

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 64 m³

- Supply Capability:

- 30000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

BP XPS insulation board for cold stroage with CE and SGS certification

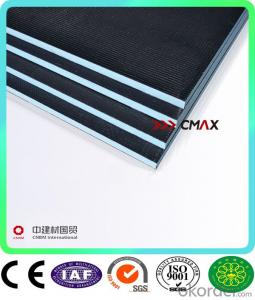

BP XPS is a extruded polystyrene thermal insulation foam board with proven high performance characteristics. its strengths speaks for itself, having a uniform closed cell rigid structure with virtual zero voids/pathways for moisture to enter. Offering high compressive strength with lower thermal conductivity, dimensional stability and resistance to below ground decay.

Certifications and testing report

Advantages:

1. high compression resistance

2. moisture-proof

3. airtight

4. non-absorbent

5. corrosion resistance

6. low thermal conductivity

7. lightweight

8. Life time:60 years

9. environmentally friendly

Data Sheet:

| Technical Data Sheet | |||

| Extruded Sheet (XPS) | |||

| Model | ×200 ×250 ×350 | ×400 ×450 ×500 ×600 | ×650 ×700 ×800 |

| Thermal Conductivity w/mk | 0.026 0.027 0.030 0.032-0.035 | ||

| Dimensional Stability | 0.3-1.0 | ||

| Applicable Temperature | -50°C - +75°C | ||

| Compression Strength kpa | 200 250 350 400 450 500 600 650 700 800 | ||

| Water Absorption | 0.3-1.0 | ||

| Density kg/m3 | 30-33 33-36 36-40 43-53 | ||

| Combustion Performance | GB8624-2012 Grade A, Grade B1 and Grade B2; GB8624-2006 Grade C or Grade B; GB8624-1997 Grade B1, | ||

| Oxygen Index | IO26-33 | ||

| Length | 1200 1450 1800 2400 | ||

| Width | 600 1200 | ||

| Thickness | 5 10 20 25 30 40 50 60 70 80 90 100 120 | ||

| Edge Shape | SS Flat Top SL Lap Joint TG Tenon RC Rain Gutter | ||

| Surface | Embossing Slotting Planing Smooth Surface | ||

| Applications | Insulation and Energy-Saving for Building Walls; Heat Preservation and Insulation for Cold Storage; Heat Preservation and Insulation for Roof; Stops and Side Panel on High-Speed Rail and Roads; Duct Pipe for Central Air Conditioner; Hydraulic Projects | Heat preservation and insulation for cold storage ground, steel-work roof, concrete roof construction; Frost-heave control for high-speed road, railway and airfield runway. | High-speed rail, CRTS track; Heavy cold storage ground. |

Applications:

It's widely used in wall insulation, cold storage, parking platforms, airport, railway, concrete roof construction, highways, etc.

- Q:Why extruded board (XPS board) is the best insulation board material

- Rong Sheng this section is quite good, the appearance of fashion, quiet, energy saving, computer temperature control, insulation effect is good

- Q:The traditional ceramic insulation board, the existing thermal insulation coating in addition to the process and the construction period there are similarities and differences there are differences? Which energy-saving building is better?

- Single-row fastener type steel pipe scaffold for decoration works in the construction of small horizontal bar spacing should be the number of mm.........................................................

- Q:Steel structure rock wool sandwich wall panel what the amount of this set

- Indoor insulation is generally made of "polystyrene foam board", the general thickness is 2..3 cm thick, you can understand clearly, in the end is how thick the foam board (when playing screw holes, can be found is thick thick foam board) The First play expansion bolts, do insulation, can say the details of the point. There is that you can use .7 inside the expansion of the screw, to Fu Fu Huang Peng, You can also use welding, then a long screw, is also very simple.

- Q:Roofing the top of the extruded polystyrene insulation board generally how much weight ah?

- Caigang rock wool sandwich panel Scope Caigang rock wool sandwich panels for drying room, paint room, industrial equipment, construction, ship insulation, noise, etc., at the same time for electronic clean room, clean room, explosion-proof fire shop ceiling , Cut off and so on. Fire time is 70 minutes. Thickness 50-150mm rock wool insulation board is basalt and other natural ore as the main raw material, rock wool insulation board by high temperature melt fiber, adding the right amount of binder, curing processing and made. Rock wool insulation board products for industrial equipment, construction, insulation, noise and so on. Color rock wool sandwich panels Product Features 1. Rock wool is inorganic insulation materials, iron ore slag as the main raw material, by melting, with high-pressure steam jet cooling, with a light, thermal conductivity is small, good elasticity , Non-combustible, non-rotting, non-rotting, chemical stability, and excellent sound insulation.2 The rock wool sandwich panels are widely used in addition to the general structure of heat insulation and insulation To the use of a variety of fire insulation places. Caigang rock wool sandwich board specifications thickness Caigang rock wool sandwich board sub-system board and manual board two, Caigang sandwich panel is made of two layers of color coated steel Layer, through the automatic compound molding machine, in the steel plate coated with adhesive glue, while embedded in the board on both sides of the thin-walled steel, the pressure, blanking made of sheet metal. . the mechanism of rock wool color steel sandwich panel specifications: L × 1150 × . L × 1150 × . L × 1150 × . handmade rock wool color steel sandwich panel specifications: L × 985 × . Sandwich panel thickness is divided into: 50mm, 75mm, 100mm, 150mm. . rock wool density: ≥ 120kg / m. thermal conductivity: ≤ 0.046w / m.k. combustion performance: A-level (non-combustible)

- Q:What is the difference between extruded polystyrene board and XPS insulation board?

- The interior design of the ceiling, to determine the location of the tuyere, and then design the HVAC professional with the design, after the design, you will find some outlet can not be arranged, or the ceiling must increase the outlet, and then install the factory twisted class defended straight gambling astringent leopard Adjusting the ceiling to adjust the drawings. In other words, this is the process of two professional cooperation with each other, but mainly based on the decoration ceiling map.

- Q:Polystyrene foam hard insulation board will not be harmful to the human body, right?

- Building safety production management issues, please choose the answer (multiple choice)

- Q:How is the flame and combustible defined by the naked eye? I burn the B1 level and B2 level XPS board is different? Question added: detection time is longer, can quickly and intuitively identified? More

- Air-conditioned room can not have flammable gas, in order to avoid explosion and fire do not frequent switch air conditioner, because the compressor starts when the current is running a lot of times the current, easy to burn the compressor motor 3) Do not put things on the outdoor unit of the air conditioner to avoid air conditioning noise. It is a great persecution for the air conditioner. The temperature of the general air conditioner is adjusted to 26 ° C to 28 ° C. , To avoid excessive power consumption next to the air conditioner must not be twitching Fengqi gong bite astringent ax to have a high temperature heat source, so as not to heat the panel deformation

- Q:Roof insulation layer is extruded polystyrene foam plate how set the amount of set

- The honeycomb structure of the thick plate, there is no gap, this closed-cell structure Insulation materials can have different pressures (150-500Kpa) at the same time have the same low value of the thermal conductivity (only 0.028W / MK) and enduring excellent insulation and compression performance, compressive strength up to 220-500Kpa.

- Q:I set up in October 2008, the production of XPS board - that is, with the extinction of polystyrene foam plastic plate, is an energy-saving environmental protection materials. Consult experts: I can enjoy the relevant tax incentives?

- Think of the safety data directory to compare the trouble to compare JGJ59-2011 check the information bar

- Q:Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- It is a white solid with a fine closed-cell structure which is heated and preformed in a mold by heating before it is made of a volatile liquid blowing agent.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

BP XPS Board for Cold Storage with CE and SGS Certification

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 64 m³

- Supply Capability:

- 30000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords