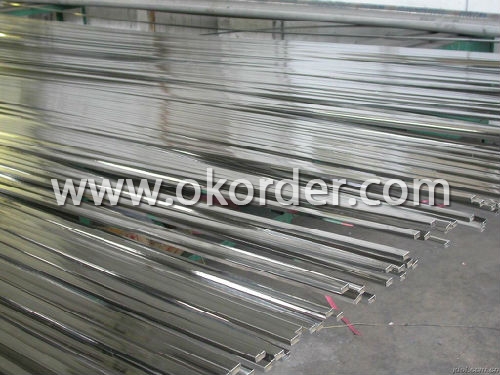

304 Stainless Steel Flats

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

304 Stainless Steel Flats

1.Standard:

AISI, GB, JIS, ASTM, DIN, EN

2. Grade:

1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:

3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1000kg

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application:

These products are widely supplied to areas of machine made industry, chemical industry, shipping industry,architecture, food industry, household products etc

Name | Stainless Steel Flat Bar | ||||||||

Material | 201.202.301.304.304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H,etc. | ||||||||

Standard | JIS/AISI/ ASTM,/GB,/DIN,/EN/SUS.etc. | ||||||||

Shape |

Stainless steel Round/flat/square/angle/hexagonal bar | ||||||||

Price term |

FOB/CIF/CNF or as required | ||||||||

Length | 6m,5.8m,4m as required | ||||||||

Application | kitchen and sanitary wares , and Structural use high strength components,furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc | ||||||||

Payment terms | L/C,T/T,Western Union,or as required. | ||||||||

MOQ | As required | ||||||||

Packing | Export standard package | ||||||||

Certificate | ISO/SGS | ||||||||

Contact | If you are interested in our products,please feel free to contact me. |

- Q:What is the difference between 17-4PH and 15-5PH stainless steel pipes?

- The chemical composition and mechanical properties are the main factors that distinguish 17-4PH and 15-5PH stainless steel pipes. Regarding 17-4PH stainless steel, it is a precipitation-hardening grade that comprises 17% chromium, 4% nickel, 4% copper, and a small amount of molybdenum. This grade is renowned for its exceptional combination of high strength and resistance to corrosion. Additionally, it can be subjected to heat treatment to achieve varying levels of hardness, making it suitable for diverse applications that necessitate strength and corrosion resistance. On the contrary, 15-5PH stainless steel is also a precipitation-hardening grade but possesses a slightly different composition. It consists of 15% chromium, 5% nickel, and 3-5% copper. This grade offers good strength, toughness, and corrosion resistance, comparable to 17-4PH stainless steel. However, it exhibits a higher level of toughness and better resistance to stress corrosion cracking. In terms of mechanical properties, 17-4PH stainless steel generally exhibits greater strength and hardness compared to 15-5PH stainless steel. It can be subjected to heat treatment to achieve a wide range of hardness levels, including high strength and hardness suitable for demanding applications. On the other hand, 15-5PH stainless steel, although still possessing good strength, typically does not undergo the same extent of heat treatment as 17-4PH. Both 17-4PH and 15-5PH stainless steel pipes find common usage in industries such as aerospace, oil and gas, and chemical processing, where their combination of strength and corrosion resistance proves highly advantageous. The choice between the two grades depends on specific application requirements, with 17-4PH offering greater strength and hardness versatility, while 15-5PH provides better resistance to stress corrosion cracking and improved toughness.

- Q:Are stainless steel pipes suitable for water treatment plants?

- Indeed, water treatment plants find stainless steel pipes to be a fitting choice. Stainless steel possesses resistance against corrosion, enabling it to endure the harsh circumstances commonly present within water treatment plants, such as exposure to chemicals, high temperatures, and high pressure. Moreover, its durability is exceptional, guaranteeing an extended lifespan and diminishing the necessity for frequent replacements. The smooth inner surface of stainless steel pipes further prevents the accumulation of deposits and enhances the efficiency of water flow. Furthermore, stainless steel upholds hygienic standards and refrains from leaching harmful substances into the water, thus ensuring the quality and safety of the treated water.

- Q:How are stainless steel pipes joined together?

- Stainless steel pipes are joined together through various methods such as welding, threading, and compression fittings.

- Q:How do you clean and maintain stainless steel pipes?

- To clean and maintain stainless steel pipes, start by wiping them down with a mild detergent or soap and warm water using a soft cloth or sponge. Rinse thoroughly and dry with a clean cloth to prevent water spots. Avoid using abrasive cleaners or scrub brushes that can scratch the surface. Regularly inspect the pipes for any signs of corrosion, staining, or damage, and promptly address any issues to prevent further deterioration. Additionally, applying a stainless steel cleaner or polish can help remove stubborn stains and restore the shine of the pipes.

- Q:What is the difference between Type 304 and Type 316 stainless steel pipes?

- Type 304 and Type 316 stainless steel pipes are both widely used in various industries, but they differ in terms of their composition and physical properties. Type 304 stainless steel is a versatile and commonly used grade of stainless steel pipe. It contains a higher percentage of chromium and nickel compared to Type 316, which gives it excellent corrosion resistance and durability. Type 304 is ideal for applications where exposure to corrosive substances is minimal, such as in indoor environments or for general-purpose use. On the other hand, Type 316 stainless steel is known for its superior corrosion resistance, especially in more aggressive environments. It contains a higher percentage of molybdenum, which enhances its resistance to pitting and crevice corrosion caused by chloride solutions, such as seawater or saltwater environments. This makes Type 316 stainless steel pipes suitable for marine applications, chemical processing plants, and applications where the piping will be exposed to harsh chemicals or high temperatures. In terms of physical properties, Type 316 stainless steel pipes have higher tensile strength and yield strength compared to Type 304. This means that Type 316 pipes can withstand higher pressures and have better resistance to deformation or cracking under stress. In summary, the main difference between Type 304 and Type 316 stainless steel pipes lies in their corrosion resistance and physical properties. Type 304 is suitable for general-purpose use and indoor environments, while Type 316 is preferred for applications where superior corrosion resistance and strength are required, especially in aggressive or high-temperature environments.

- Q:What is the difference between Type 304H and Type 316H stainless steel pipes?

- Type 304H and Type 316H stainless steel pipes are both high carbon versions of their respective stainless steel grades. However, there are some key differences between the two. Firstly, Type 304H stainless steel pipe is an austenitic stainless steel that contains 18-20% chromium and 8-10.5% nickel. It also has a maximum carbon content of 0.04-0.10%, which provides improved high-temperature strength and resistance to sensitization (a process that can occur when stainless steel is exposed to high temperatures, leading to grain boundary corrosion). This makes Type 304H suitable for high-temperature applications, such as in the chemical processing industry. On the other hand, Type 316H stainless steel pipe is also an austenitic stainless steel, but it contains higher levels of chromium (16-18%), nickel (10-14%), and molybdenum (2-3%). The addition of molybdenum enhances the corrosion resistance of Type 316H, especially in chloride environments. This makes Type 316H suitable for applications that require excellent resistance to corrosion, such as in marine environments or in the presence of acidic or alkaline solutions. In summary, the main difference between Type 304H and Type 316H stainless steel pipes lies in their chemical compositions and resulting properties. Type 304H offers improved high-temperature strength and resistance to sensitization, while Type 316H offers enhanced resistance to corrosion, especially in chloride environments. The choice between the two will depend on the specific requirements of the application, such as temperature, corrosion resistance, and environmental conditions.

- Q:What is the maximum pressure rating for stainless steel pipe fittings?

- There are several factors that contribute to the maximum pressure rating of stainless steel pipe fittings, including the material grade, size, and temperature. In general, stainless steel pipe fittings have the ability to handle high-pressure applications due to their strength and resistance to corrosion. The pressure rating of these fittings can vary greatly, ranging from 150 psi to as high as 10,000 psi, depending on the specific fitting and its intended use. To determine the maximum pressure rating for a particular stainless steel pipe fitting, it is important to refer to the manufacturer's documentation or industry standards such as ASME B16.11 or ASME B16.9. Additionally, when working with high-pressure systems, other factors such as the sealing method, compatibility with the conveyed fluid, and any necessary safety precautions must be taken into consideration.

