Borosilicate 3.3 Heat-resistant Glass(Microwave oven glass panel,glass tray)

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000000 pc/month

- Option:

- 2mm-20mm

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Borosilicate Float Glass3.3(BG33)

Product Introduction

This revolutionary glass is made of borosilicate, a special material that combines strength and durability with an extraordinarily high heat resistance.

Whether it's functional or decorative, this magnificent material will make any project look great while helping protect against extreme temperatures up to 500°C (932°F). And because of its excellent thermal shock properties, it won't cloud over time from frequent temperature fluctuations either!

Borosilicate float glass 3.3 is a special glass material with low expansion rate, high emperature resistance, high strength, high hardness, high light transmittance and high chemical stability.

Because of its excellent performance, it is widely used in household appliances, environmental engineering, medical technology, safety protection and other fields, especially in the field of household appliances, borosilicate float glass 3.3 is widely used as the panel and inner tray of ovens and microwave ovens. In addition, because the hardness of borosilicate float glass 3.3 is 8-10 times that of ordinary glass, it is also used as bulletproof glass by many customers.

Application field

Borosilicate 3.3 serves as a material of true function and wide applications:

1). Household electrical appliance (panel for oven and fireplace, microwave tray etc.);

2). Environmental engineering and chemical engineering (lining layer of repellence, autoclave of chemical reaction and safety spectacles);

3). Lighting (spotlight and protective glass for jumbo power of floodlight);

4). Power regeneration by solar energy (solar cell base plate);

5). Fine instruments (optical filter);

6). Semi-conductor technology (LCD disc, display glass);

7). Medical technique and bio-engineering;

8). Safety protection (bullet proof glass)

Advantages

High borosilicate 3.3 glass is high-temperature resistant glass, heat-resistant glass and temperature difference resistant glass. The linear expansion coefficient is 3.3 ± 0.1 × 10-6 / K, is a glass with sodium oxide (Na2O), boron oxide (b2o2) and silicon dioxide (SiO2) as the basic components. The content of boron and silicon in the glass composition is relatively high, namely, boron: 12.5 ~ 13.5%, silicon: 78 ~ 80%.

The expansion coefficient will affect the stability of glass. The expansion coefficient of borosilicate 3.3 heat-resistant glass is 0.4 times that of ordinary glass. Therefore, at high temperature, borosilicate 3.3 heat-resistant glass still maintains excellent stability and will not crack or break.

The long-term working temperature of borosilicate 3.3 heat-resistant glass can reach 450 ℃, so it is often used as the microwave oven panel. At high temperature, borosilicate 3.3 heat-resistant glass can not only work normally, but also maintain high permeability, which is convenient for users to observe the internal food state.

|

|

|

|  |

|

|

|

|

Our 3.3 borosilicate glass is extremely versatile too – you can use it for almost any purpose imaginable; such as microscope slides and petri dishes; kitchenware items like oven-proof baking dishes; art projects like stained-glass windows.the possibilities are endless! Its lightweight yet strong construction allows for easy transport between workspaces so you can take your creations wherever they need to go. And thanks to its crystal clear transparency, light passes through beautifully with no distortion whatsoever - making sure whatever design you come up with looks perfect every time!

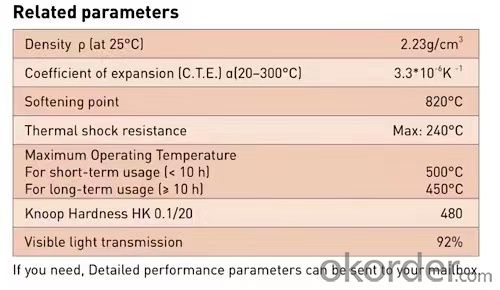

Technical Data:

Thickness Range: 2mm-20mm

Size: 1150*850 1700*1150 1830*2440 1950*2440 Max.3660*2440mm, other specifications can be produced according to customer requirements.

Color: ultra-clear, transmittance 92%

Thermal properties

Coefficient of Linear Thermal Expansion (C.T.E) α (20°C~300°C): 3.3×10-6 K-1

Specific heat capacity cƤ (20-100°C) :0.83kJ/(kg·K)

Thermal conductivity λ (90°C):1.2 W/(M·K)

Heat shock temperature:240°C

Annealing Point:560°C

Strain Point: 510°C

Optical data

Optical index of refraction:1.48

Mechanical properties

Density ρ (25°C) :2.23ɡ/cm3

Young's Modulus E (according to DIN 13316):64 kN/mm2

Poisson's Ratio μ (according to DIN 13316):0.2

Bending Strength σ (according to DIN 522922 T 1) :>25MPa

Packaging Photos of Borosilicate Glass 3.3

Package and transport

Minimum order quantity: 2 tons, capacity: 50 tons/day, packing method: wooden case.

Processing

Pre-cut formats, edge processing, tempering,drilling, coating, etc

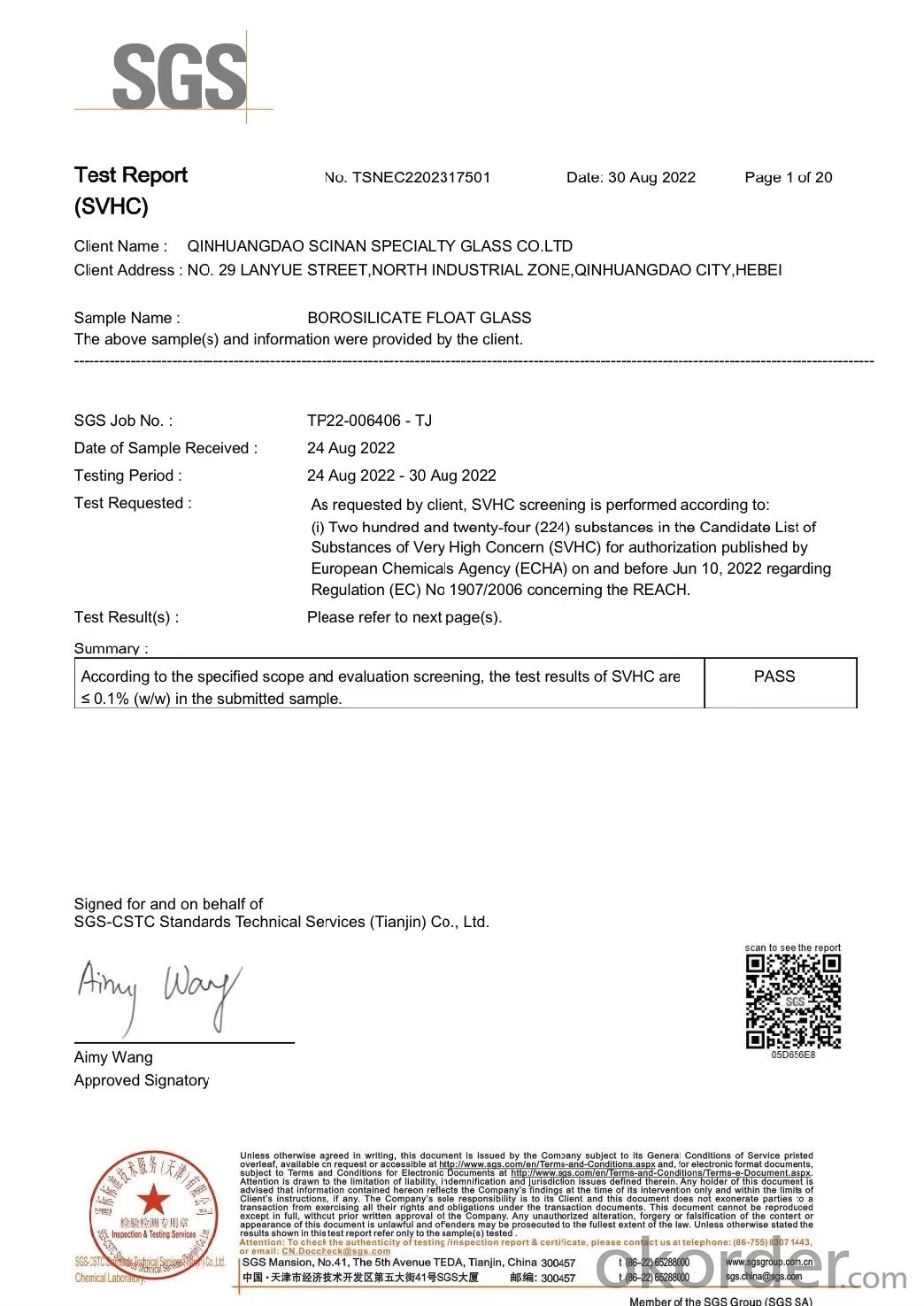

Our certification

At present, the company has passed the SGS certification the ISO9001 management system certification and so on. The company has 21 national patents and obtained the certification of high-tech enterprises.

Company Introduction

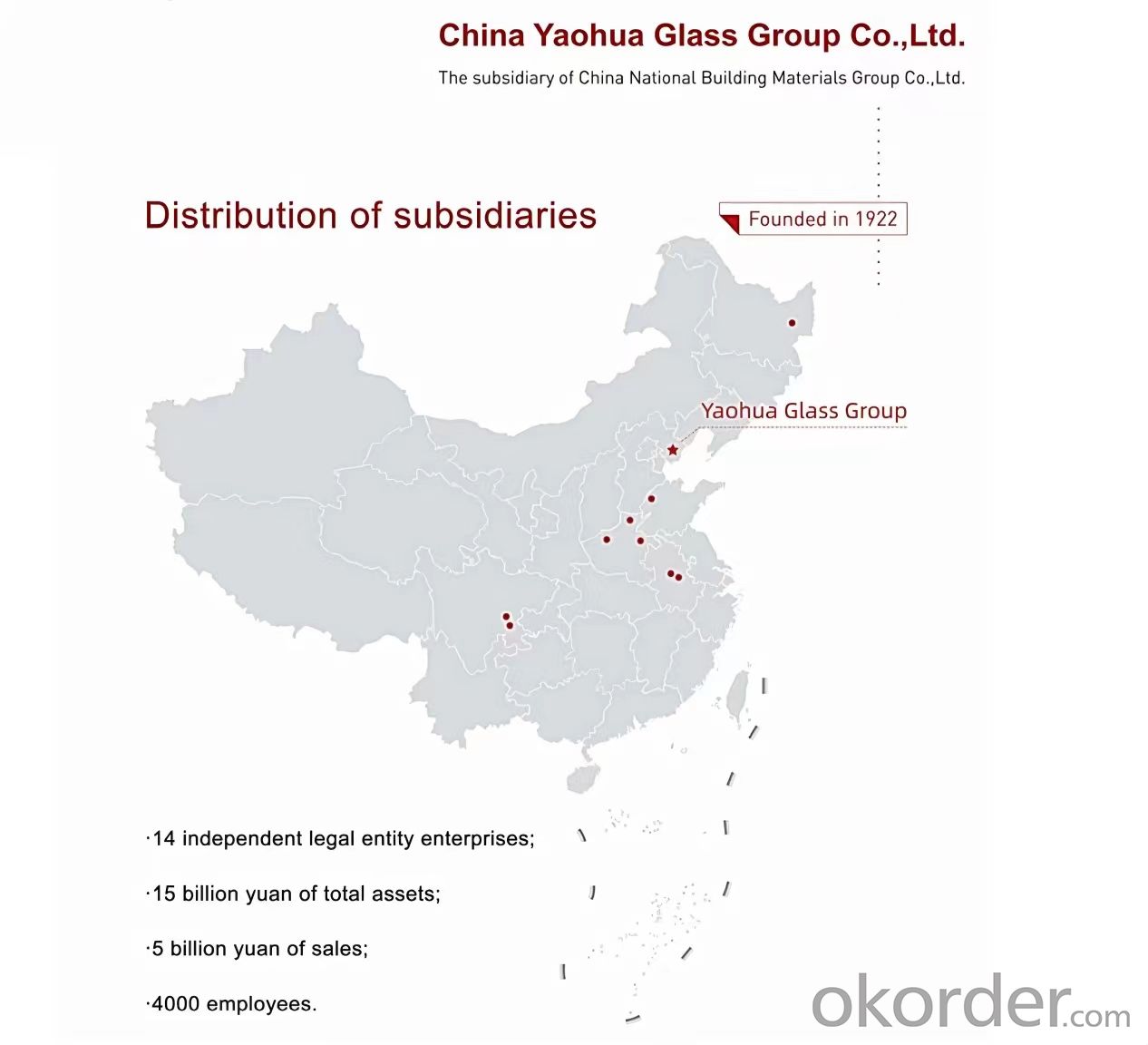

China Yaohua Glass Group Co., Ltd.

Founded in 1922, China Yaohua Glass Group Co., Ltd. (hereinafter referred to as "Yaohua Group”) is a second-tier subsidiary of Triumph Science&Technology Co. ,Ltd. It is the first manufacturer in Asia to continuously produce flat glass by machine,and is known as “the cradle of Chinese glass industry”.

Yaohua Group, as the core platform of Triumph Science & Technology Group for high-quality float and special glass, now has 14independent legal entity enterprises, with assets of over 10-billion-yuan, annual revenue of more than 5 billion yuan and total annual profit of more than 1 billion yuan. The group covers 10 prefecture-level cities in six provinces including Heilongjiang, Hebei, Shandong., Henan, Anhui and Sichuan, with 4000 employees.

It has three sectors float glass, special glass and deep-processing glass. The special glass unties composed of ENGYANG TRIUMPH SILICON MATERIALS CO., LTD. 、 Qinhuangdao Scinan Specialty Glass Co., Ltd.、Triumph Bnegbu Glass Co., Ltd. and CNBM(PUYANG) PHOTOELECTRIC MATERIALS CO., LTD.

Qinhuangdao Scinan Specialty Glass Co., Ltd.

Company Introduction

Founded in 2009 with 65.47 million registered capital and 162 employees, Qinhuangdao Scinan Specialty Glass Co.,Ltd. formerly known as “Qinhuangdao Yaohua Special Glass Co., Ltd.”. The company’s leading products borosilicate flat glass, the annual production capacity of 16425 tons, the products to 3.3 borosilicate flat glass based.

Qinhuangdao Scinan Specialty Glass Co.,Ltd. has researched and developed borosilicate glass products for about 20 years, and has a technical team with excellent professional knowledge and rich experience.

Located in Funing District, Qinhuangdao, the new park is expected to have an annual production capacity of 17,520 tons. It plans to produce 2.6 borosilicate and 3.3 borosilicate glass for household appliances, and 4.0 borosilicate fire-resistant glass. The project is expected to be completed by the end of 23 years.

Our service

We provide high-quality services throughout the process:

Before sales, we provide professional product introduction

In sales, we provide high-quality products

After sales, we have a perfect after-sales system

Our advantage

It is the first high-tech enterprise in China to produce borosilicate flat glass products by full electrofusion technology. At present, the domestic market share industry ranks first. The core technology of the production line is self-developed, the key equipment is the most advanced industrial products, the company set borosilicate flat glass production, processing, sales and service as one, sales network has been spread throughout the country and many countries and regions of the world.

- Q:Architectural painting Mark pen window how to draw

- There is a way to draw the sky, or a small outdoor outdoors, and then draw the shape of the window. Then you can then use (and can not) color lead simply deal with a little texture.

- Q:My new house all the glass without the 3C logo, is not unqualified?

- Property funny funny, actually come up with this naive ridiculous argument to come. Tempered glass will play 3c, but can also choose not to play. For the tempered glass is certainly not 3c. Do you understand that?

- Q:Can architectural glass film be attached to a private car?

- Can be, and much better than the ordinary car to buy: Building film and car film are glass film, structure and application process is basically the same, have a safe, explosion-proof, heat insulation effect, if the market that we can interoperate, this is a consumer misunderstanding. The difference is that: 1, different glial: automotive film is a common adhesive (HPR) and the majority of the building film for the Qing Dynasty gum (CDF) and the safety film is used more adhesive paste, due to different nature, the car film The service life is about 3-5 years, while the building film is normally used for more than 20 years. 2, the metal content requirements are not the same, the volume of cadmium nickel and titanium can not exceed 5%, the building film can not exceed 2%, in this request only in line with the overall requirements of environmental protection, because the driving car is generally adults and healthy people, And people can not live long life in the car, and the building room, including pregnant women, babies and sick and sick people, rare metal radiation on the fetus, the baby's growth there is a certain impact, so the building film rare metal content can not exceed , Should follow the strict environmental protection standards. 3, car film and building film can be separated from ultraviolet light, but the absorption of UV layer structure is not the same, car film separated by ultraviolet layer, is a high-pressure coating a single layer, building film separated by ultraviolet layer is a vacuum sandwich, containing trace plutonium, Harmful spectrum, tuned spectrum video, car film only in the UV UA play a role in the building film UA and VB are working. 4, building film and car film thickness is not the same, the building insulation explosion-proof membrane is usually between 2mil-16mil, the general thickness of 2mil, 4mil, 4.5mil, 8mil, 9mil, 12mil, 14mil, 16mil and so on. Domestic thermal insulation film is usually only between 0.8mil - 1.5mil.

- Q:Building glass specification is that set?

- (JGJ 113-2009), "Construction Safety Glass Management Regulations" (Development and Reform Commission [2003] No. 2116), "Specification for Design, Construction and Acceptance of Aluminum Alloy Doors and Windows", "Regulations for the Application of Building Glass" (JGJ 113-2009) (DBJ15-30-2002).

- Q:Can acrylic panels do roofing materials?

- Using a new type of polyester material, by hot-forming or plane trim, metal base built-in light source, great visual impact. Weathering: panel coated with high concentrations of UV absorbers, metal base sprayed imported car paint, can be long lasting weather, never fade, the service life of up to 5 to 8 years. Durability: The product has a good protection against the built-in light source, extending the service life of the light source. Reasonable: rational design, rain and moisture; open structure, easy maintenance. Impact resistance: 200 times the glass product, almost no risk of fracture. Transparency: up to 93%, translucent excellent, soft light, bright. Flammability: Non-flammable and self-extinguishing. Aesthetics: exquisite craft, the whole font was mirror effect, the base without wrinkles, no seams, all riveting firmware is not exposed. Energy-saving: light transmission performance, the corresponding reduction in light source products, electricity, reduce the use of cost. Talk about plexiglass acrylic (acrylic) PMMA commonly known as plexiglass, also known as acrylic or acrylic, Hong Kong people called Acrylic, is an important early development of thermoplastic, with good transparency, chemical stability and weather resistance, easy to dye, easy Processing, beautiful appearance, in the construction industry has a wide range of applications. Plexiglass products can usually be divided into casting plates, extruded plates and molding compounds.

- Q:Introduction to Building Membrane Materials

- Building film is the use of PET (polyethylene) substrate, leading the use of multi-layer metal sputtering technology and vacuum technology and ion technology and thin film physics, fine chemical technology, it has a very high heat insulation efficiency, high tension, Strong acid and alkali resistance. And the color is rich natural, the test results show that: can block 81% of the solar energy; in the outdoor temperature of 38 ℃ ~ 39 ℃, lower than the average glass temperature of 3.5 ℃, saving more than 30% of the air conditioning power consumption, Energy - saving safety materials.

- Q:How to solve the summer heat insulation problem Like the kind of all-glass sun room, but afraid of the summer is too hot, there is no way both glass sun room transparent, but also solve the sun room insulation problem.

- Glass on the film or use LOW-E glass. This can block the sun's ultraviolet rays, so as to achieve the purpose of insulation.

- Q:What is glass called glass?

- Laminated glass, is between the two pieces of glass into a layer of polyvinyl butyral as the main component of the PVB interlayer. Even if the glass fragmentation, debris will be sticky on the film, the broken glass surface remains clean Smooth, which effectively prevents the debris from falling and penetrating the occurrence of falling events, ensuring personal safety.

- Q:Is nano-glass insulated paint a lie?

- Quite a mixed bag, not to say. But not nothing at all.

- Q:Thickness and specification of glass curtain wall in architectural drawings

- Glass is double insulated glass, 12 + 8a + 8, said the first layer of glass 12mm thick and then 8mm air, (a said air, air; atmosphere)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Borosilicate 3.3 Heat-resistant Glass(Microwave oven glass panel,glass tray)

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000000 pc/month

- Option:

- 2mm-20mm

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords

Qinhuangdao Scinan Special Glass Co., Ltd.

Qinhuangdao Scinan Special Glass Co., Ltd.