- Q:What is the difference between the stainless steel tube and tube rolling

- We usually say the hot-rolled seamless slide into thermal expansion, is to use tools of the pipe up, supporting circle. Cold is the opposite, a fixed mould outside the inner hole of the fixed mandrel, from the outside to make him thinner. Annealing is required before hot rolling, without cold rolling. In hot rolling billet after annealing, stainless steel seamless pipe, wall production minus a broaching machine after reaming compression capability, good flexibility, technological properties were superior to those of ordinary tube ligation.Now the Zhejiang area in the production of stainless steel seamless pipe is widely used cold production technology, but higher production efficiency of 2 roller cold rolling mill, a lot of strength of the manufacturers are equipped with, because the price of the purchase quantity not more general factory. It is commonly used in conjunction with cold drawn units to increase efficiency and reduce production costs.It is precisely because of their differences in production and processing technology, but also makes the hot-rolled stainless steel and cold-rolled pipe has the following differences:A: seamless pipe and tube rolling produced products, though they are working with the tube, but the application is different, generally used for mechanical drawing, heat exchanger pipe, pipe and tube rolling engineering, generally used for fluid transport in pipeline construction;Two: seamless pipe and tube rolling process and product quality; slide processing, low defect, high precision, uniform grain size;Three: two different prices, the price to slide rolling ratio is more expensive;Four: the stainless steel tube ligation can only in diameter 38-159 pipe, or other drawing process. Because of the production process, the tube size is relatively accurate. In the purchase of steel tubes, or tube rolling is drawing, but also the actual situation needs to choose.

- Q:What is the external insulation used for stainless steel pipes?

- The external insulation used for stainless steel pipes is typically made of a variety of materials such as mineral wool, fiberglass, or foam. These insulating materials are applied to the exterior surface of the stainless steel pipes to provide thermal insulation and protect against heat loss or gain. The insulation helps to maintain the temperature of the fluid or substance flowing through the pipes, preventing condensation and reducing energy loss. Additionally, the external insulation can also provide protection against corrosion and mechanical damage, ensuring the longevity and efficiency of the stainless steel pipes.

- Q:What are the different types of stainless steel pipe gaskets?

- There are several different types of stainless steel pipe gaskets available, each designed to meet specific needs and requirements. Some of the most common types include: 1. Ring Type Joint (RTJ) Gaskets: These gaskets are used in high-pressure applications and are designed to withstand extreme temperatures and pressures. They feature a metallic ring with a soft sealing layer, which ensures a tight and reliable seal. 2. Spiral Wound Gaskets: This type of gasket is made by winding a metal strip and a filler material in a spiral shape. The metal strip provides strength and stability, while the filler material ensures a proper seal. Spiral wound gaskets are suitable for a wide range of applications, including high temperature and pressure environments. 3. Metal Jacketed Gaskets: These gaskets consist of a soft filler material enclosed in a metal jacket. The metal jacket provides additional strength and protection, making them suitable for high-pressure applications. Metal jacketed gaskets are commonly used in flange connections. 4. Camprofile Gaskets: Camprofile gaskets are composed of a metal core with concentric grooves on both sides. These grooves are filled with a soft sealing material, which provides an effective seal. They are commonly used in applications where high temperature and pressure resistance is required. 5. Double Jacketed Gaskets: Double jacketed gaskets consist of two metal jackets with a soft filler material in between. This design provides enhanced sealing performance and is often used in applications involving high temperatures and pressures, as well as corrosive environments. 6. Elastomeric Gaskets: These gaskets are made from a variety of elastomeric materials such as rubber or silicone. They are commonly used in low-pressure applications and provide excellent sealing properties. Elastomeric gaskets are cost-effective and easy to install. It is important to select the appropriate type of stainless steel pipe gasket based on the specific application requirements, including temperature, pressure, and the nature of the fluid being transported. Consulting with a knowledgeable supplier or engineer can help ensure the correct gasket is chosen for the intended use.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

304 Stainless Steel Flats

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords